AUXILIARY MACHINERY

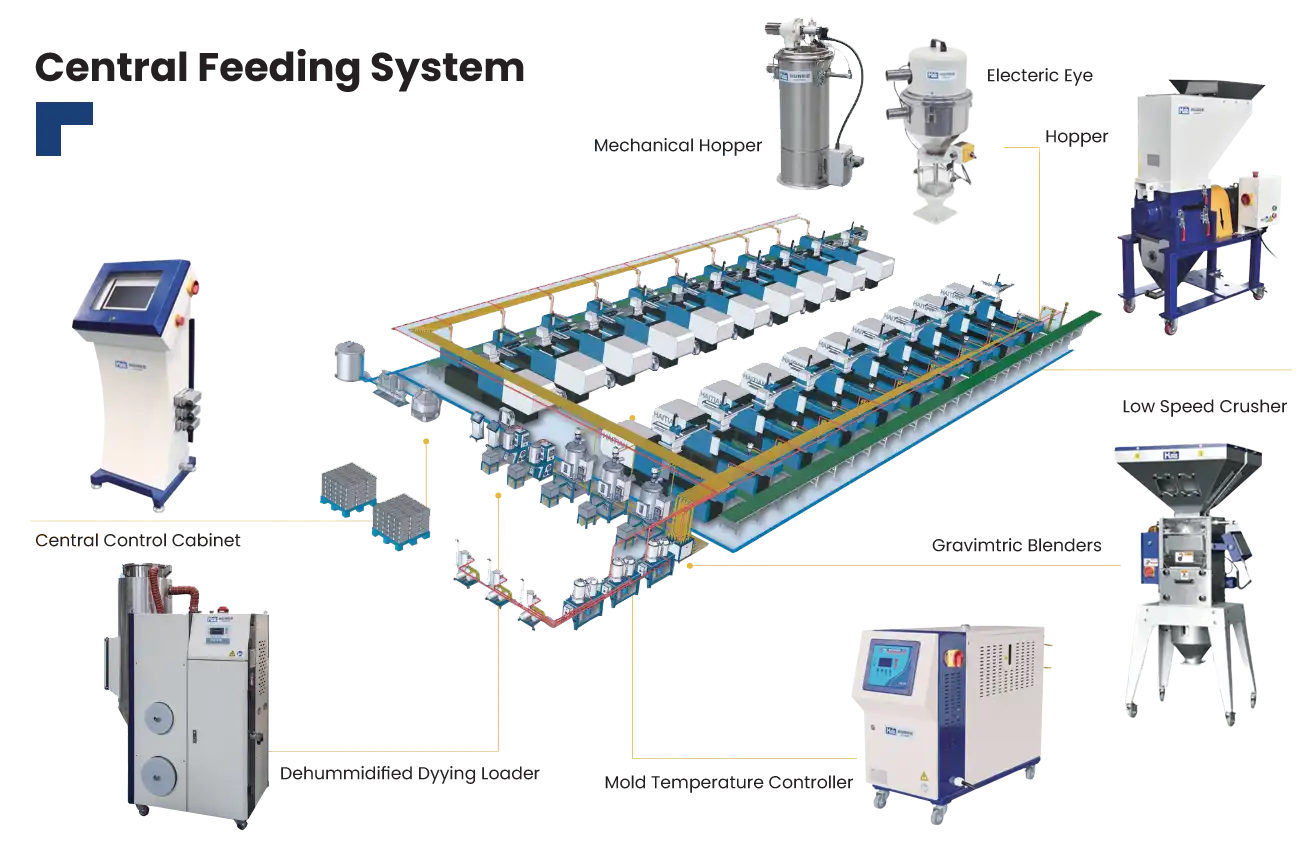

HUARE has created its brand and holds proprietary intellectual property rights. Additionally, the plastic rubber molding machine maintains a leading domestic status in granulating & shredding, mold temperature controlling, dehumidifying & drying, material loading & mixing, central feeding systems, central cooling systems, and more. All machinery is available at Hitech Machinery.

The company offers hundreds of products with specifications in over a dozen series and can provide professional system configuration schemes for individual customers.

HUARE is a leading enterprise in the domestic brand in the plastic rubber molding machine & rubber auxiliary machinery field. The company was the earliest to research and develop a professional manufacturer of plastic & rubber auxiliary machines and has been successful In the domestic and foreign markets for over twenty years.

HUARE integrates cutting-edge technology with COC ISO 9001-2015 and SGS CE certifications, ensuring meticulous product manufacturing under stringent quality controls for excellence in every aspect.

