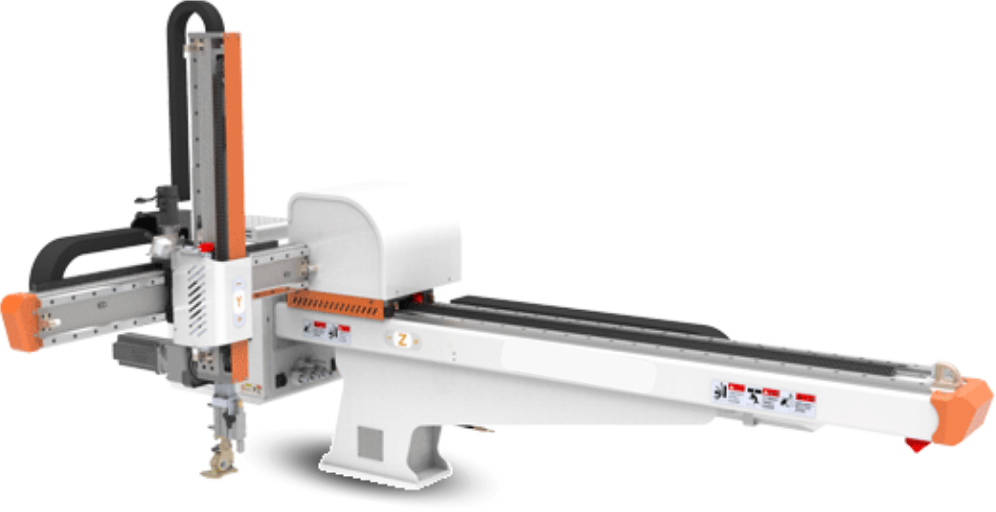

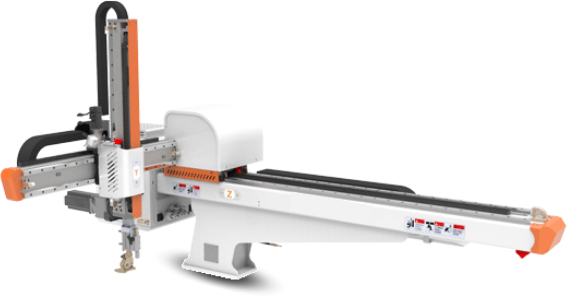

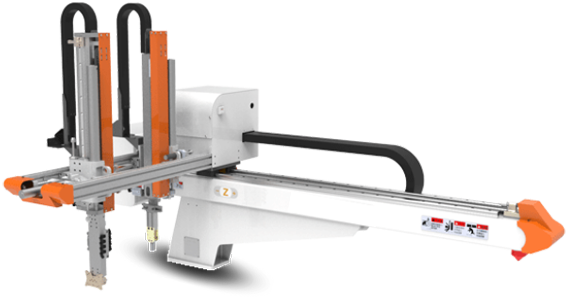

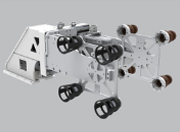

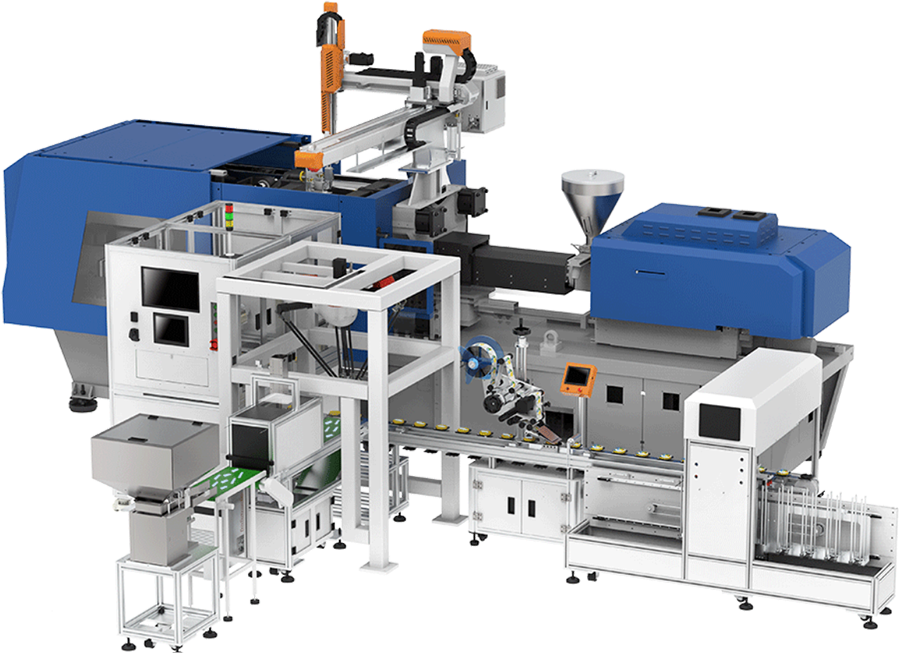

Industrial Robotic Arm automation systems provide comprehensive solutions for plastic molding injection production using industrial robotic machinery. Our industrial robot arm is equipped with varying strokes and payloads, making them suitable for automation on all types of plastic injection molding machines.

We have a large working envelope and can handle a wide range of tasks, from material handling to part removal and inspection. With our newest robot technology solutions, you can increase productivity, reduce labor costs, and improve the overall quality of your products.

Our dedicated team of experts ensures seamless integration of pick and place robot automation into your plastic molding injection production process. We offer customized solutions tailored to your specific requirements, maximizing efficiency and performance.

By leveraging the latest robot technology, we enable faster cycle times and precise operation, resulting in enhanced throughput and profitability for your business.

To satisfy a wide range of client needs, our plastics molding machine integrates R&D, design, production, and sales to provide complete automated customization. Our machines, which are designed for intelligent, adaptable, and efficient manufacturing, guarantee the highest levels of safety and dependability, increasing output and reducing downtime. Join together with us to transform your plastic production with dependable, cutting-edge equipment.

SMART

FLEXIBLE

EFFICENT

SAFE

RELIABLE

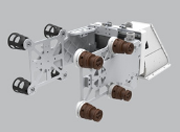

