Plastics have penetrated countless consumer industries, and healthcare is one of them. In this market, toothbrushes are the most obvious product; we have covered that as well.

But there’s another underrated product: dental floss. Apparently, it seems like a small item, but its market value is steadily growing. The cost of starting production is relatively low, demand is increasing, and the space isn’t yet overcrowded.

Read through this blog to learn what you need to begin your own dental floss manufacturing and how HiTech can support your manufacturing journey.

The Market Opportunity – Why Dental Floss?

According to Global Market Insights, the global dental care products market was valued at USD 56.8 billion in 2023 and is projected to grow beyond USD 101.4 billion in the coming years. Although toothbrushes currently dominate this space, dental floss also occupies a significant share.

Very High Local Demand

Looking at the local market, take Pakistan as an example, no local manufacturers currently produce dental floss; every unit is imported. In fact, in the year 2024–25 alone, Pakistan imported dental floss worth $368,000.

And that’s just one point in the supply chain. With growing awareness around oral hygiene and the recognition that flossing is far more effective, this demand is expected to keep rising.

Consumable Product

Another advantage is that dental floss is a consumable product – it needs more frequent replacement than toothbrushes. A single pack of 50 floss units, for example, can run out quickly for a household, driving repeat purchases.

Simple and Compact Setup

The manufacturing setup for dental floss is relatively simple, one injection machine (that too vertical) and a couple of auxiliaries, so the production space is comparatively very less compared to other plastic manufacturing setups.

How Dental Floss is Made?

Dental floss is essentially an injection molding product where plastic handles are molded around a strong filament, usually made of PTFE or nylon. The process starts with plastic granules, usually Polypropylene (PP) or HIPS (High Impact Polystyrene), being fed into a hopper dryer to remove any moisture.

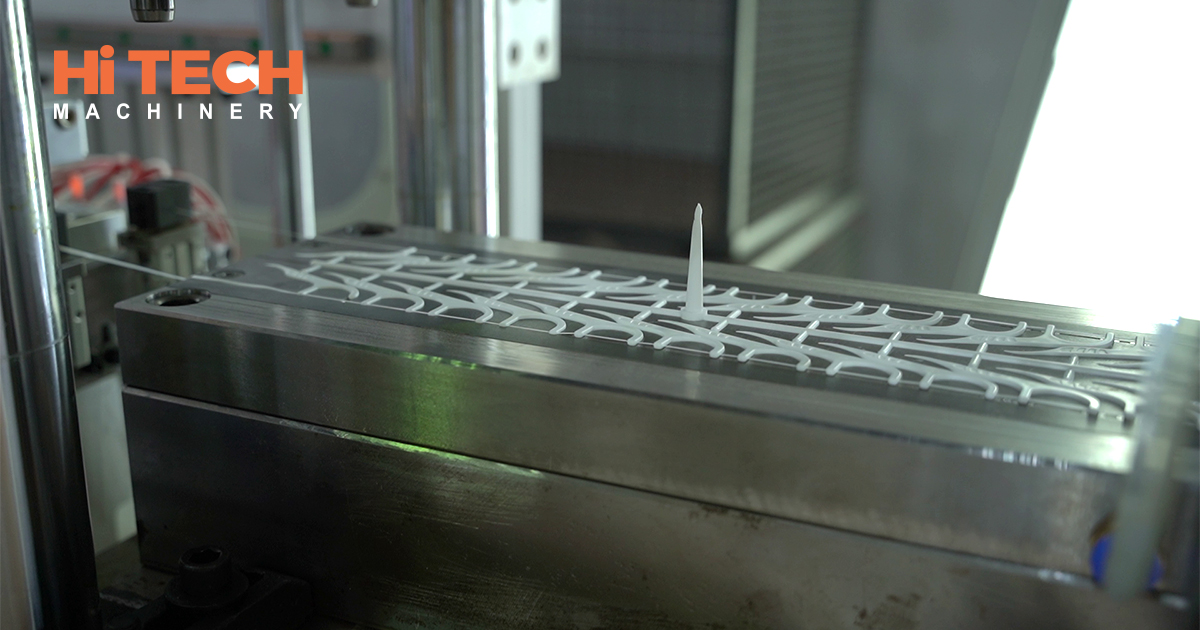

This material is then melted and injected into a multi-cavity mold. At the same time, the floss filament is carefully aligned within the mold so that each handle is formed with a piece of thread stretched across it.

