For over 22 years, Tederic has been building injection molding machines that manufacturers rely on every day. As an official supplier and partner, we bring you these workhorse machines that combine proven reliability with thoughtful innovation. What began as a family workshop in Hangzhou in 2003 has grown into a global manufacturer, with factories and support centers spanning from Asia to Europe and the Americas.

The Tederic difference shows in machines that just keep working – from their first TRK series that established their reputation, to the versatile DREAM line that handles complex jobs with ease. These aren’t flashy machines packed with unnecessary features, but solid performers built for real production floors. They’re designed to minimize downtime, adapt to your growing needs, and include practical innovations that help operators do their jobs better.

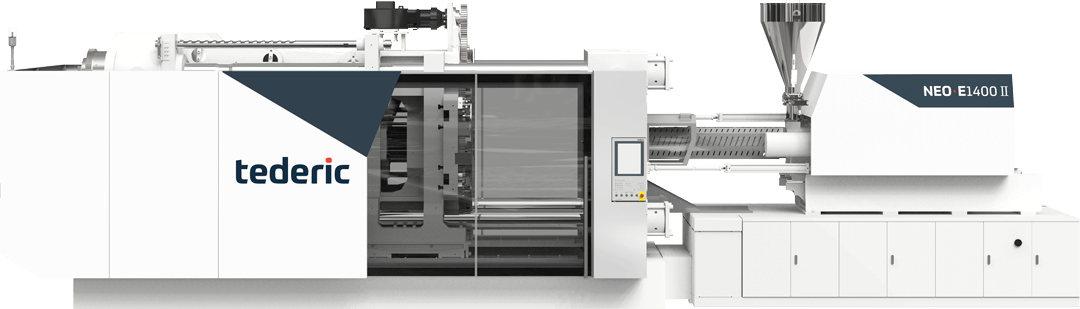

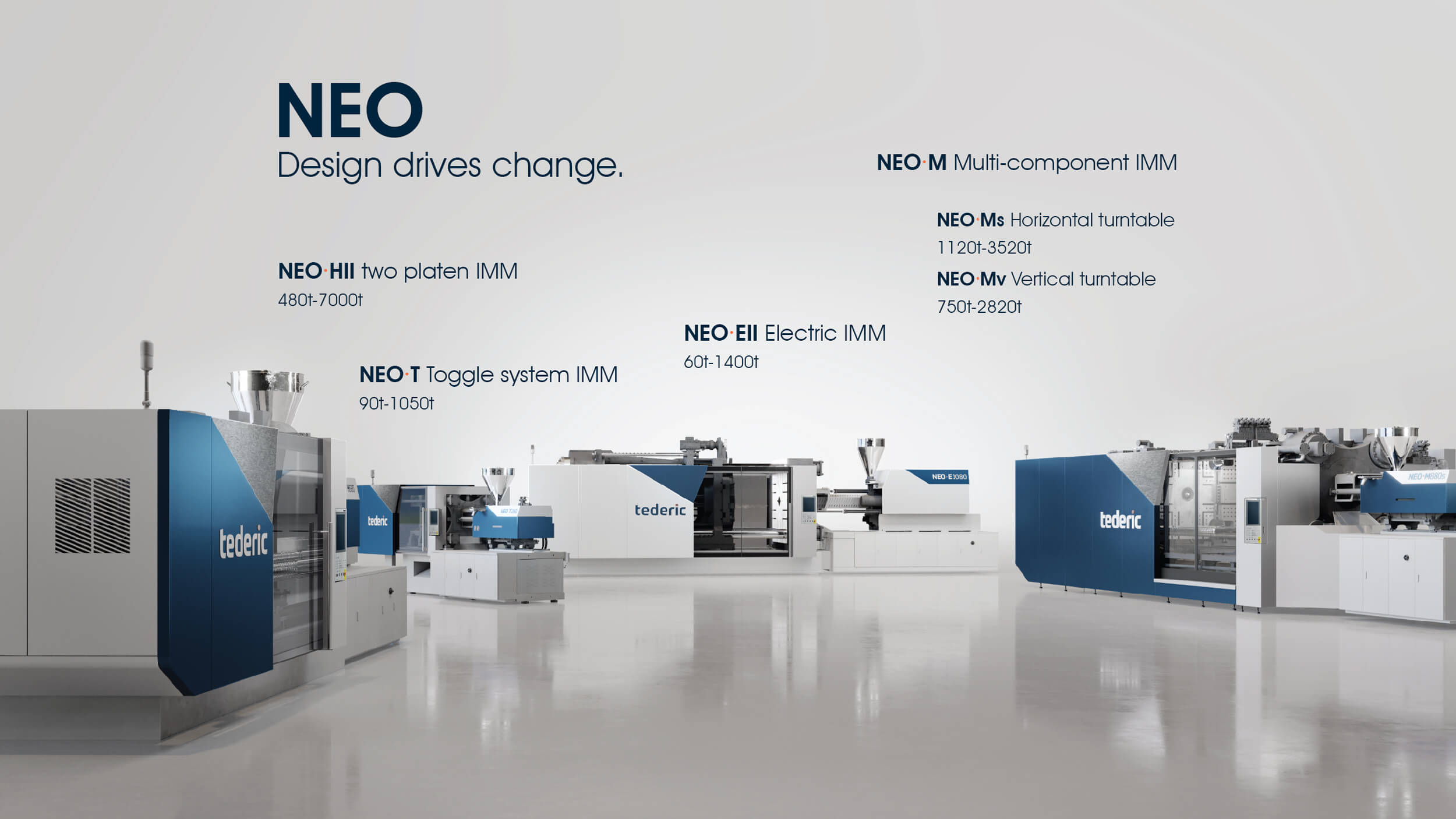

HiTech Machinery is proud to supply Tederic NEO Series machines because we believe in them. More importantly, our customers believe in them too. When you choose a Tederic best Injection Molding Machine through us, you’re not just getting equipment – you’re getting our commitment to help you succeed with it. From selecting the right model to keeping it running smoothly, we’re here to support your production goals. Let’s talk about how a Tederic machine could work for you.

