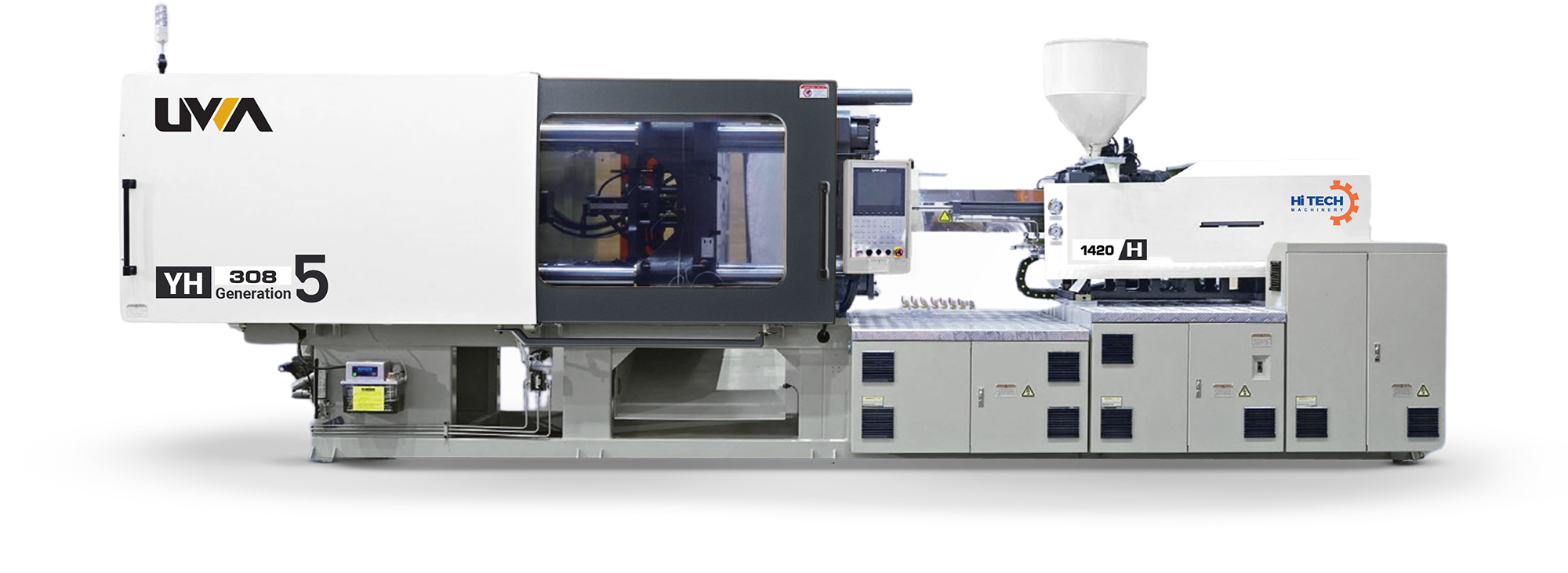

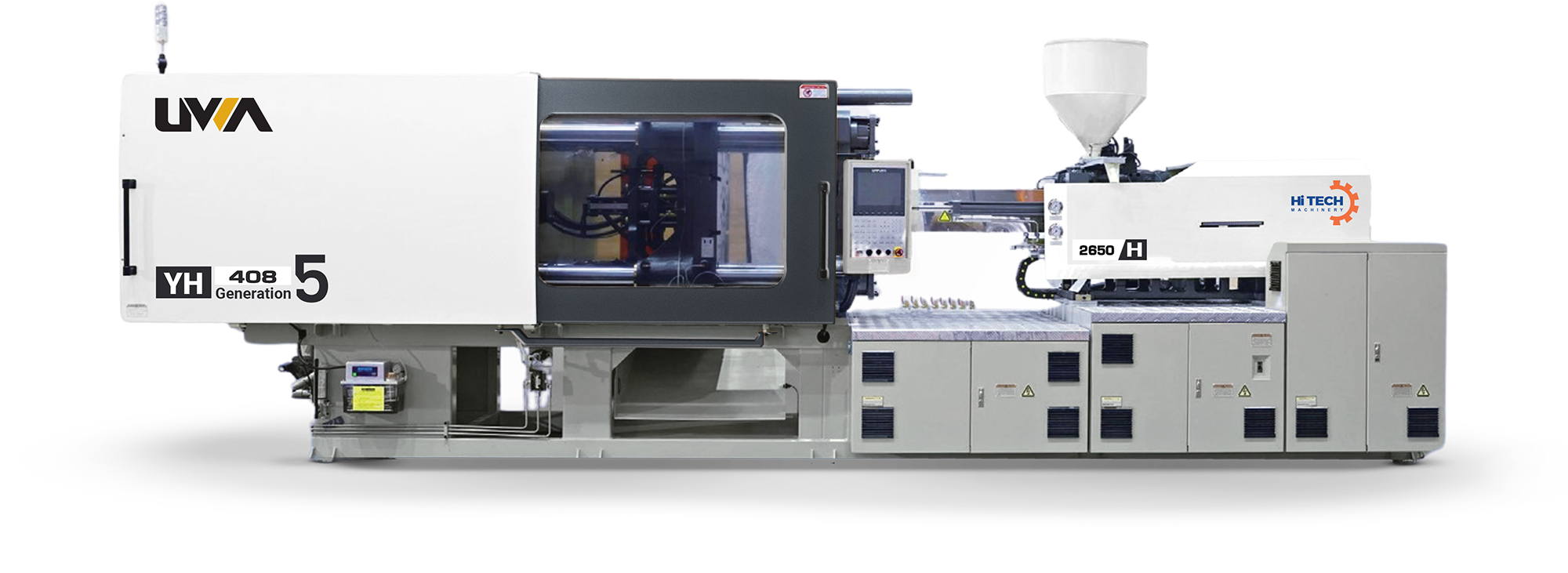

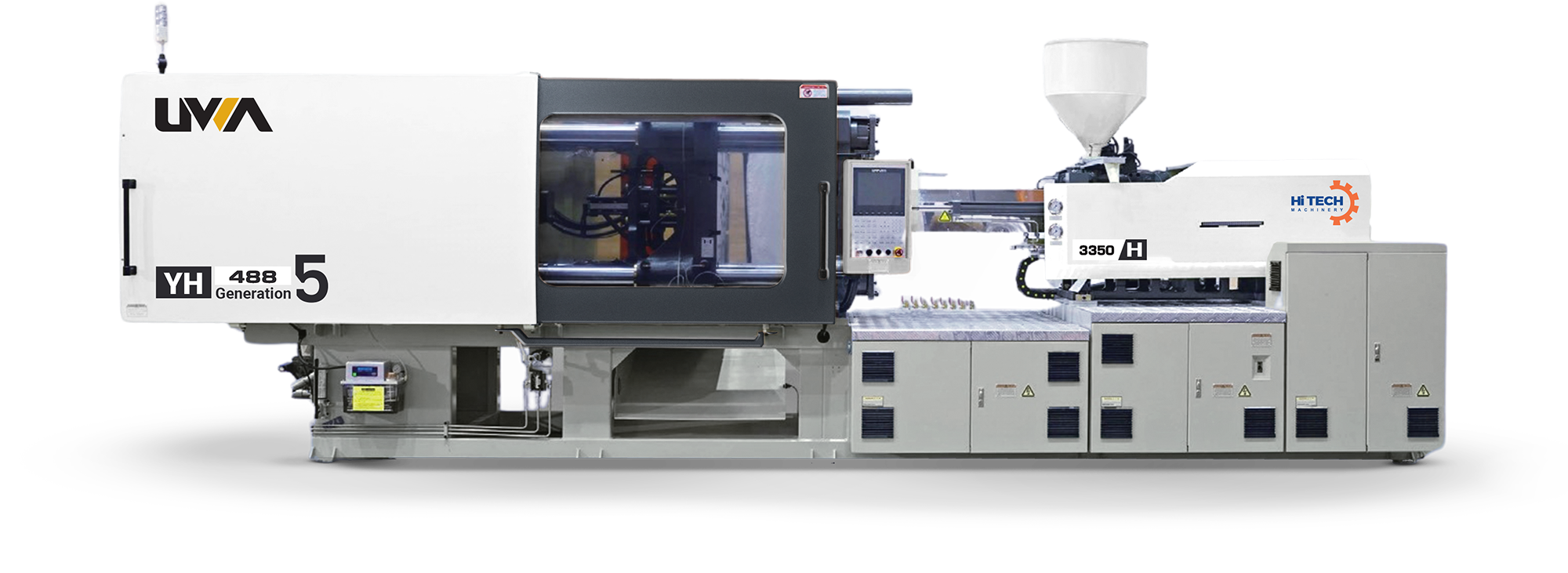

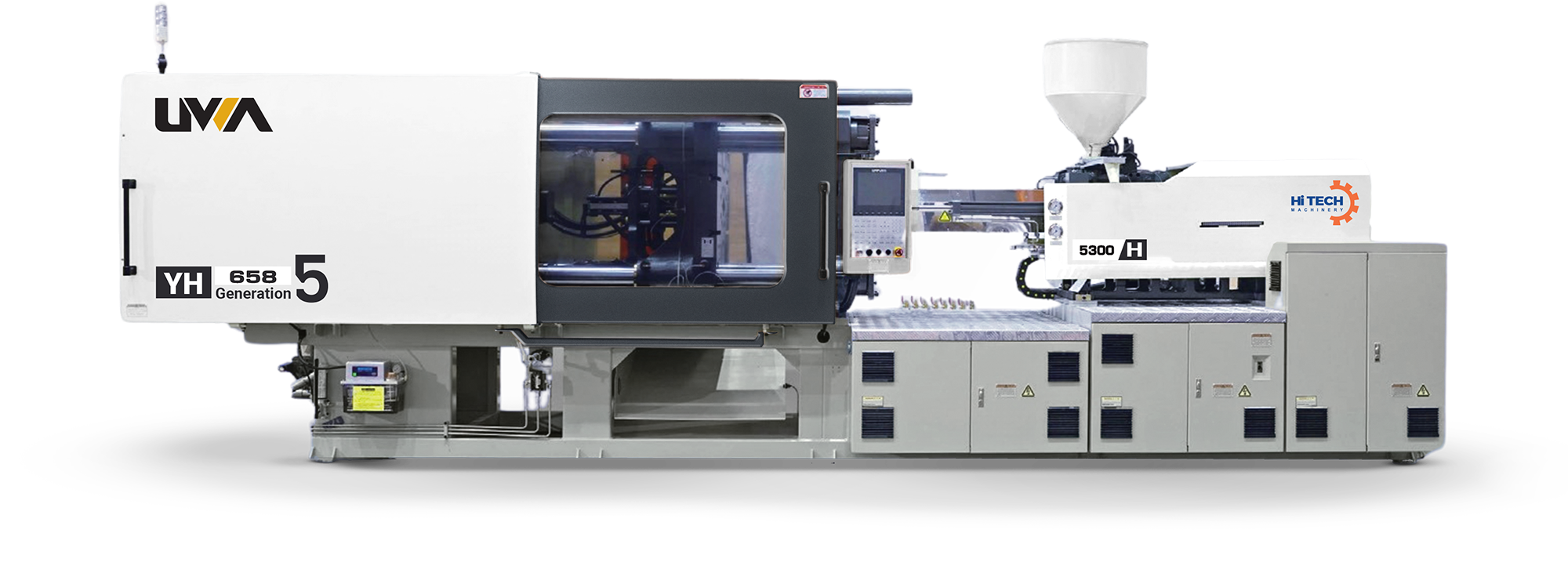

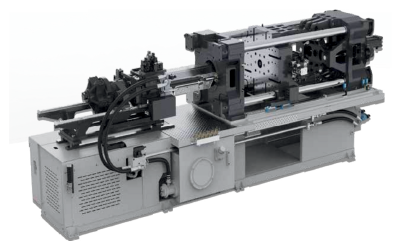

Exploring innovative technologies, interdisciplinary collaboration, and unconventional methods can lead to breakthroughs in manufacturing plastic shopping baskets through plastic basket making machines. We have many models ranging from YH 308 Ton to YH 658 Ton.

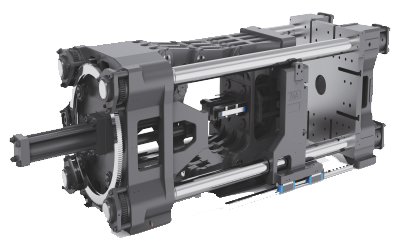

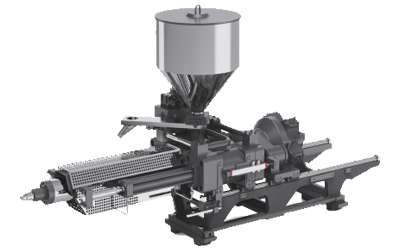

Ningbo Yonghua Plastic Manufacturing Co., Ltd. UWA, established in 1985, is a leading national high-tech enterprise specializing in plastics molding machine manufacturers. Accurate mold alignment is ensured by the clamping unit, and high-response wireless communication is provided by the YongHua Cloud control unit. Plastic is melted and injected by the injection unit, which uses pressurized oil to run the hydraulic unit efficiently.