Once the molding cycle is complete, the parts are ejected, excess filament is trimmed by melting, and the finished flossers are separated. Robotic arms handle the picking and stacking process to ensure speed and hygiene.

Machinery and Setup Required for Dental Floss

The production process already gives some idea of the setup, and HiTech offers a complete turnkey solution for dental floss manufacturing. The package includes:

Vertical Injection Molding Machine (40 Ton)

A compact yet powerful machine designed specifically for small products like dental floss, ensuring precision molding and efficient output.

Dental Floss Mold

Multi-cavity mold built to run efficiently with minimal cycle time.

Dental Floss Machine & Robotic System

A customized automation system that handles the product after molding, removes excess material, and neatly stacks the finished flossers for packing, reducing manual labor and ensuring hygiene.

Auxiliary Machines (Support Equipment)

Besides the injection machinery, the following auxiliary machines are also required:

- Auto Loader: Automatically feeds raw plastic granules into the injection machine.

- Air-Cooled Industrial Chiller: Maintains stable mold and machine temperature for consistent quality.

- Air Compressor (with Dryer & Pre-Filter): Provides compressed air for machine and robotic functions.

- Granulator/Crusher: Recycles scrap and runner material for reuse.

- Color Mixer: Mixes plastic granules with colorants to achieve consistent shades in the product.

Cost & Profitability

Now that we’ve covered the process and machinery, let’s talk numbers: how much you can produce, what it costs, how it sells, and the potential ROI.

Production Estimates

With the setup provided by HiTech, production capacity ranges from 7,200 to 8,600 pieces per hour. Over a 24-hour cycle, this translates to approximately 172,000 to 206,400 pieces per day.

Cost Breakdown

We have also prepared an estimated cost breakdown, based on the two main inputs: material and electricity. To keep it realistic, we have considered the conservative estimate of 70% utilization:

| Weight (Base) HIPS | 0.809 g |

| Weight (String) PTFE | 0.0285 |

| HIPS cost per floss | 0.44 PKR |

| PTFE cost per floss | 0.38 PKR |

| Material Cost | 0.826 PKR ($0.0029) |

Now, let’s move to production:

| Production (Actual) | 7200 – 8600 pcs per hour |

| Assumed Production (70%) | 6020 – 5040 pcs per hour |

| Total Power (kW) | 36.28 |

| Unit Price Assumed | 62.47 ($0.22) |

| Electricity cost per unit | 0.376 – 0.45 PKR ($0.0013 – 0.0016) |

| Total Cost per floss | 1.20 – 1.27 PKR ($0.0043 – $0.0045) |

So that’s the estimated making cost. If we now switch to the market side, our research shows numerous imported brands selling in packs of 30, 50, or 100 flossers, at a price of Rs. 5 to 15 per floss. Compared to the Rs. 1.20 cost of production.

ROI

The setup cost for one complete dental floss manufacturing line is around $56,000 (≈ PKR 18 million), covering the molding machine, mold, robotic system, and auxiliaries.

If we wholesale price of 2.27 PKR per piece, then the initial investment could be recovered in (≈ 5–6 months), even at conservative pricing.

How HiTech Makes Dental Floss Manufacturing Easy?

HiTech provides a one-window solution to kickstart your dental floss manufacturing journey. Besides covered above, we provide end-to-end complete support under one roof to make sure your setup runs smoothly and profitably.

- Local Warranty

- After-Sales Support

- Spare Parts

- Machine Installation & Training

Ready to spin your success story? Partner with HiTech today and take the first step toward building a profitable product line in the healthcare sector.