HiTech Machinery is the exclusive partner and sole distributor of Jinhu Group, specializing in promoting and selling pipe profile and sheet board extrusion equipment for manufacturing plastic pipes and sheet board materials.

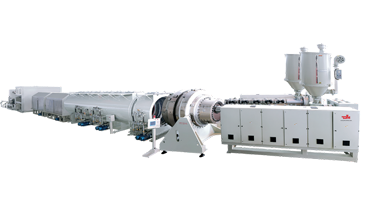

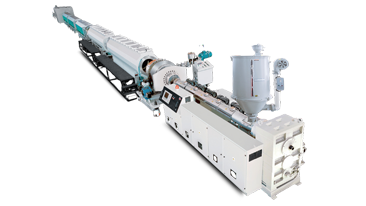

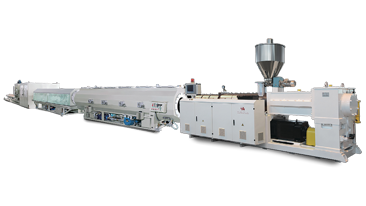

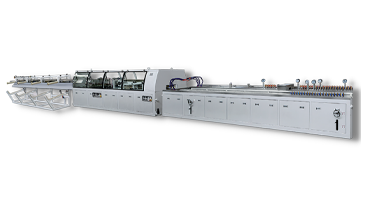

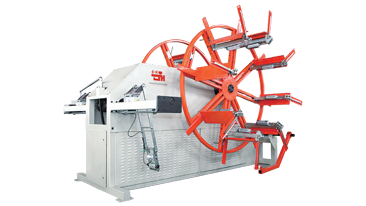

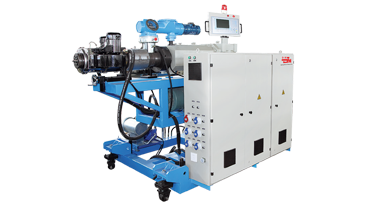

Jinhu Group, with over 33 years of experience in plastic machinery, has established five production bases in Shanghai and Zhejiang. They offer a wide range of products, including plastic pipe production lines, profiled production lines, and plastic board and film production lines, as well as single screw extruder and double screw extruders, screw and barrels for plastic machinery, and other related equipment.

JINHU strives to serve society with high-quality, innovative, and energy-efficient products.

This section features a selection of awards and diplomas given out in celebration of remarkable achievements in the plastic machinery industry. These honors highlight exceptional accomplishments and knowledge in plastic molding machines and extrusion equipment.

The plastic industry encompasses the production of plastic extrusion machine pipes, profiles, and recycling equipment. Plastic extrusion pipes are widely used for water supply, UPVC drainage pipes, and industrial applications due to their energy efficiency and corrosion resistance. Plastic extrusion profiles are used in window frames and handrails, with additives enhancing their properties. The recycling industry processes waste plastics into new products, reducing environmental impact. Pelletizers are essential for melting and condensing materials for recycling, contributing to resource conservation.

Plastic pipes are essential in modern construction due to their superior performance, health benefits, and cost-effectiveness. They include UPVC drainage pipes, UPVC pipes, aluminum-plastic composite pipes, PE pipes, and PPR hot water pipes. Compared to traditional pipes, plastic pipes offer energy savings, environmental protection, high strength, and corrosion resistance. They have smooth inner walls, reducing scaling and making installation and maintenance easy. Plastic pipes machinery are used in building water supply, drainage, urban infrastructure, gas and electricity conduits, industrial fluid transportation, agricultural irrigation, and municipal, industrial, and agricultural fields. HiTech Machinery promotes high-quality plastic pipes profile for their durability, efficiency, and environmental friendliness.

