High Tech high-speed injection moulding machine has been constantly developed and improved for decade’s years according to the constant topic – less weight of plastic parts. The High Tech-HH series applications are including thin-wall containers, ice cream containers, lunch boxes, bowls, spoons and forks, caps, preforms, medical parts and etc., that thanks to it having nice success in safety, high injection speed, high precision, high energy saving and high stable running.

High Tech High Speed Injection Machine Highlights

1. High Speed

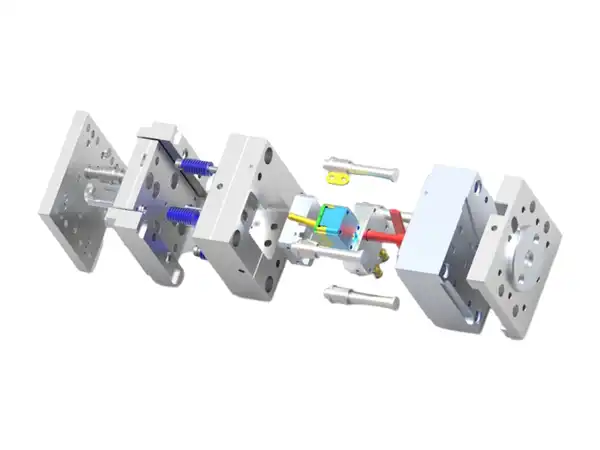

High Tech high speed machine injection unit applies high precision single cylinder system with low inertia injection structure design for high injection speed and little vibration to guarantee stable production of quality less weight plastic parts.

2. High Energy Saving

There is quick-response servo system which could adjust the energy consumption according to the actual need, which could help save up to 70% energy compared with the traditional machine, and make the controlling more precision at the same time.

3. High Safety

Safe machine operation would be required more, hence, High Tech high speed machine applies triple protection – mechanical, hydraulic and electrical parts.

High Tech high speed injection moulding machine, hence, is pretty suitable for high precision parts or less weight parts, which could achieve short cycle time to meet the high production capacity requirement.

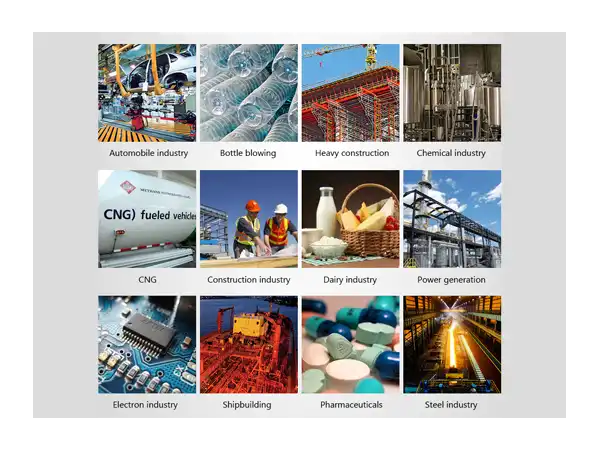

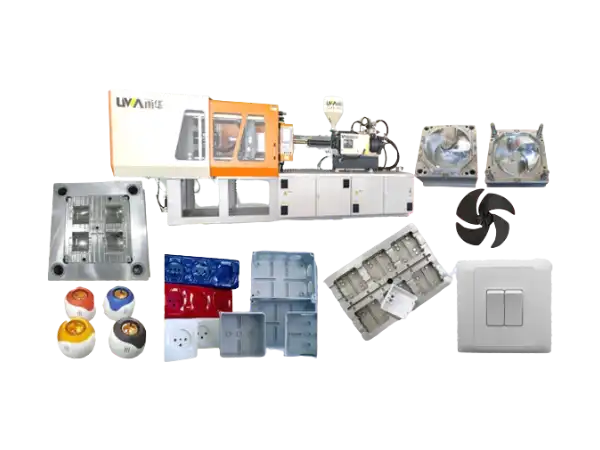

High Tech High Speed Machine Applications

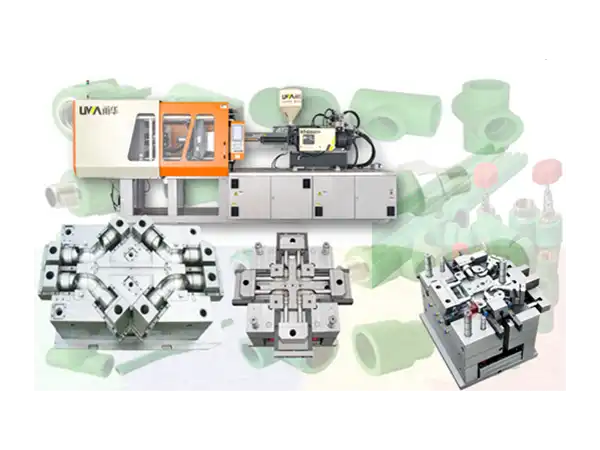

– Thin Wall Containers

560ml Thin Wall Container Production Line

*Stack Mould

* High Tech-400HH

* Cycle Time | 5 Seconds