Considering raising demand for shampoo bottle, Hitech Plastics Engineering offers complete solution for shampoo bottle manufacturing. Currently, shampoo bottle manufacturing has become one of the trending profitable business. It cannot be overstated that the process of selecting the appropriate machine combination for your plastics application is a critical part of the success or failure of any particular machine cell. Hitech Plastics Engineering offers the economical solution for shampoo bottle manufacturing so that customer can survive in highly competitive marketplace. The company takes into consideration both your business goals and the needs of your customers with the ultimate goal of providing an up front design analysis for a higher-quality finished product, customized to meet cost and performance targets.

Why Only Hi-tech Plastics Engineering?:

- Single Source Provider: You can get a range of options and can select best one.

- Consulting Specialists: They can help you determine the most effective equipment to increase your production throughput.

- Technical Assistance & Support: Hitech Plastics Engineering’s dedication to your project does not stop after installation. Our professionals are always ready to relieve burden from your shoulder and provide support even after office hours.

- Deals in World-Known Brands: As a authorized dealer of renowned brands, Hitech Plastics Engineering guarantee all equipment.

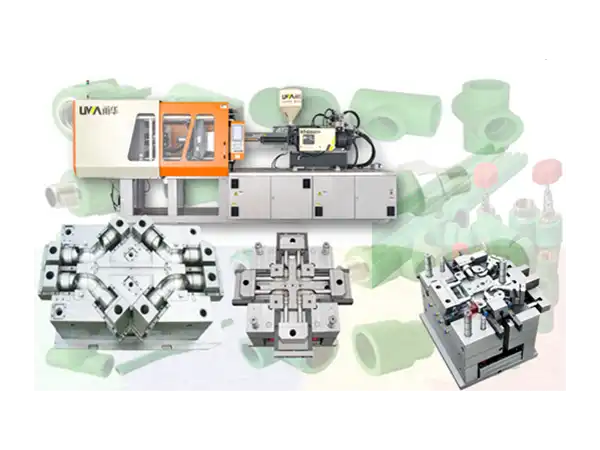

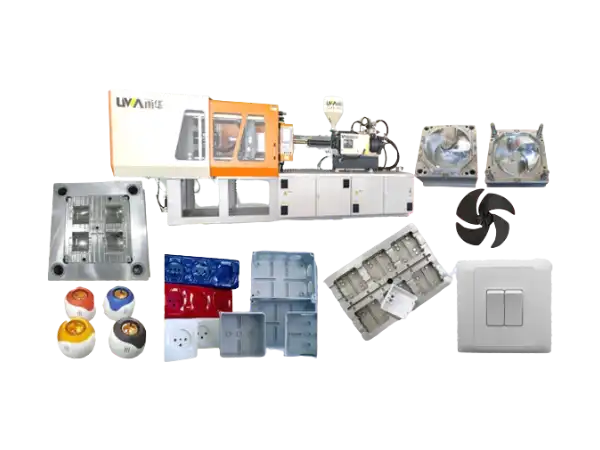

Double Color Injection Moulding Machine

Double Color Injection Molding Machine

- Servo system

- Rotating platen

- Oil level alarm

- Self-lock suction oil filter

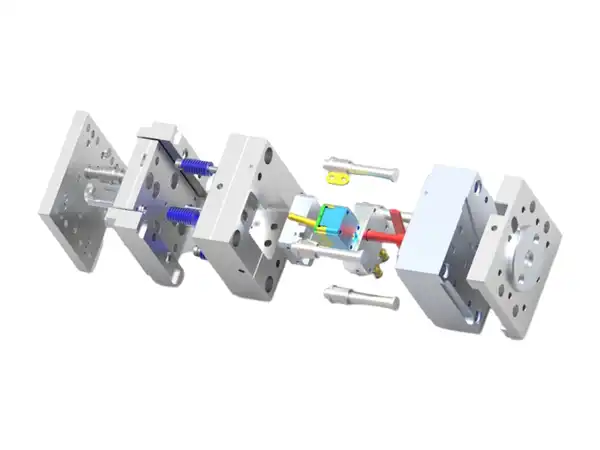

Mould Features:

- Double Color Mold 08 cavity

- Cycle Time: 18-20 seconds

- Mould Core & Cavity Material: S136

- Mould Base Material: P20H

| D280Db/p/M370+M150 | |||

|---|---|---|---|

| Specifications | M370 | M150 | |

| Clamping Unit | |||

| Clamping Force | KN | 2800 | |

| Clamping Stroke | mm | 490 | |

| Tie Bar Distance | mm | 920*570 | |

| Max. Mould Height | mm | 520 | |

| Min. Mould Height | mm | 200 | |

| Eject Stroke | mm | 130 | |

| Eject Force | KN | 34 | |

| No. of Ejector Pins | Pcs | 3+3 | |

| Rotation Platen Diameter | mm | 1000 | |

| Injection Unit | |||

| Screw Diameter | mm | 38 | 25 |

| Screw L/D ratio | 20 | 22 | |

| Shot Size(Theoretical) | cm3 | 198 | 62 |

| Injection Weight (PS) | g | 181 | 56 |

| Injection Pressure | MPa | 189 | 309 |

| Injection Rate into Air | g/s | 114 | 70 |

| Injection Stroke | mm | 175 | 143 |

| Injection Speed | mm/s | 101 | 126 |

| Screw Rotation Speed | rpm | 218 | 304 |

| Others | |||

| Max. pump pressure | MPa | 17.5 | 17.5 |

| Pump Power Motor | KW | 13+13 | 13+13 |

| Heater Power | KW | 6.6 | 4.5 |

| Hopper capacity | kg | 25 | 25 |

| Oil tank capacity | L | 350 | 350 |