SCREW AIR

HiTECH MACHINERY

SHANGHAI CO. LTD is a high-tech Japanese joint venture with independent intellectual property, founded in 2000. SCR together with Anest Iwata focuses on air compressor air filter research and development, covering all aspects from manufacturing through to sales, service, and technical support.

SCR supplies a complete range of products such as high efficiency permanent magnet variable speed screw compressors, oil free air compressors, oil-free scroll compressors, bearing free and magnetic centrifugal blowers.

The global sales and service network provides our customers with high-quality, energy efficient, and environmentally friendly screw compressed air solutions. We are proud of our commitment to quality and customer service. Our customers are the foundation of our business, and we strive to meet their needs and exceed their expectations at Plastic machinery.

Strategic Cooperation

With ANEST IWATA

Provided more than 50,000 companies with screw air compressor products, highly praised for its energy efficiency and quality. Plastic machinery is essential to many different sectors because it promotes efficiency and creativity. These devices are necessary in the plastic manufacturing sector to produce high-quality plastic components. They provide accurate and long-lasting parts to the power plant industry, power station industry, textile industry, cement industry, and automotive industry.

One of the top producers of plastic molding machines for usage in a variety of industries is HiTech Machinery. Energy-saving technology is included in the design of our equipment, and our compressor line offers premium oil-injected systems for optimal performance. Our possession of prestigious industry awards attests to our dedication to quality. Furthermore, we offer outstanding customer service and robust marketing defense, guaranteeing our clients receive all-encompassing assistance and competitive market positioning.

Here at HiTech Machinery, we take great satisfaction in being industry leaders in the production of plastic molding machinery for a variety of applications. Throughout the years, we have been awarded several accolades and certificates that attest to our dedication to quality. This collection demonstrates our commitment to quality, innovation, and customer happiness and serves as evidence of the exceptional accomplishments that have brought us acclaim and validation within the industry.

Plastic machinery delivers unparalleled performance with its screw air compressors, ranging from 7.5 kW to 315 kW, offering a versatile solution for industries. With pressure options from 7 to 16 bar, these compressors ensure optimal efficiency across a spectrum of applications.

APM Technology's Impact on the Next Generation of Screw Air Compressors Air Filter.

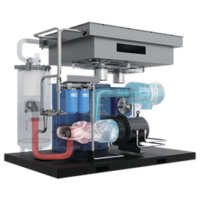

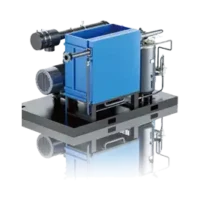

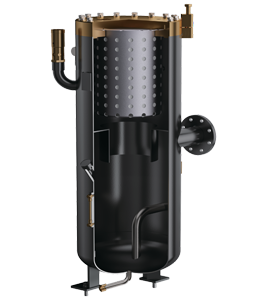

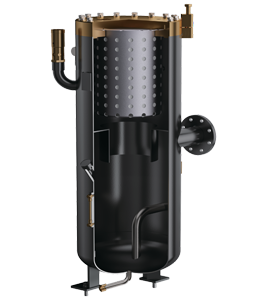

The use of a large-capacity air tank can reduce the periodic pul-sating airflow of the compressor exhaust,stabilize the pressure in the compressor air pipe, reduce the start frequency of the air compressor, protect the air compressor, and reserve air at the same time.

Large capacity air tank

SCRIOAPM 300L

SCR15/20APM 500L

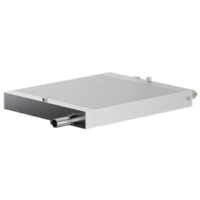

The high heat exchange efficiency design of the inlet and outlet temperature difference of 5 C reduces the demand for cooling capacity to a low level and achieves a high energy efficiency ratio. The stainless plate heat exchanger prevents the dryer from becoming a pollution source and achieves high-quality compressed air.

Efficient Heat Transfer

Efficient heat transfer capacity and the use of environ-mentally friendly refrigerant R134a makes it especially be suitable for high temperature and high humidity envi-ronment.

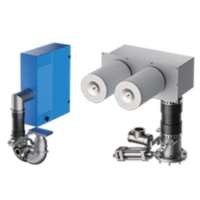

High precision triple filter Remove solid particles down to 0.01m.reach the maximum residual oil content of 0.01ppm and provide high-quality compressed air.

The heavy-duty air filter is carefully designed to be suitable for medium and heavy dust load environmental conditions.

