For over two decades, Tederic has been building injection molding machines that manufacturers rely on every day. Hitech Machinery brings these powerful machines that combine proven reliability with thoughtful innovation.

With in-house manufacturing of key components, including precision casting, large-scale welding, CNC machining, electrical and machine assembly, and software development, Tederic maintains full control over quality, cost, and delivery, ensuring reliable performance at every stage.

Tederic injection molding machines are sold in over 140+ countries, and HiTech Machinery is an exclusive partner and supplier of their injection machines in Pakistan and the UAE.

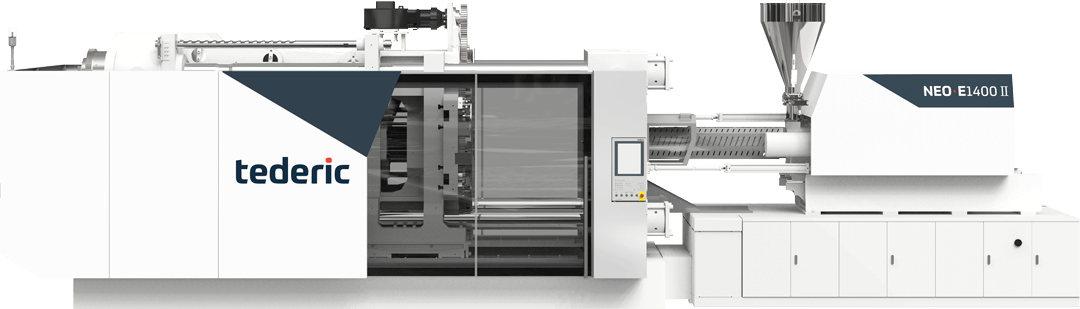

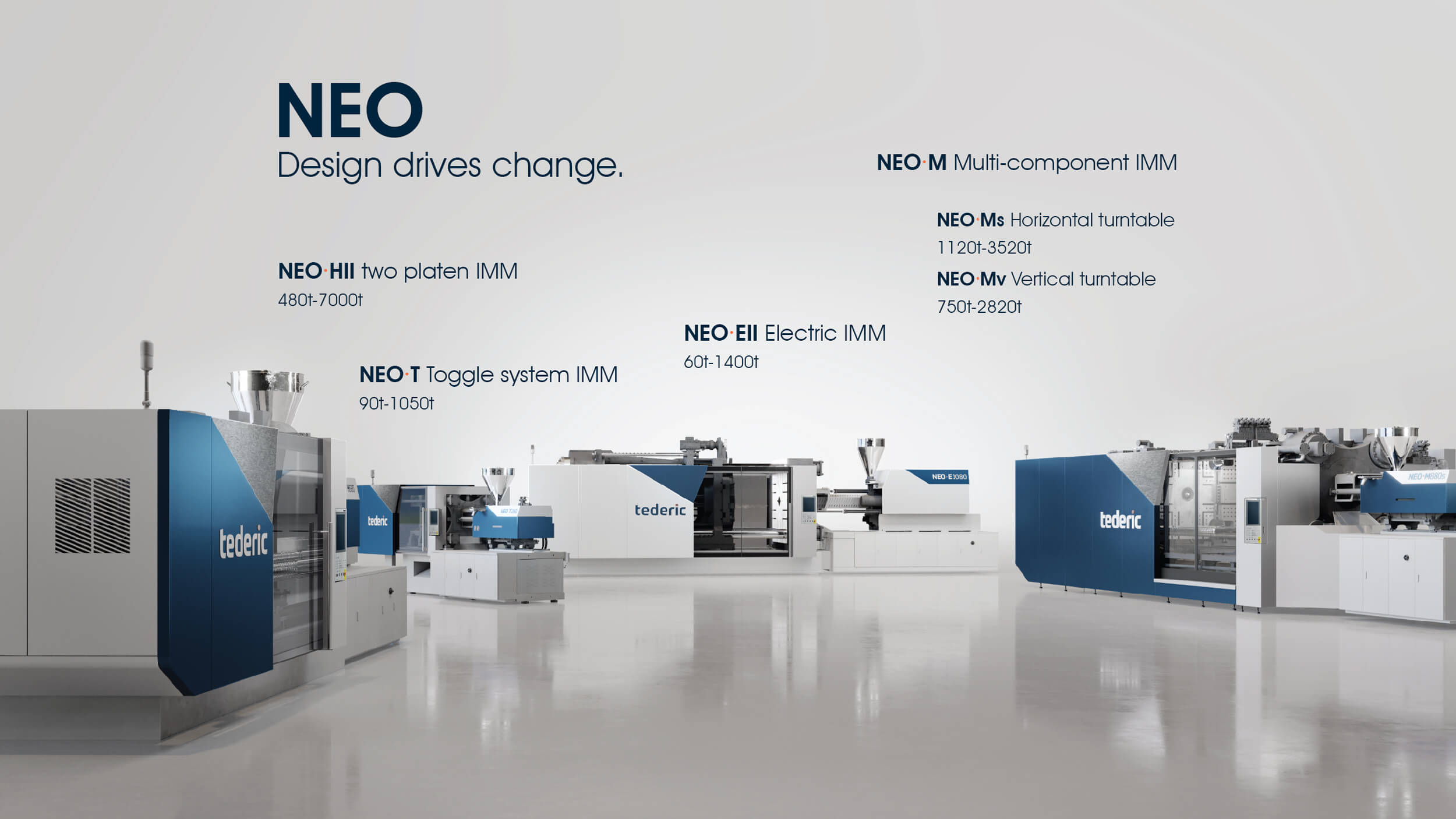

Our Tederic injection molding machine lineup includes high-speed toggle system IMMs, energy-efficient servo-hydraulic machines(NEO T), all-electric machines (NEO E), two-platen IMMs (NEO H), solutions for multi-component/color molding (NEO M), and dedicated models for PET preforms and PVC processing. Besides Tederic, HiTech also deals in injection molding machines of UWA, another global Chinese brand trusted by multiple manufacturers.

