PACKAGING SOLUTION

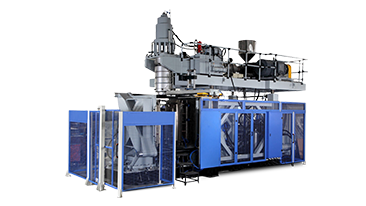

HiTech Machinery is a professional OEM manufacturer of extrusion blow molding machine equipment based in China, serving the Middle East. Over the years, we have effectively integrated advanced technology and theories from both domestic and international sources.

Our primary focus is on designing, manufacturing, and selling a diverse range of fully automatic bottle-making machines and fully automatic extrusion blow molding machines. We offer a comprehensive selection with 4 wide series and over 40 different models.

HiTech plastic machinery is capable of producing plastic bottles, drums, cans, containers, toolboxes, oil tanks, plastic pallets, and special-shaped auto parts ranging from 5ml to 1000L. We work with various materials such as PE, PP, PVC, PETG, PS, EVA, PVDC, ABS, TPE, TPU, and more.

Our high-quality, reliable extrusion machines are top sellers in over twenty provinces and are exported to Southeast Asia, the Middle East, Middle Asia, and South Africa. Clients consistently praise our machines and services.

Extrusion blow molding machines, essential for producing hollow plastic products like bottles, containers, and tanks, rely on a continuous extrusion process. To keep these machines running at peak performance, regular maintenance is imperative. Our services are designed to support the unique needs of extrusion blow molding equipment, ensuring consistent production quality and reducing the risk of unexpected failures.

Plastic extrusion blow molding machine technology can create hollow plastic products in various sizes, shapes, and colors for a range of industries. Whether it’s packaging for beverages, personal care items, or transportation of liquids and chemicals, Extrusion blow molding machinery offers a versatile and cost-effective solution for plastic product manufacturing machines.

HT-A Series Extrusion

Blow Molding Machine

HT-H Series Extrusion

Blow Molding Machine

HT-BA Series Extrusion

Blow Molding Machine

HT-B Series Extrusion

Blow Molding Machine

Welcome to “Machine Demonstration,” our exclusive video series where we examine teamwork, innovation, and industry knowledge in the plastic molding machine sector. Come see how leading companies like JOBO, Shangair, UWA, Huara, and Jinhu in the field are showcasing their innovative technologies and seamless solutions. Discover the manufacturing industry’s future through firsthand accounts and behind-the-scenes insights that will keep you at the forefront of this ever-evolving industry.