Oversize cooler makes sure the compressor can run max up to 46 degrees without any problem.

A customized controller specially developed for permanent magnet motors. which is more in line with compressor needs

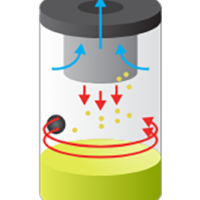

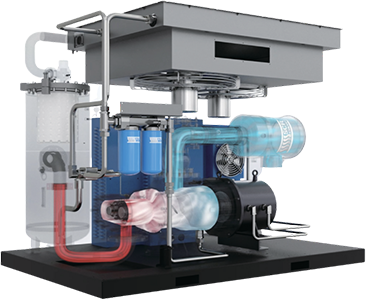

The Row guide plate changes flow direction, and the cross collision makes the small oil particles combine into large oil particles to separate, reduce the burden on the oil-gas separator layer, and extend the life of the oil separator Reserved more than 30% margin of the oil-separator Efficiency is increased by 1-2% Vertical tangential structure separator.

The first stage is mechanical centrifugal separation. The second stage is a high-efficiency oil separator. 4000hours life span of oil separator. The oil content is lower than 3PPM.

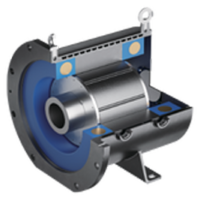

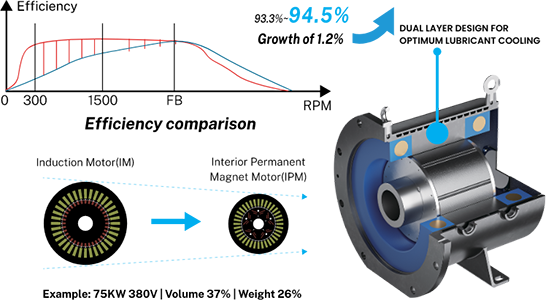

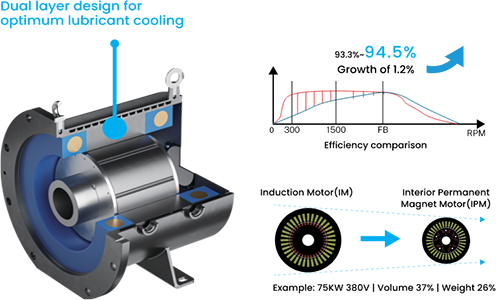

Oil-cooled motor. ReachlE4 efficiency standard. VSD: variable speed drive. Bearing a free motor requires zero maintenance. UH series Permanent magnets resist to 180 °C. Fully enclosed IP65 protection. Optimal cooling for all speeds and ambient conditions. F-grade insulation and B-grade temperature rise assessment. The high-temperature design prevents demagnetization.

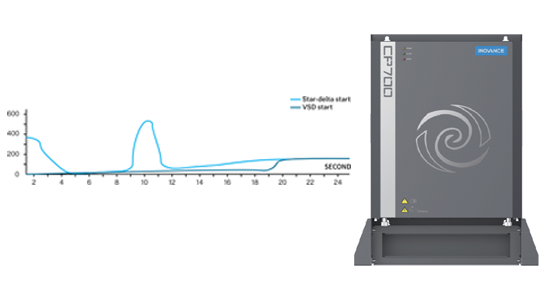

SCR APM Series adopts a soft start system for its start-up. The inovance VSD maintains full load current on start up to 1.5 times FLC-Traditional motor starters such as direct on-line starters and star delta starters burden the power supply due to the high peak start up current which can typically be 8-10 times FLC. With variable speed soft start system, the starting current never exceeds the rated value.