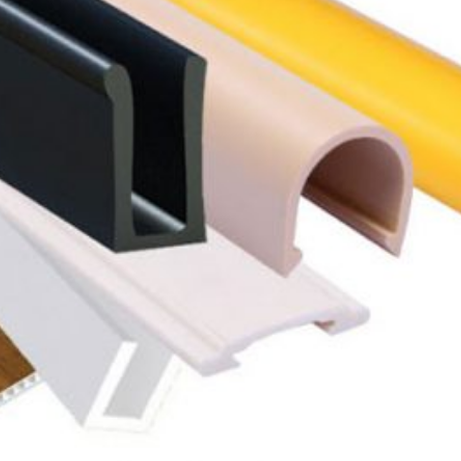

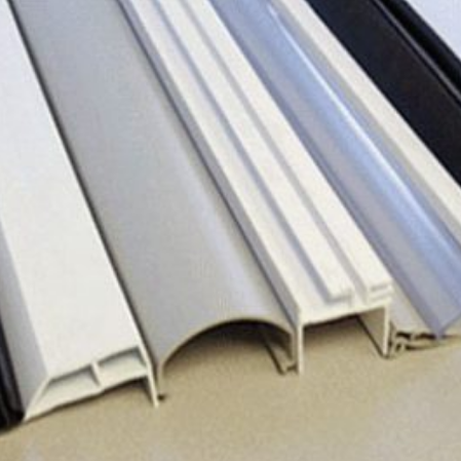

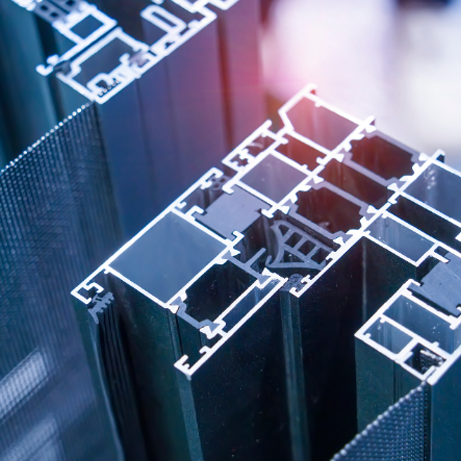

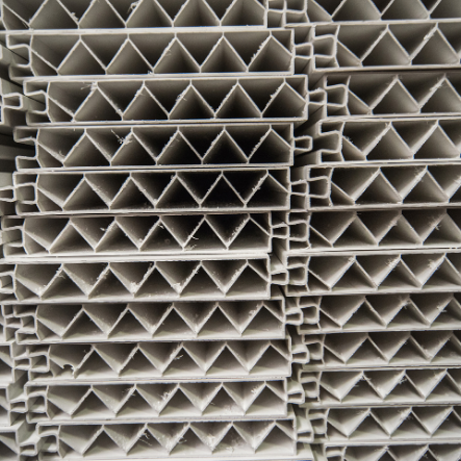

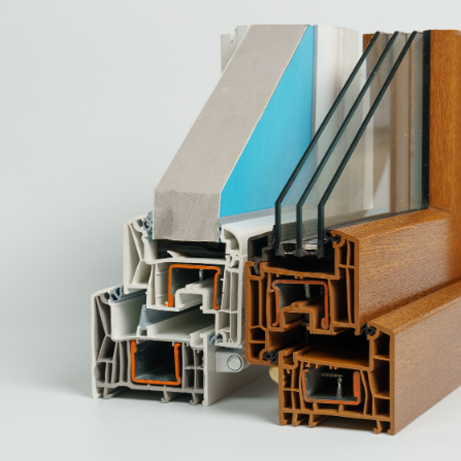

Plastic profiles, like window frames, stair handrails, and baseboards, are widely used. They are made from hard PVC, semi-hard PVC, soft PVC, polyurethane foam, and other materials. To improve impact strength, additives like CPE, EVA, ACR, and MBS are used, typically in amounts of 6% to 10%. MBS is used in transparent profiles, EVA should avoid lead stabilizers, and CPE should not be mixed with zinc stabilizers. HiTech Machinery offers a range of plastic profile products with these considerations in mind.

