PET PREFORM

ADVANCE PET PROCESSING

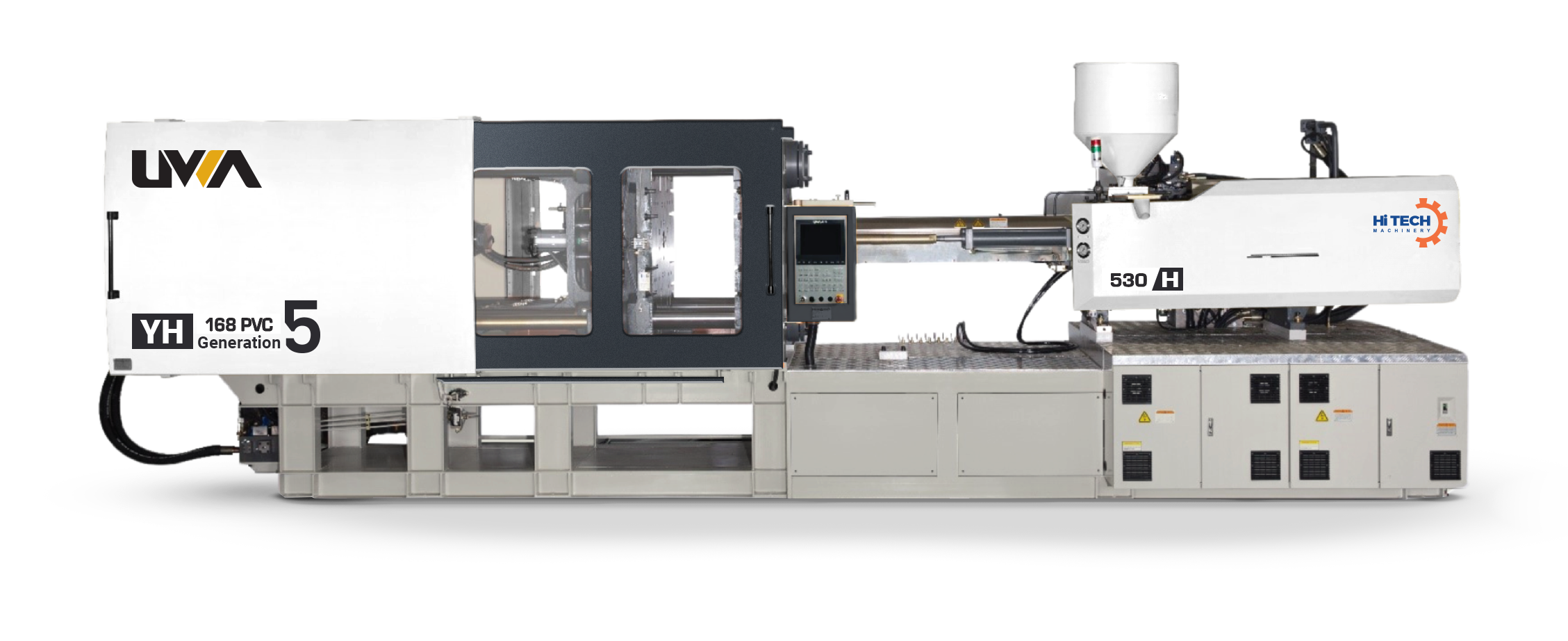

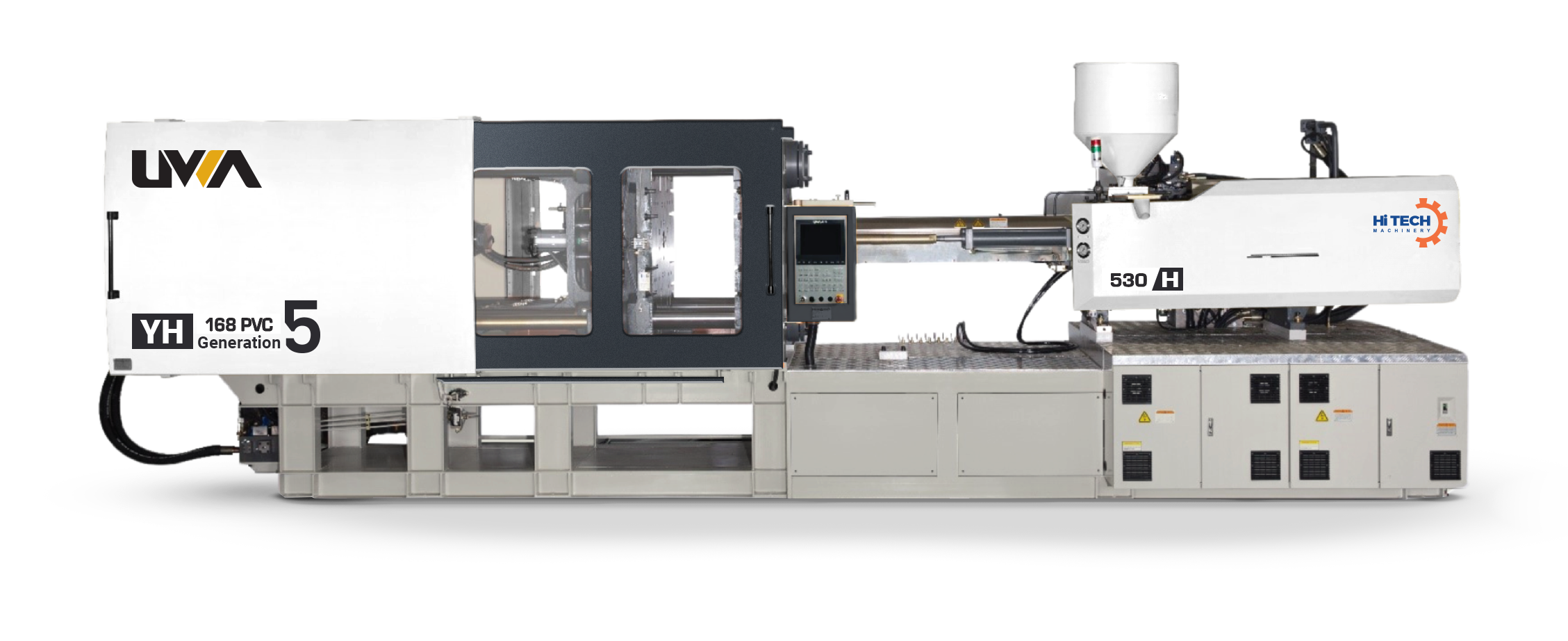

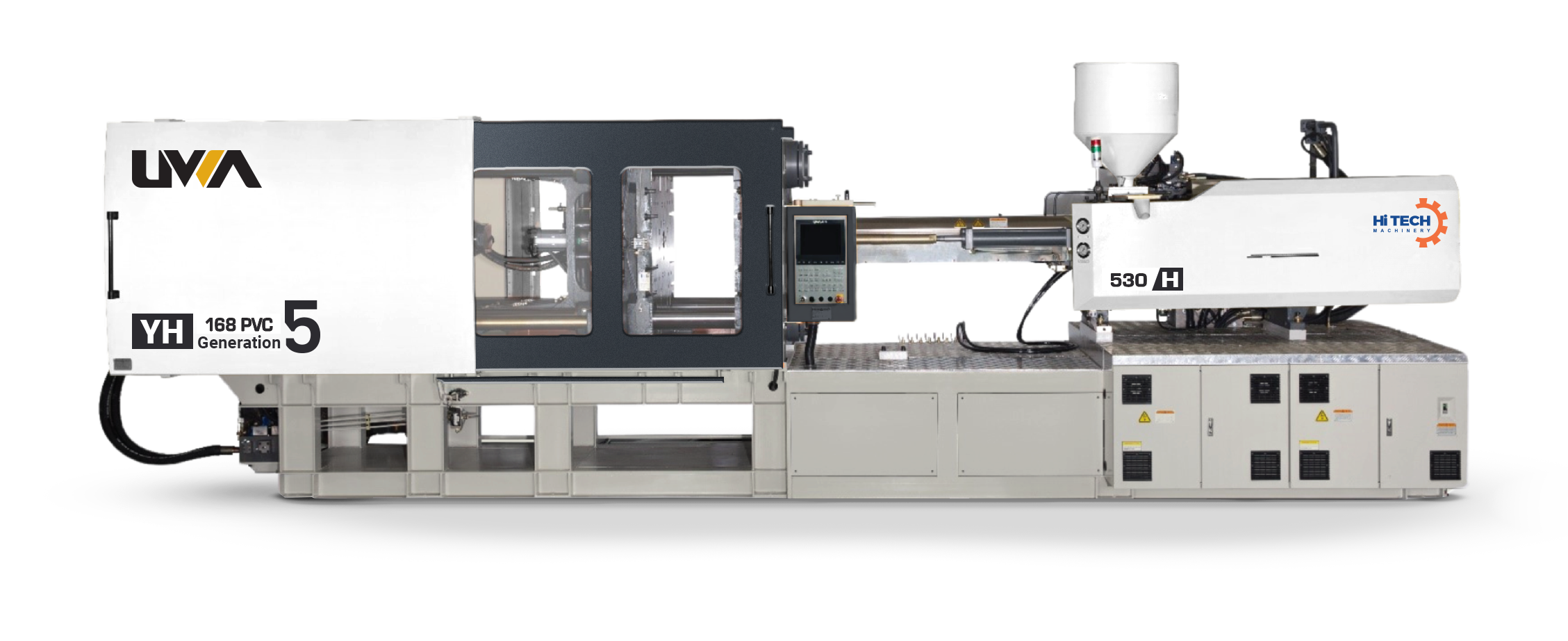

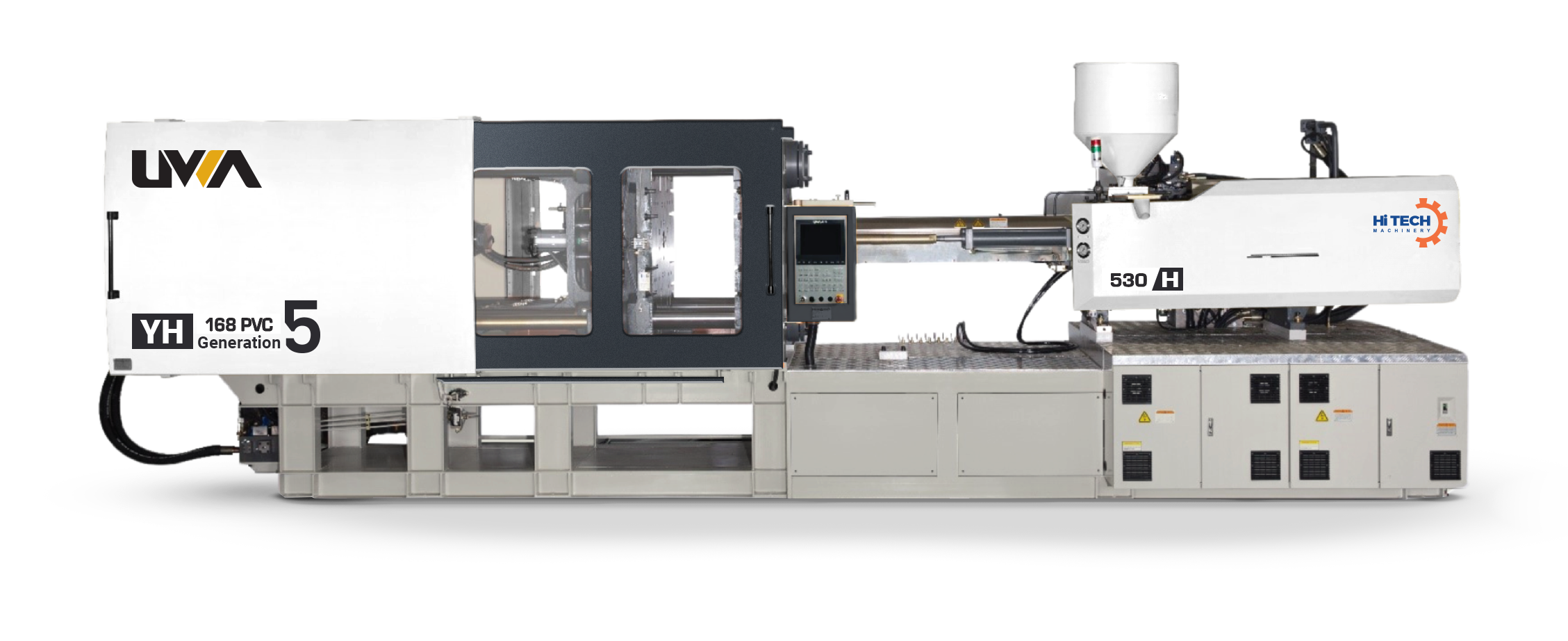

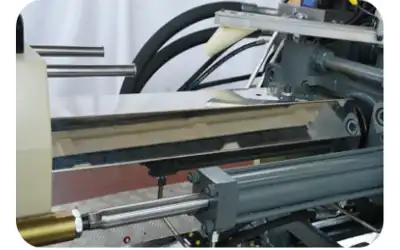

UWA YH 5 generation Series Pet standard and Pet preform machine special Injection Molding Machine is a specialized plastic bottle making machine designed for high-quality PET preform processing. It is equipped with a special screw and barrel for improved plasticizing, a servo motor control system for energy efficiency, and an enlarged motor and pump for increased speed and output.