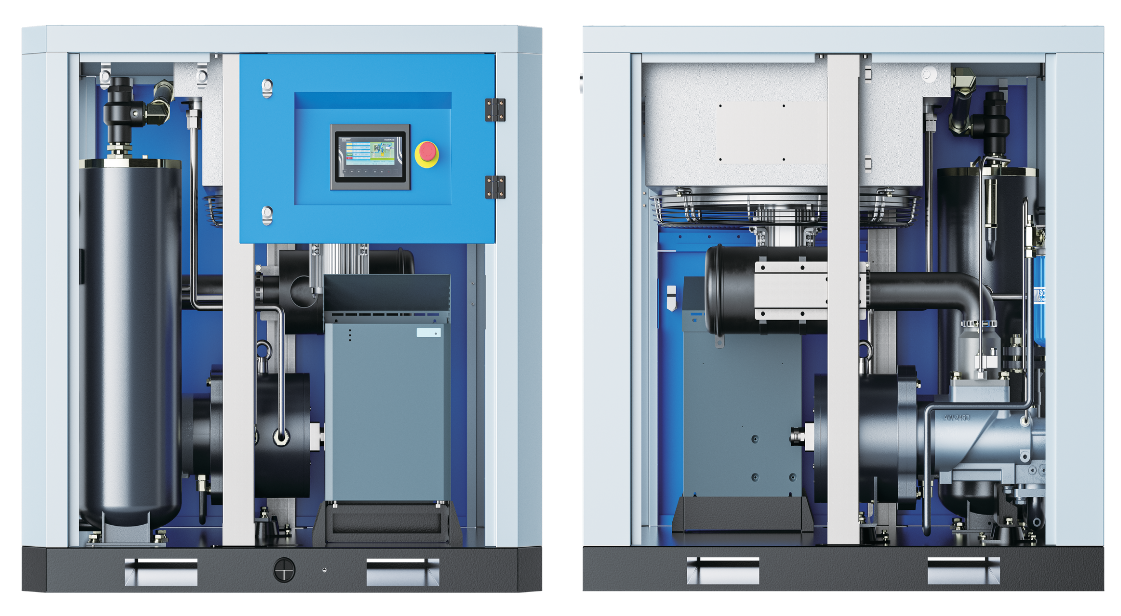

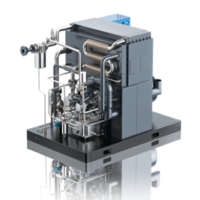

The APM Series introduces a groundbreaking range of screw air compressors, designed to meet the diverse needs of industrial applications. From compact models catering to space constraints to high-capacity units for heavy-duty operations, the APM Series offers a complete spectrum of options.

MOTOR POWER

PRESSURE

Explore plastic machinery and the flexibility of the APM Series, where cutting-edge engineering meets a commitment to excellence. Tailored to suit various industries, these compressors boast user-friendly interfaces, low maintenance requirements, and a seamless integration of smart features.

MOTOR POWER

PRESSURE

Experience the future of air compression with Hitech's PM & PM2 Series.

SCR's Energy-saving screw compressor is designed with one thing in mind, to provide a highly efficient and optimum product. Coupling the latest compressor technology and SCR's innovative design team, the SCR Energy-saving screw compressor exceeds previous models in terms of power optimization and energy efficiency, while at the same time reducing cost.

Exceed 1E4 standards Lubricant-cooled motor USD: variable ive speed dr Bearing free motor requires zero maintenance UH series Permanent magnets resist to 180 t Fully enclosed 1P85 protection Optimal cooling for all speeds and ambient conditions F grade Insulation and 8 grade temperature rise assessment High temperature design prevents demagnetization.

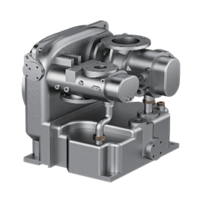

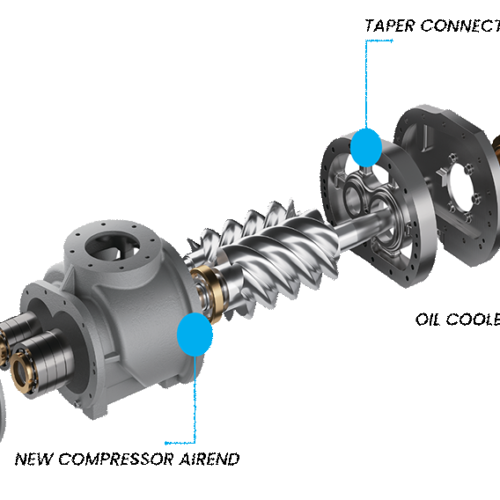

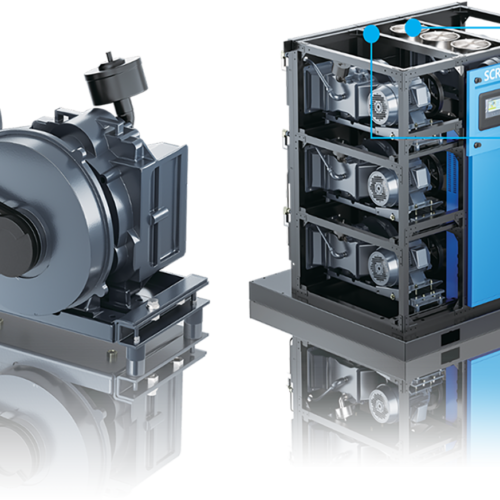

Motor rotor is taper connection with airend male rotor. No gears or belts, no shaft seal,no coupling. Zero transmission loss. Easy for installation and maintenancce. No need to make alignment adjustment. Better protection for inner parts of PM motor. Reduce maintenance cost.