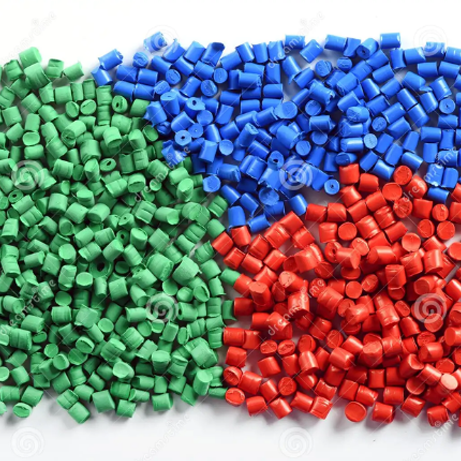

As plastic consumption rises, so does plastic waste, including films, wires, fabrics, foams, packaging, and daily-use products. After sorting and processing, waste plastics recycling are crushed, granulated, and modified into various particles, ready for recycling into new products. HiTech Machinery plays a role in this recycling process with its range of equipment and solutions.

The plastic recycling granulator is a machine that transforms waste plastics into specific shapes, suitable for materials with a melting point (softening point) below 300°C. This includes sulfur, paraffin wax, rosin, asphalt, stearic acid, and various resin products. It is also used for recycling additives, rubber, and plastic products. HiTech Machinery offers this granulator as part of its range of recycling solutions.

There is something for everyone in our model range, which includes the JHE45, 60, 75, 90, 105, and 120 Ton. These models offer various options that fit different needs and preferences at HiTech Plastics.

We have a wide range of models, including the SJP 75, 93, 114, and 135 Ton, which provide a variety of choices to suit different requirements of plastic pipe machinery.

Single and double-outlet screw extruders come in a variety of models, such as 16, 32, 75, 110, 315, 450, 630, 710, 1000, and 1400 Tons, offering a wealth of options to meet various needs and preferences.

From 16-63, 75-160, and 110-250 Ton, there is a model in our portfolio that will suit every need. They are thoughtfully designed to satisfy a variety of needs and preferences.

Our model range, which includes the SJZ 65, SJZ 80, SJZ 92, and SJZ 110, offers a wide range of options for single, double, and four outlets, each of which is designed to satisfy a different set of demands and preferences.

Models of PVC extrusion machines include SJZ55, SJZ65, SJZ80, and SJZ92. Ton makes sure there is something for everyone by providing a wide range of solutions that are suited to suit different needs and interests at Hitech Machinery.

The best models of PVC extrusion machines include SJZ55, SJZ65, SJZ80, and SJZ92. Ton makes sure there is something for everyone by providing a wide range of solutions.

The FZD 63, FZD 110, FZD 160, FZD 250, FZD 400, FZD 630, and FZD 800 Ton PVC vacuum model line provides a wide range of configurations designed to satisfy different needs and tastes, making sure there's something for everyone at HiTech machinery.

The PE vacuum models line, which includes the STV 63, STV 125, STV 250, STV 630, STV 800, STV 1000, STV 1200, STV 1400, STV 1600, and STV 2000 Ton, offers something for everyone. These models are made to meet a variety of needs and preferences.

With a choice of models to choose from, including the QY 63P, QY 160L, QY 250L, QY 450L, and QY 630L, haul-off units offer a variety of alternatives to suit a wide range of needs and tastes at HiTech Machinery.

The cutter unit model range, which includes the SPS-32, SPS-63, and SPS-110 single and double stations, provides a wide range of choices designed to accommodate different requirements and tastes, so there is something for everyone at HiTech Machinery.

With a variety of options to suit varying needs and preferences, the 32, 63, 110, 125, and 250 Ton versions of All Off Machines have something to offer everyone at HiTech plastic.

With models including YG240S, YF240A, YF 300A, YG 600, YG 900, and YG 1200 Ton, Haul Off Cutting Units offers a wide range of choices to suit different needs and tastes, so there's something for everyone at HiTech plastic machinery.

The range of single extruder models includes JH20, JH25, JH30, JH35, JH45, JH50, JH50, and SJZ45. Ton makes sure there's something for everyone by providing a wide range of solutions that are suited to suit different needs and interests at available HiTech plastic.

Our demonstration showcases the precision and efficiency of our plastic extrusion machine equipment, producing high-quality plastic pipe extrusion machines that meet industry standards. Witness firsthand the advanced technology and expert craftsmanship that make Jinhu a leader in plastic machinery.