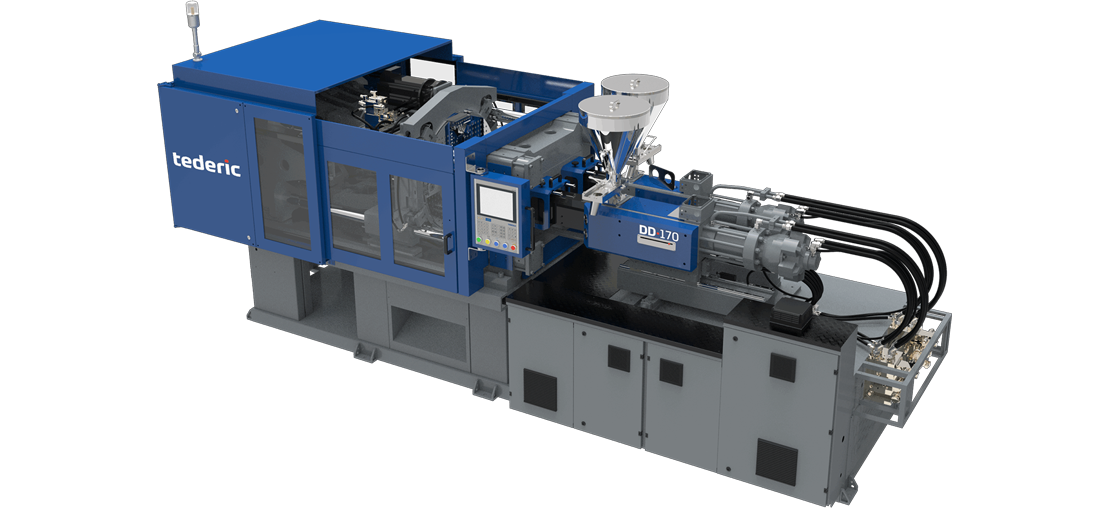

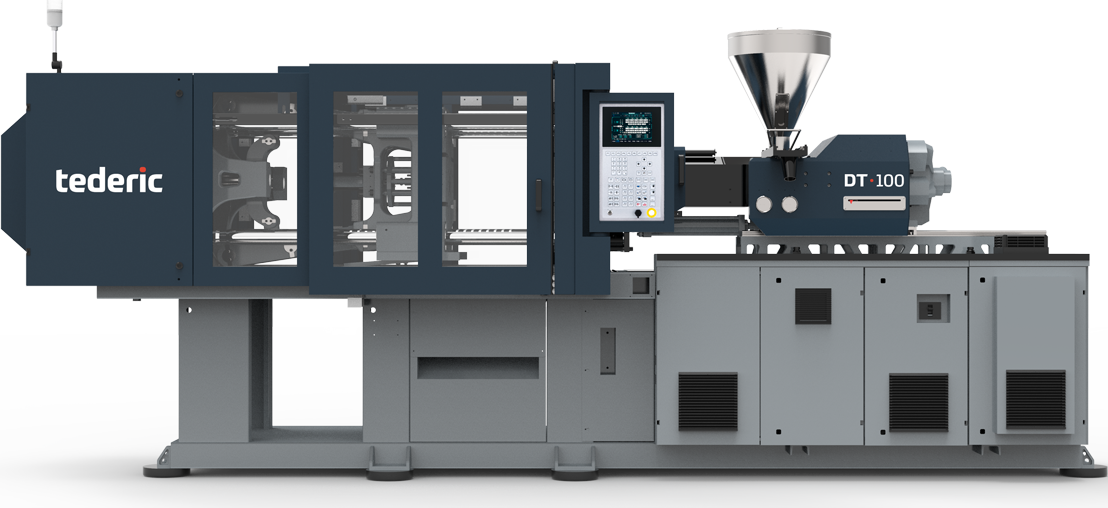

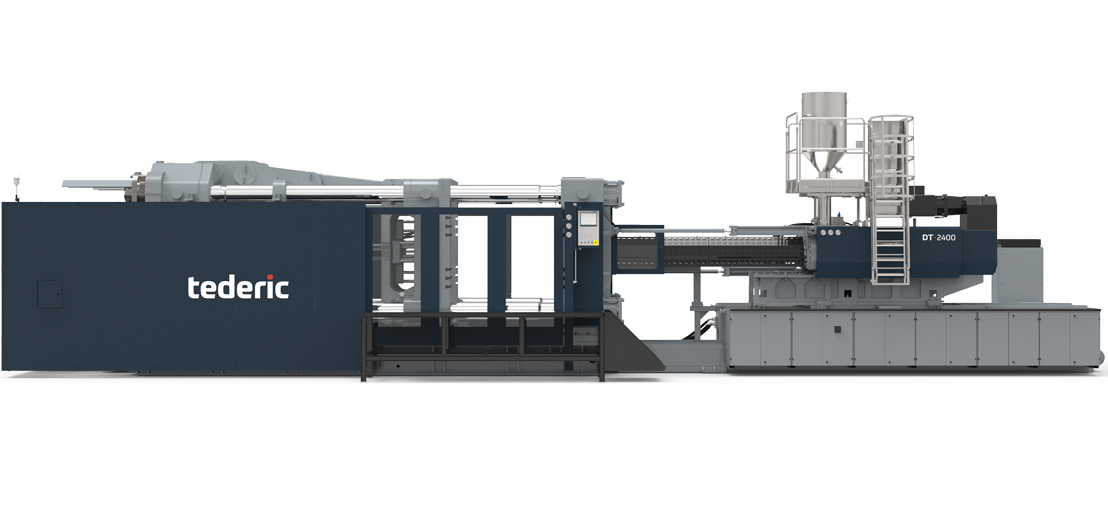

Explore our comprehensive range of plastic injection molding machines, featuring advanced models from top manufacturers. Tederic machines, including the DD Machine, DT Machinery, NEO E 2, NEO H 2, Pallet Machine, PET Preform Machine, and PVC Machine—designed to handle a wide variety of production requirements with cutting-edge technology and reliable output.

At HiTECH Machinery, we bring you reliable and high-performing plastic machinery, built to handle real-world manufacturing needs. Whether you’re in the automotive, medical, home appliances, electronics, packaging, or technical molding sectors, we’ve got the right solutions to help you produce with more control and less hassle. We proudly serve customers across the UAE, Pakistan, and beyond—offering support, guidance, and machines that simply get the job done. Let’s work together to find the Tederic Moulding Machines model that fits your business best.

▶ Equipped with 2 sets of 8 ton electric furnace, using advanced manufacturing technology

▶ An annual output 11,000 tons of castings (<20 tons/piece)