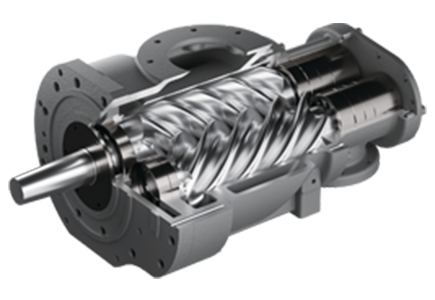

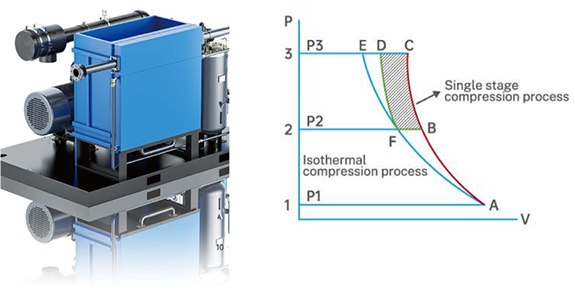

New improved rotor profile. R&D in Japan. Isothermal compression. Multi point atomization injection technology. Reduced pressure losses. Optimized in and outlet portals. Designed for 20 years* of reliable operation. Flow-optimized for impressive performance. All-new, state-of-the-art airend improves. Efficiency as much as 16%.

SCR PM compressors have a wide operating speed range leading to stable constant pressure control further reducing power consumption. SCR’s exclusive inverter and Energy Saving Logic control can get optimized energy savings, regardless of the load condition. They can react to pressure changes quickly maintaining pressure fluctuation to ±0.01 MPa.

Constant temperature setting ensures the best lubrication performance avoiding high temperature trips.

Reduce the ingress of foreign matter preventing the cooler from blocking Extend the service life of the compressor

Large rotor low speed effectively reduces air vibration and noise VSD air compressor starts and runs steadily without frequent loading and unloading of normal screw compressor Double VSD control (main motor and fan motor double VSD) can reduce the noise of airend and cooling fan Acoustic sound deadening and new cooling system decreases the overall noise level Low noise operation means conversations can take place

Improved user-friendly design. 7.0-inch full color touch LCD screen Real-time Operation/ Maintenance/ Alarm information Graphical flow diagram. Operation record/ Chart display. Multiple languages. Weekly timer/Service history and planning On board RS485 interface

Engineered for precision, Hitech's compressors with 22-75 kW motor power

and adjustable 7/8/10 Bar pressure ensure reliability in diverse

industrial applications."

MOTOR POWER

PRESSURE

Explore the flexibility of the APM Series, where cutting-edge engineering meets a commitment to excellence. Tailored to suit various industries, these compressors boast user-friendly interfaces, low maintenance requirements, and a seamless integration of smart features

MOTOR POWER

PRESSURE

EPM series maximizing precision or the EPM2 series setting new standards in energy conservation, experience elevated performance for a wide range of industrial applications.

Engineered for precision, Hitech's compressors with 22-75 kW motor power and adjustable 7/8/10 Bar pressure ensure reliability in diverse industrial applications."

MOTOR POWER

PRESSURE

Explore the flexibility of the APM Series, where cutting-edge engineering meets a commitment to excellence. Tailored to suit various industries, these compressors boast user-friendly interfaces, low maintenance requirements, and a seamless integration of smart features.

MOTOR POWER

PRESSURE

Experience the future of air compression with Hitech's PM & PM2 Series.

High-Grade Specifications Redefining Standard TEFC motor. IE3 Motor Efficiency. F insulation grade. IP 55 protection grade. SKF bearing. Automatic Grease Replacement (Option). Bearing Temp Monitoring(Option). PM motor For VSD is an Option.