PET preform machine (Polyethylene Terephthalate) is a thermoplastic polymer that is widely used in the production of various products, including PET preforms for injection molding. Some common applications of PET preforms include:

- Beverage Industry

- Food Packaging

- Personal Care Products

Download Brochure

Explore unique offerings and elevate your experience.

ALL PRODUCTS

Latest Machinery Innovations

Exploring innovative technologies, interdisciplinary collaboration, and unconventional methods can lead to breakthroughs in manufacturing plastic bottle making machine, plastic bottle manufacturing machine, and PET preform machine. Models range from YH 158 Ton to YH 488 Ton.

YH 168-T-620H Gen5 PET

YH 188-T-620H Gen5 PET

YH 188-T-850H Gen5 PET

YH 228-T-850H Gen5 PET

YH 228-T-1300H Gen5 PET

YH 288-T-1300H Gen5 PET

YH 288-T-1450H Gen5 PET

YH 308-T-1450H Gen5 PET

YH 308-T-1800H Gen5 PET

YH 358-T1800H Gen5 PET

YH 358-T-2700H Gen5 PET

YH 358-T-2700H Gen5 PET

OUR APPLICATIONS

Looking For Injection Molding

ADVANCED TECH

Trustworthy Products

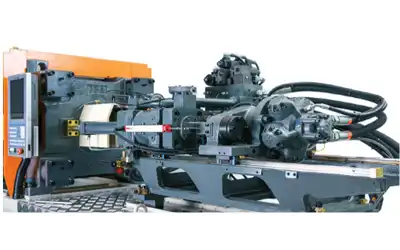

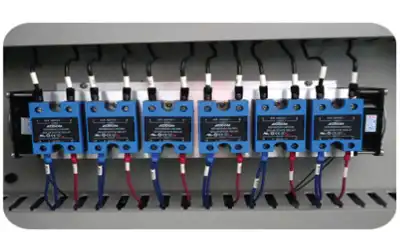

Ningbo Yonghua Plastic Manufacturing Co., Ltd. UWA, established in 1985, is a leading national high-tech enterprise specializing in plastics molding machine manufacturers. Our machine features optimized template designs and oversized ejection cylinders for PET bottle molds, with high-performance control systems and efficient hydraulic mechanisms for precise and fast production.

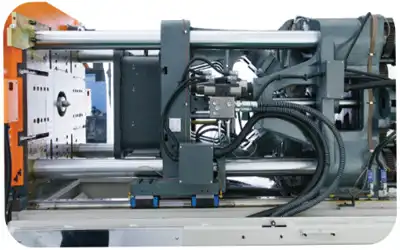

The System Pressure is raised to 17.5MPA. Non-Welding Technology of main power piper. New graphite self-lubricating steel sleeve.

Full-spread pattern aluminum plate for machine frame. Non-welding technology for power pipe ·New graphite steel sleeve. Mid-position holding for ejection.

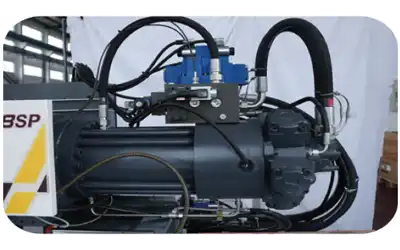

UWA YH-Series is equipped with a special screw and barrel for improved plasticizing, a servo motor, and an enlarged motor and pump for increased speed and output.

YH-Series Rigid PVC Machine is a specialized machine designed for processing PVC materials. It is equipped latest technology servo motor, saving up to 40-60% of energy.

Chlorinated Poly Vinyl Chloride, is a highly versatile thermoplastic material used in the production of molded PVC products specifically designed for construction fittings.

New high-rigidity clamping, bilinear guide rail, and single-cylinder injection for stability. Optional speeds of 230mm/s or 330mm/s.

Efficient injection, synchronized mold control, durable design, and enhanced motor for recycling. Cost-effective for small entrepreneurs.

All-electric injection molding machine with advanced servo control for efficiency. Ideal for diverse industries, offering precision, energy efficiency, and environmental friendliness.

Reliable, precise, and eco-friendly injection molding machine with high-speed operation for better product quality.

Efficient two-platen machine for large plastic parts, ideal for automotive and consumer goods. Advanced injection molding tech.