Next-Gen Solutions

Hopper Dryer

& Auto Loader

Industrial Chillers

& Temperature Controllers

Our Top Selling Products

HiTech Machinery is a leading supplier of top-quality plastic molding machines. Our extensive product line includes our best-selling hopper dryers, industrial color mixers, air & water cool chillers, screw type chillers, industrial chillers, and crushers. Each of these products is designed to meet the highest standards of efficiency and reliability, ensuring optimal performance for your plastic molding needs. Explore our innovative solutions and how we can help elevate your manufacturing processes.

In addition to possessing exclusive intellectual property rights, HUARE has established its brand. The company also continues to be the industry leader in the country in the following areas: central feeding systems, central cooling systems, material loading and mixing, mold temperature control, dehumidification and drying, and granulating and shredding. In addition to providing expert system configuration schemes for specific customers, the company sells over a dozen series containing hundreds of goods with varying specifications.

Industrial Granulators

Color Mixer

& Equipment

HUARE possesses exclusive intellectual property rights and has built its brand. Granulating and shredding, controlling mold temperature, dehumidifying and drying, loading and mixing materials, central feeding and cooling systems, and other related services are among the company’s leading offerings in the domestic market. HUARE is a plastic machinery specialist, offering over a dozen product series with hundreds of distinct specifications, including plastic molding machines and rubber sheet machines. To address each customer’s particular demands, we offer customized system setup options.

What types of auxiliary machine is available at HiTech Machinery?

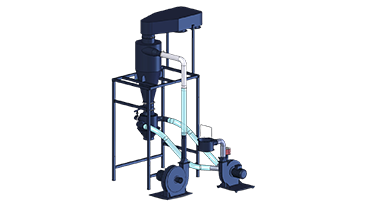

At HiTech Machinery, we offer all the supporting equipment used with injection molding machines, including those that manage material feeding, recycling, and drying (crushers, hopper dryers, auto loaders), mixing (color mixers, screw dosers), temperature control (industrial chillers, mold temperature controllers), and material conveying.

Why should I choose the material autoloader?

A vacuum autoloader automates the entire process of material feeding. Not only does it save time compared to manual feeding, but it also reduces material waste and contamination while keeping your production setup clean and efficient throughout the manufacturing cycle.

Can I get any customized auxiliary machinery?

Although we have a wide range of auxiliaries in different handling capacities to match various machine tonnages, there’s still an option to provide a custom solution.

What is the delivery time after placing the order?

Normally, we have a ready stock of injection molding machine auxiliaries, so you can receive them as soon as you place your order. However, for customized machines or those not currently in stock, delivery may take 60 to 90 days.

Do you provide installation and training support?

Yes. We provide complete installation support and operator training for all auxiliary equipment. Our technical team can either guide your staff remotely or visit your facility to ensure proper setup, operation, and maintenance of the machines.

Are these auxiliary optional or necessary?

Most auxiliary equipment is necessary for running a plastic injection molding setup. For instance, hopper dryers remove moisture from materials to prevent defects, crushers recycle scrap material, industrial chillers maintain machine and mold temperatures for quality parts, and auto loaders ensure a continuous material supply.

What Industrial chillers are available at HiTech Machinery?

We have different types of industrial chillers, including standard air-cooled and water-cooled models, as well as screw-type chillers in various cooling capacities ranging from 2 tons to 150+ tons to match your production requirements.

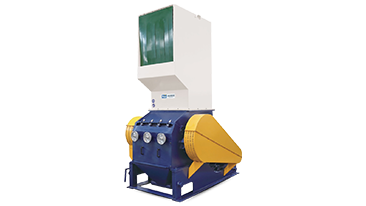

What is the difference between a plastic crusher and a granulator?

A plastic crusher breaks plastic scrap into larger, irregular pieces for easy handling, while a granulator cuts plastic into uniform, small granules suitable for direct recycling and reuse in production. In the local industry, these terms are often used interchangeably, as both devices serve the purpose of processing plastic waste.

Are spare parts easily available for your machines?

We maintain a stock of the most common replaceable spare parts and filters in our inventory. Even if a part isn’t available in-house, we can source and provide it to you within a reasonable timeframe.

Can the crusher/granulator handle any plastic material?

Yes. We offer different crusher series designed for various material types and sizes: HSS Series for bottles, cables, wires, caps, and profiles; HNS Series for preforms and profiles; HZS Series for oil drums, pipes, and turnover boxes; HTS Series for bulky items like bins, barrels, and chairs; HTP Series for pallets, sheet boards, and hollow profiles; and HSP Series for all types of pipes and corrugated materials.