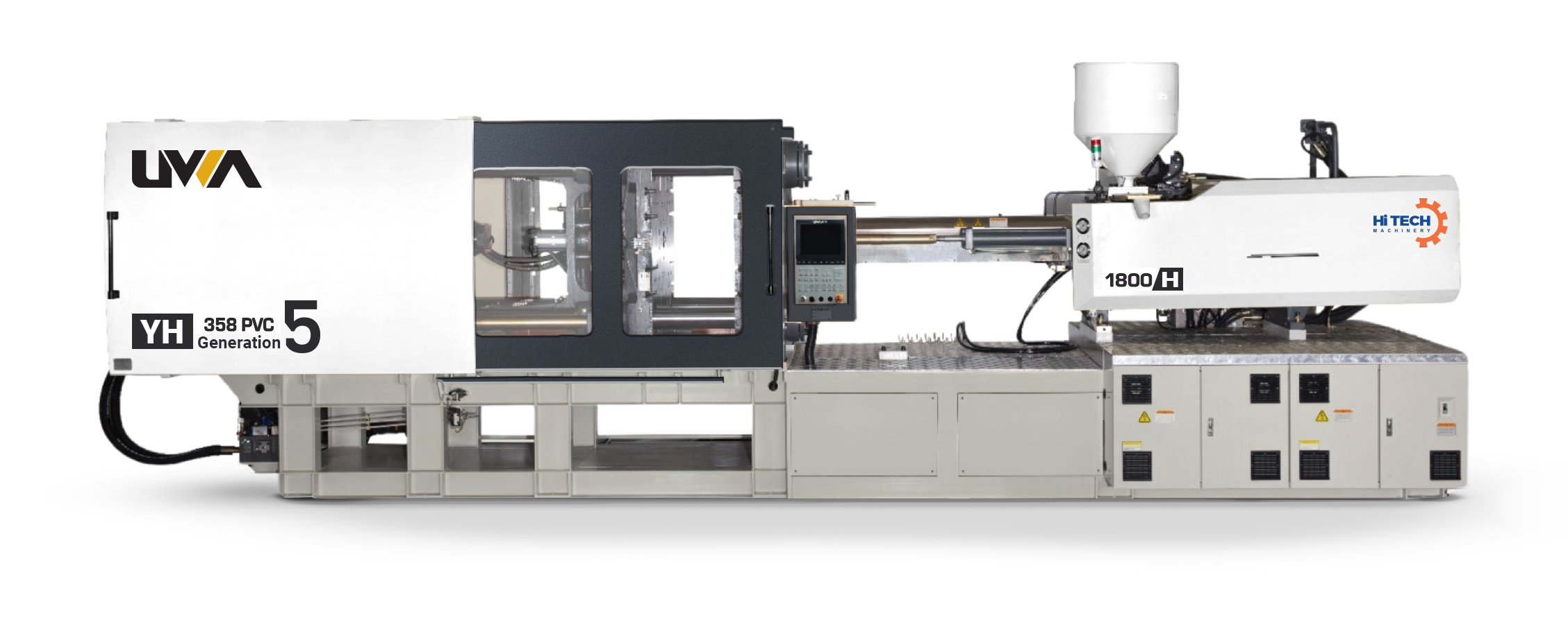

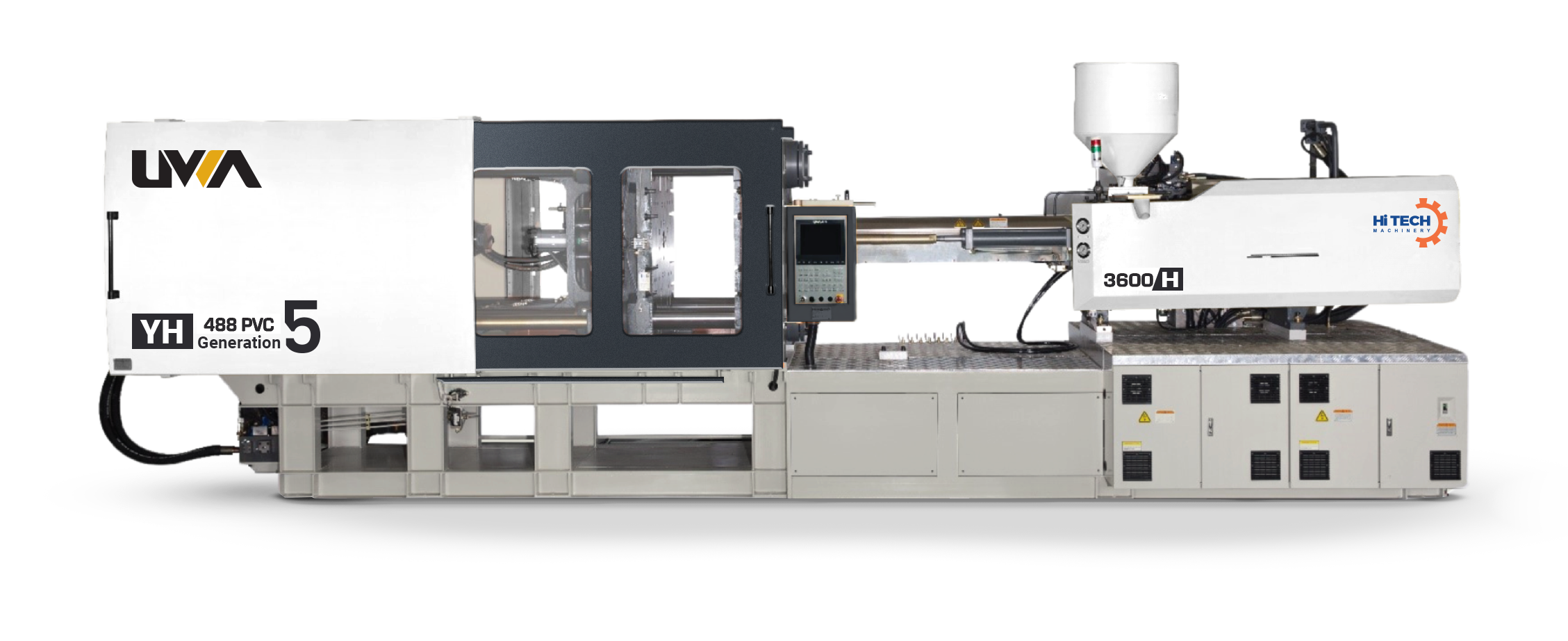

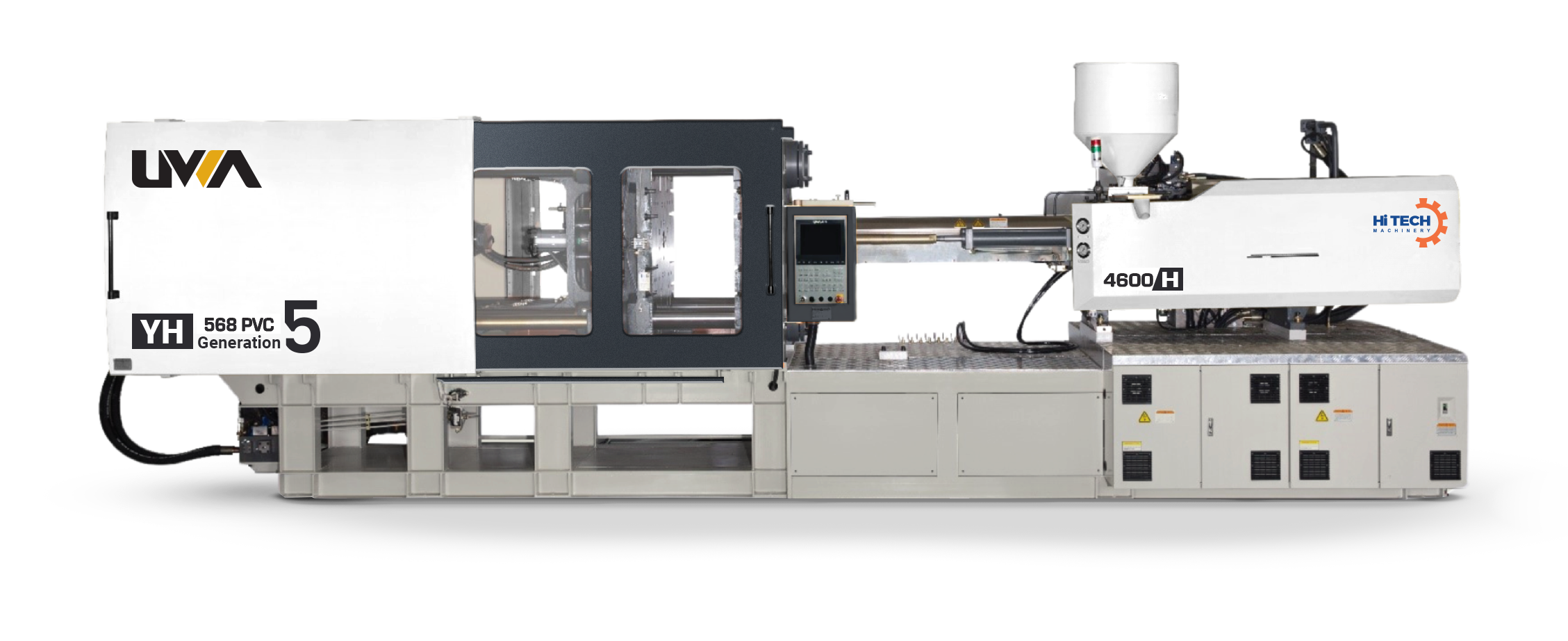

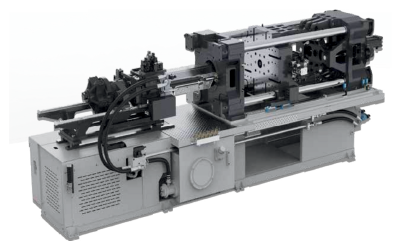

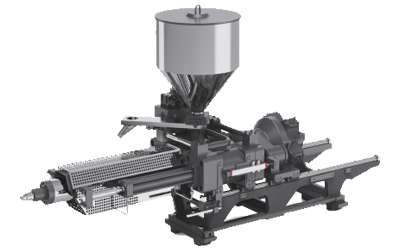

Considering alternative solutions, such as innovative technologies, interdisciplinary collaboration, and unconventional methods, can open new avenues for problem-solving and lead to breakthroughs in manufacturing PVC pipe fittings, PVC pipe and fittings, and PVC pipe making machines. The models available include YH 308 Ton to YH 968 Ton.

Are you looking for PVC pipe fittings, plastic water pipe fittings, and PVC pipe manufacturing machines through injection molding solutions? We provide great precision and efficiency for all your manufacturing demands with our sophisticated models, which range from YH 308 Ton to YH 968 Ton. You can depend on our technology to deliver dependable and high-quality results.

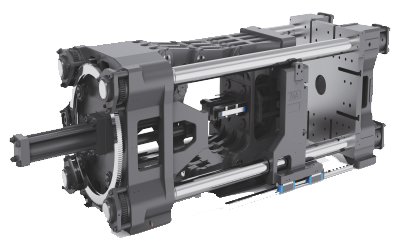

Ningbo Yonghua Plastic Manufacturing Co., Ltd., UWA established in 1985, is a leading national high-tech enterprise specializing in plastics molding machine manufacturers. The clamping unit ensures precise mold alignment, and the YongHua Cloud control unit provides high-response wireless communication. The injection unit melts and injects plastic, while the hydraulic unit uses pressurized oil for efficient operation.