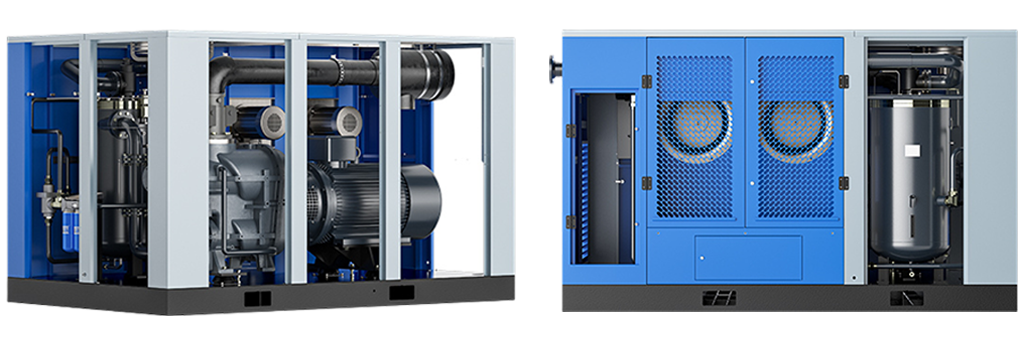

SCR TWO STAGE SERIES compressors have a wide operating speed range leading to stable constant pressure control further reducing power consumption.

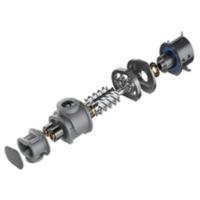

The rotors are meshed and sealed with an oil film belt to reduce wear. R & Din Japan. Reduces the compression ratio with each compression. Reduces Energy Consumption. Low differential pressures.

AFE31is area isothermal compression. AC31 is the area of standard compression. AB. BFFD, 31 is an area of two-stage compression. Two-stage compression saving area is BCDF comparison with standard compression.

More than 30% margin of air filter capacity. Efficiency is improved more than 0.5%.

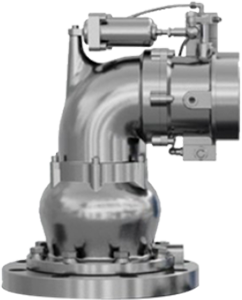

Optimizes the inlet flow of the airend. Efficiency is improved by more than 0.5% Special Inlet Valve designed for the low-pressure application.

The Row guide plate changes flow direction, and the cross collision makes the small oil particles combine into large oil particles to separate, reduce the burden on the oil-gas separator layer, and extend the life of the oil separator Reserved more than 30% margin of the oil-separator Efficiency is increased by 1-2% Vertical tangential structure separator.

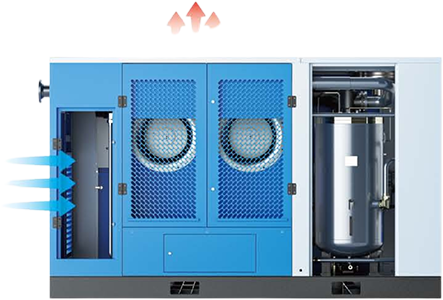

Side air inlet and top air outlet VSD centrifugal fan Centrifugal fan VSD operation according to AMBIENT-2% energy efficiency improvement. Magnetic panel filters Help reduce the ingress of foreign matter preventing the cooler from blocking. Extend the service life of the compressor.

Oil particles can be controlled at 0.1 microns. Ensures a smooth and well-lubricated oil system. Multiple oil filter combinations, enhance stable operation.

Improved user-friendly design. 7.0-inch full color touch LCD screen Real-time Operation/ Maintenance/ Alarm information Graphical flow diagram. Operation record/ Chart display. Multiple languages. Weekly timer/Service history and planning On board RS485 interface

Large rotor low speed effectively reduces air vibration and noise VSD air compressor starts and runs steadily without frequent loading and unloading of normal screw compressor Double VSD control (main motor and fan motor double VSD) can reduce the noise of airend and cooling fan Acoustic sound deadening and new cooling system decreases the overall noise level Low noise operation means conversations can take place

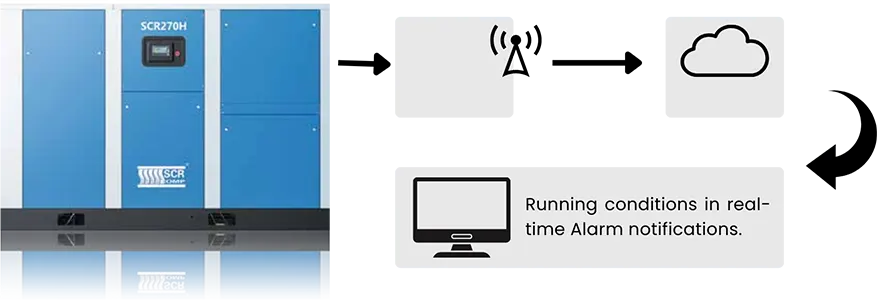

Customers can monitor the live running conditions of SCR compressors anytime, anywhere, and can be accessed through a Cloud service in real-time. Moreover, alarm notifications will help prevent any unplanned downtime.

