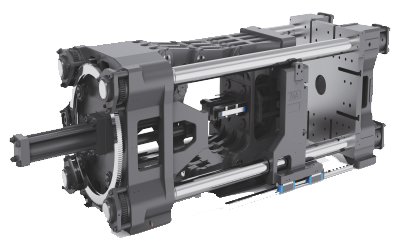

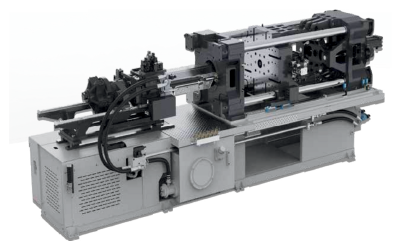

Exploring alternative solutions like innovative technologies, such as clamping force in injection molding, and fostering cross-disciplinary collaboration can lead to breakthroughs. Two Platen Injection Molding Machines offer precision and efficiency, revolutionizing plastic molding machines. These advancements unlock new possibilities for sustainable and accurate production. We have many models ranging from YU 1080 Ton to YU 2500 Ton.

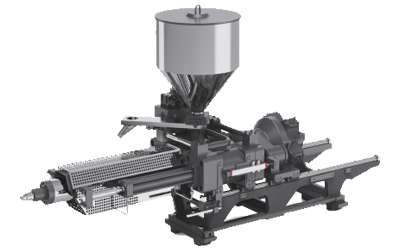

Ningbo Yonghua Plastic Manufacturing Co., Ltd. UWA, established in 1985, is a leading national high-tech enterprise specializing in plastics molding machine manufacturers. The clamping unit ensures accurate mold alignment, and the YongHua Cloud control unit offers high-response wireless communication. The injection unit melts and injects plastic, using pressurized oil to power the hydraulic unit efficiently.