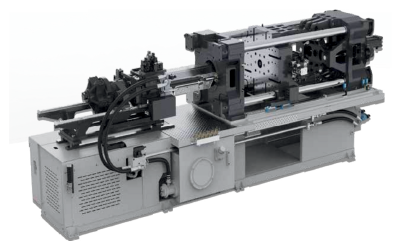

At HiTech Machinery, we are committed to offering our clients worldwide the newest developments in plastic manufacturing machines. Our dedication to efficiency and quality is demonstrated by our cutting-edge NEW 5 Generation YHS Series is available from 128 Ton to 268 Ton, and has a thicker tie rod diameter for improved stability and durability. We assist firms in increasing the quality of their products, minimizing waste, and maintaining their competitiveness by using state-of-the-art technologies and encouraging teamwork. See how our plastic injection molding machine may improve your manufacturing capacities and propel your company forward by pursuing our extensive product selection.

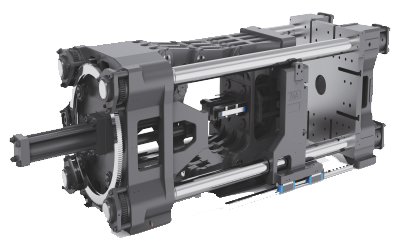

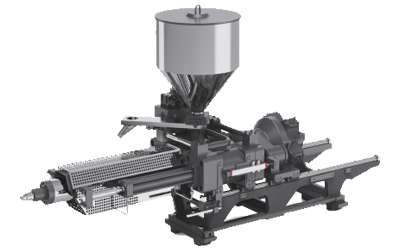

Our advanced plastic manufacturing machines combine modern technology with dependable performance to meet the demands of enterprises throughout the world. Some of the crucial components are the YongHua Cloud control unit for efficient wireless communication with rapid response times, an injection unit for efficient plastic melting and molding, a clamping unit with precise toggle, and a hydraulic unit with pressurized oil for seamless machine operation. Together, these elements provide precision, efficiency, and exceptional results in every manufacturing process.