Experience superior industrial capability with motor power ranging from 90-315 kW and adaptable pressure settings of 7/8/10/12.5 Bar in a two-stage configuration. It is the ideal solution for demanding applications that require power and precision.

MOTOR POWER

PRESSURE

Experience superior industrial capability with motor power ranging from 90-315 kW and adaptable pressure settings of 7/8/10/12.5 Bar in a two-stage configuration. It is the ideal solution for demanding applications that require power and precision.

PRESSURE

MOTOR POWER

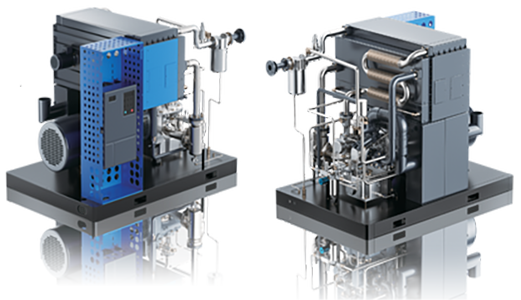

Experience the synergy of power and cleanliness, setting new benchmarks in industrial air compression.

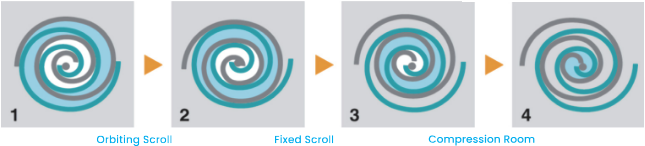

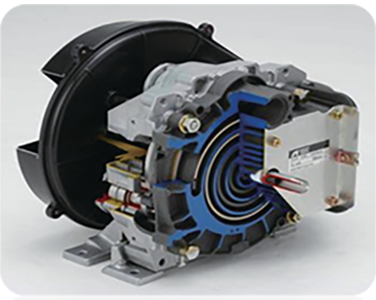

Scroll Airend Compression Principle

Original Japanese ANEST IWATA airend.

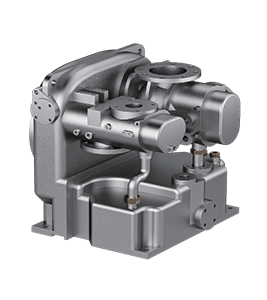

Original German GHH Rand Airend; Stainless Steel Rotor;

Original German GHH Rand Airend; Stainless Steel Rotor;

Dual Sealed;

SKF Bearings;

Long Maintenance Intervals;

Energy Efficient Operation;

Clean 100% Oil free air to Class 0.

Pressure loss of air filter inlet structure <1000Pa. Reliable operation and easy maintenance.

Dry compression often leads to high noise levels particularly at high speed operation. Thanks to the patented Venturi design, noise levels are significantly reduced.

The independent inlet silencer box ensures that the air lter inlet temperature matches the ambient temperature .

Improved user-friendly design. Parameters can be modified without stopping 7 ” touch screen plc. Modbus RTU-protected RS485 interface

Multiple warning and protection functions Energy saving logic Overload/ Over current/ phase loss Pre-alarm system to avoid sudden failure Multiple compressor sequencing capability Remote monitoring capability Programmable start-stop schedules Power consumption data is storaged inside PLC

Board RS485 communication, Intelligent PID ow regulation mode, Accurate torque control, Fast response speed for system pressure, Fast acceleration, and deceleration characteristics, Closed loop dynamic control and high precision control, Constant pressure control avoids generating site air pressure

Customers can monitor the live running conditions of SCR compressors anytime, anywhere and can be accessed through a Cloud service in real time. Moreover, alarm notifications will help prevent any unplanned down time.

Your compressed air standards with our Oil-Free Technology, delivering purity and performance across a dynamic range from 7.5 kW to 75 kW. Engineered for reliability, this series ensures contaminant-free air, making it the ideal choice for critical applications where quality is paramount.

