AUXILIARY MACHINERY

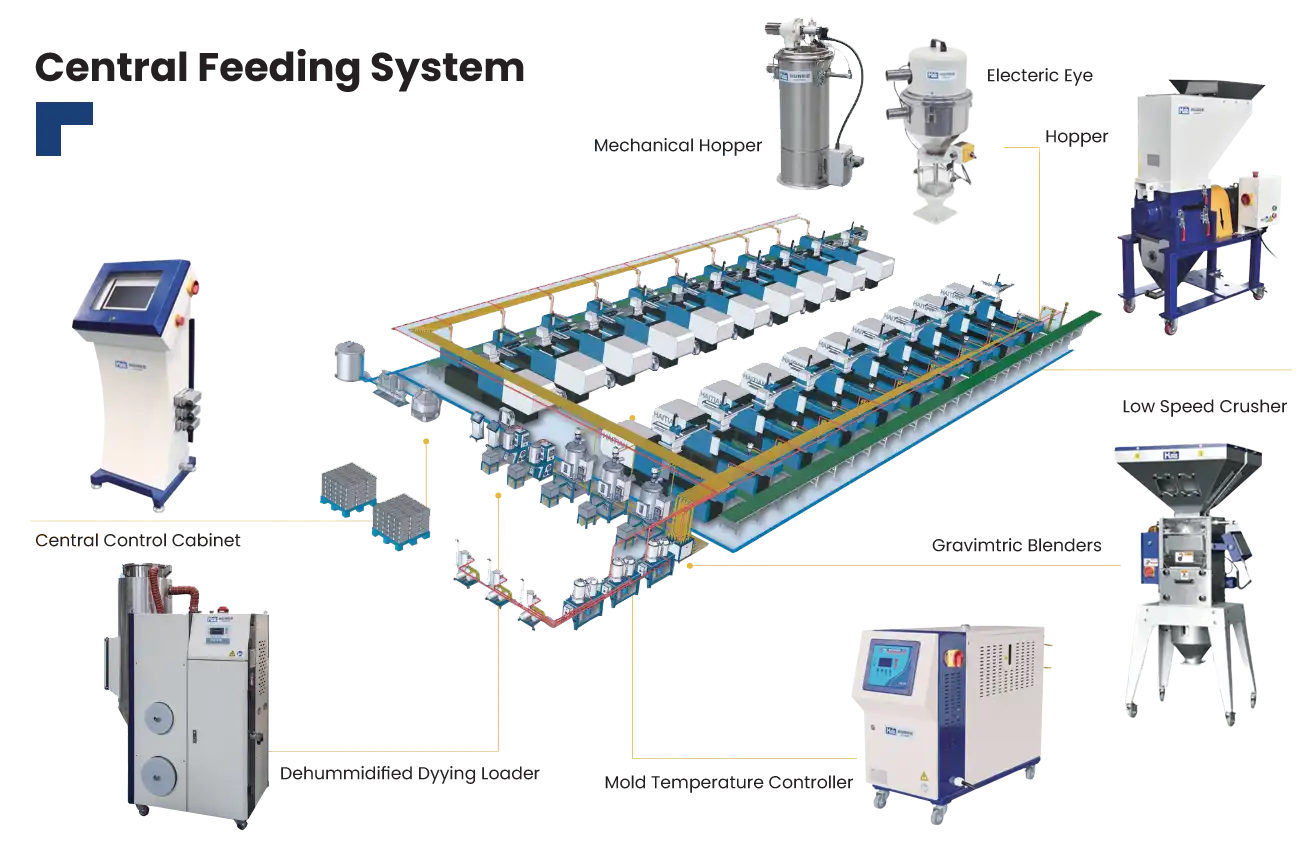

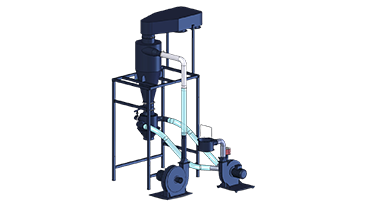

HUARE has created its brand and holds proprietary intellectual property rights. Additionally, the plastic rubber molding machine maintains a leading domestic status in granulating & shredding, mold temperature controlling, dehumidifying & drying, material loading & mixing, central feeding systems, central cooling systems, and more. All machinery is available at Hitech Machinery.

The company offers hundreds of products with specifications in over a dozen series and can provide professional system configuration schemes for individual customers.

HUARE is a leading enterprise in the domestic brand in the plastic rubber molding machine & rubber auxiliary machinery field. The company was the earliest to research and develop a professional manufacturer of plastic & rubber auxiliary machines and has been successful In the domestic and foreign markets for over twenty years.

HUARE integrates cutting-edge technology with COC ISO 9001-2015 and SGS CE certifications, ensuring meticulous product manufacturing under stringent quality controls for excellence in every aspect.

Next-Gen Solutions

Hopper Dryer

& Auto Loader

Industrial Chillers

& Temprature Controlers

Our Top Selling Products

HiTech Machinery is a leading supplier of top-quality plastic molding machines. Our extensive product line includes our best-selling hopper dryers, industrial color mixers, air & water cool chillers, screw type chillers, industrial chillers, and crushers. Each of these products is designed to meet the highest standards of efficiency and reliability, ensuring optimal performance for your plastic molding needs. Explore our innovative solutions and how we can help elevate your manufacturing processes.

In addition to possessing exclusive intellectual property rights, HUARE has established its brand. The company also continues to be the industry leader in the country in the following areas: central feeding systems, central cooling systems, material loading and mixing, mold temperature control, dehumidification and drying, and granulating and shredding. In addition to providing expert system configuration schemes for specific customers, the company sells over a dozen series containing hundreds of goods with varying specifications.

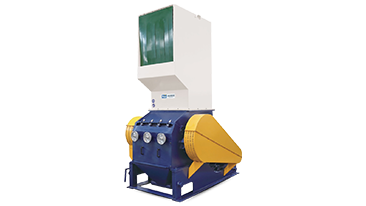

Industrial Granulators

Color Mixer

& Equipment

HUARE possesses exclusive intellectual property rights and has built its brand. Granulating and shredding, controlling mold temperature, dehumidifying and drying, loading and mixing materials, central feeding and cooling systems, and other related services are among the company’s leading offerings in the domestic market. HUARE is a plastic machinery specialist, offering over a dozen product series with hundreds of distinct specifications, including plastic molding machines and rubber sheet machines. To address each customer’s particular demands, we offer customized system setup options.