▶ Using the world's top CNC brands, such as SKODA, TOS, Kurashiki and Toshiba, etc, which can meet the needs of plate, cross head, injection seat and other casting processing, the maximum processing 10000 tons of injection molding machine plate, the accuracy is as high as 0.01mm; The annual output value of processing is 30 million rmb

▶ Welding robot is used to complete the automatic welding of critical welds, with hardware and software functions such as laser tracking, arc tracking and starting point locating. Annual production capacity of 9000 tons machine body

▶ Annual output of sheet metal reaches 3000 tons

▶ 3m/min Sheet metal automatic suspension spray wire 1 piece

Injection Molding Machine Assembly

Die Casting Machine Assembly

At HiTECH Machinery, we take pride in offering Tederic machines that are trusted by manufacturers across the region. These machines are built to deliver stable, consistent performance you can rely on every day. From the energy-efficient and precise NEO E-2 Injection Molding Machine to the fast and durable NEO H-2, each model is designed to meet real production demands. The Pallet Molding Machine is perfect for handling heavy-duty, high-volume work, while the PET Preform Machine ensures smooth, accurate preform production. For more specialized needs, our PVC Machines are made to handle the challenges of PVC molding with ease. When it comes to dependable equipment, Tederic machines supplied by HiTECH Machinery stand out for all the right reasons.