PRESSURE

MOTOR POWER

The realm of Oil-Free Technology, where precision converges with power. Encompassing the 3.7 kW to 45 kW range, this series assures contaminant-free air for critical applications. Redefine your expectations with an optimal blend of efficiency and dependability.

PRESSURE

MOTOR POWER

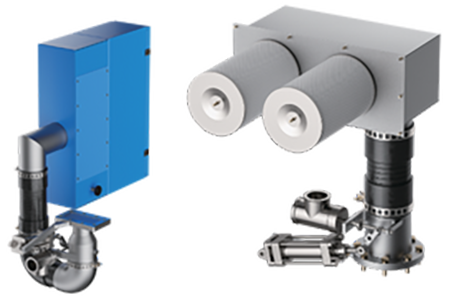

Perfect balance of power and efficiency with our Low-Pressure Compressors.

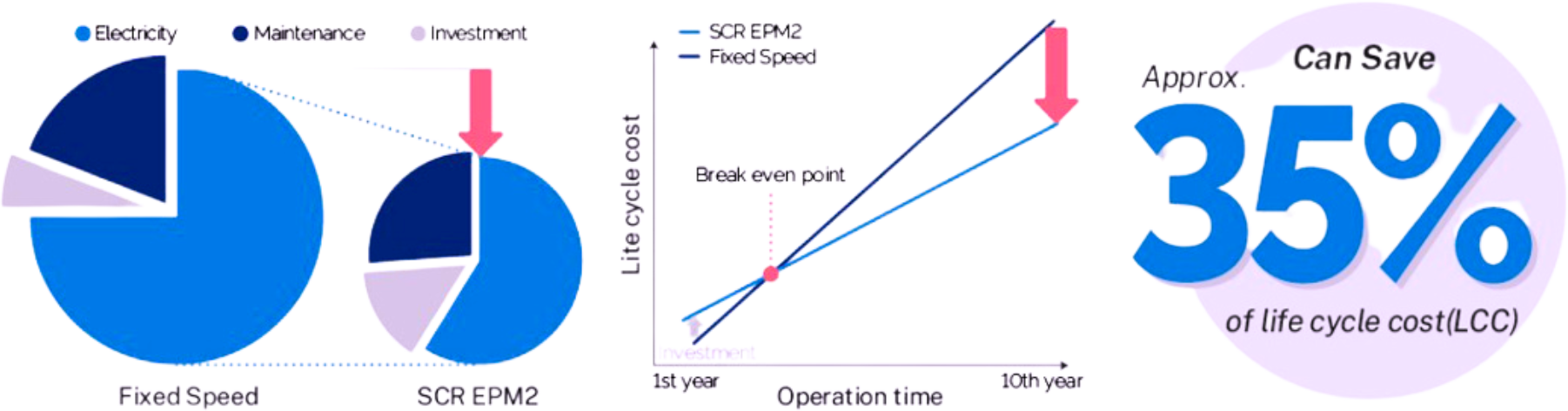

What's important is not the initial cost but the life cycle cost. INVERTER compressors may look more expensive than fixed-speed models. Still, many customers choose them because they know the importance of life cycle cost & return on investment when choosing compressors.

Crafted for versatility and precision, the LBPM Series stands as a testament to customized compressed air solutions. Ranging from 22 kW to 160 kW, these compressors redefine low-pressure applications, offering a tailored approach to efficiency.

MOTOR POWER

PRESSURE

Experience a new standard in safety and performance with the II Series. Engineered for industrial excellence, this multipole safety protection system ensures optimal operation and protection in the 90-200 kW range.

MOTOR POWER

PRESSURE

D Series, featuring high-efficiency airend technology and motor power ranging from 15 kW to 75 kW. Engineered for precision and reliability, this series sets a new standard in compressed air solutions.

MOTOR POWER

PRESSURE

The longevity and effectiveness of plastic molding machines depend on their performance being maintained at its best. Our skilled maintenance programs are designed to extend functionality and reduce downtime. Using authentic components like air filters, oil separators, and oil free air filter compressors, our knowledgeable specialists make sure your plastic machinery runs smoothly and dependably in a variety of industries. You can rely on us to maintain the best possible condition for your plastic machinery, extending its lifespan and output.

To install a screw air compressor or Crusher, ensure it’s on a stable, flat surface and connect it to a power source and air filter system according to the screw compressor manufacturer’s instructions.