Industrial robot arm plays a critical role in plastic molding machines, improving injection molding precision and efficiency in a variety of international sectors. By enhancing speed, precision, and safety during the molding process, these customized solutions maximize productivity. They reduce labor requirements and uphold high standards of quality by handling jobs ranging from in-mold operations to post-mold activities. The latest robot technology is very beneficial to industries including food packaging, medical items, beverage containers, disposable cutlery, and cosmetics. Articulated robot arms are essential in today’s global plastic molding industry because they automate difficult processes, simplify operations, and guarantee consistent manufacturing results.

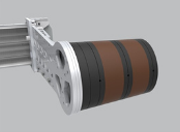

A side-entry labeling solution for mold labeling refers to a system where the labels are applied to a product as it exits the mold, rather than before it enters the mold. This allows for the labels to be applied more accurately and with less risk of damage to the labels or the product.

The system typically involves a label applicator that is mounted on the side of the mold and a conveyor belt that moves the labeled products away from the mold.

This labeling solution finds widespread application across industries like food and beverage, personal care, and pharmaceuticals due to its versatility.

It offers precise labeling, enhancing product presentation and brand visibility in competitive markets.

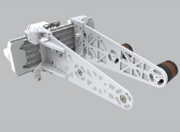

An approach where labels are put on a product as it enters the mold rather than as it comes out is known as a top-entry labeling solution for mold labeling. This makes it possible to apply labels more precisely and reduces the possibility of the labels or the product getting damaged.

Generally, the system consists of a conveyor belt that feeds the products into the mold and a label applicator that is fixed on top of the mold. Industries like food and beverage, personal care, and pharmaceuticals frequently employ this kind of labeling solution.