HiTech Machinery brings the most high-performing plastic machinery, built to handle real-world manufacturing needs. Whether you’re in the automotive, medical, home appliances, electronics, packaging, or technical sectors, we have complete manufacturing solutions to help you produce with more control and less hassle.

▶ Equipped with 2 sets of 8 ton electric furnace, using advanced manufacturing technology

▶ An annual output 11,000 tons of castings (<20 tons/piece)

▶ Using the world's top CNC brands, such as SKODA, TOS, Kurashiki and Toshiba, etc, which can meet the needs of plate, cross head, injection seat and other casting processing, the maximum processing 10000 tons of injection molding machine plate, the accuracy is as high as 0.01mm; The annual output value of processing is 30 million rmb

▶ Welding robot is used to complete the automatic welding of critical welds, with hardware and software functions such as laser tracking, arc tracking and starting point locating. Annual production capacity of 9000 tons machine body

▶ Annual output of sheet metal reaches 3000 tons

▶ 3m/min Sheet metal automatic suspension spray wire 1 piece

Injection Molding Machine Assembly

Die Casting Machine Assembly

Tederic injection molding machines feature the latest servo system that enables the system to reach maximum pressure in as little as 28 ms. Their advanced energy control can save up to 80% electricity compared to traditional hydraulic systems. They are available in about hydraulic, all-electric, and even multi-color/component options to meet each customer’s unique product requirements.

What is the Tederic brand and is it considered a premium IMM manufacturer?

Tederic is a world-leading provider of molding solutions for plastic and metal molding. In Pakistan and the UAE, HiTech Machinery is Tederic’s exclusive partner, offering a wide range of high-speed, all-electric, and hydraulic machines.

Do you have Tederic Injection Molding Machine spare parts?

Yes, HiTech Machinery provides after-sales spare parts for Tederic machines. Spare parts and technical support are offered locally in Pakistan and the UAE.

What products can be made using Tederic IMM?

With the wide range of Tederic series available at HiTech Machinery, almost any rigid plastic product can be manufactured. These include PET preforms, automotive parts, appliance housings, thin-wall containers, medical components, electronic parts, logistic crates, and other everyday plastic items.

How energy-efficient are Tederic all-electric machines?

Energy efficiency is one of Tederic’s key strengths. Not only their all-electric machines, but also their servo-hydraulic models, are among the most energy-efficient in our lineup thanks to advanced servo-driven systems. In addition, the PLC displays real-time electricity consumption per part, which allows better monitoring and optimization.

How long does it take to deliver a new Tederic IMM?

Some standard models are readily available in stock. For custom builds, you can expect approximately 50–60 working days for manufacturing, followed by 30–35 working days of transit time after receipt of the down payment.

What is the standard warranty period for Tederic machines?

We offer up to 2 years of local warranty on Tederic machines: 2 years on tie rods, and 1 year on electrical components as well as the screw and barrel, provided virgin material is used.

What is the price of a Tederic Injection Molding Machine?

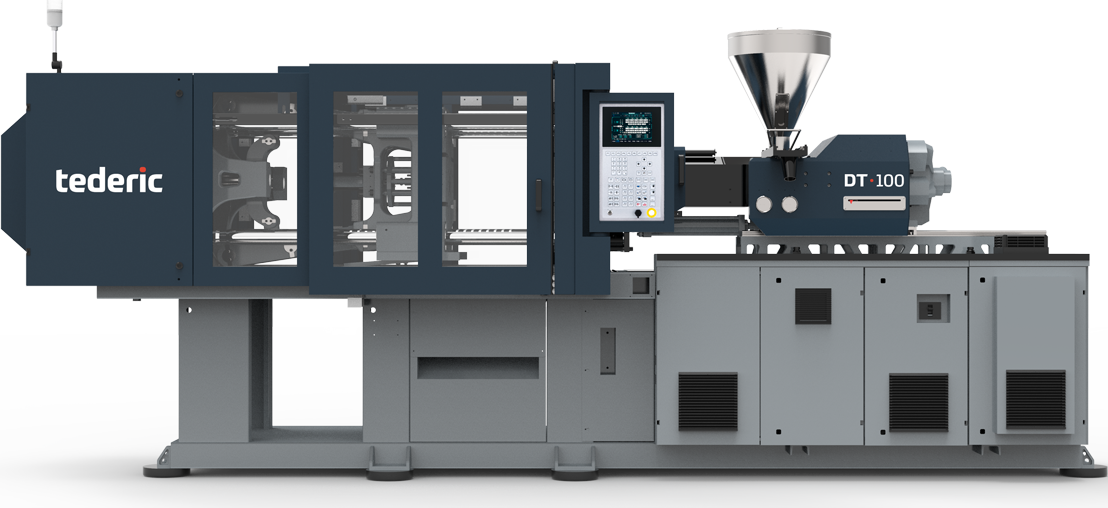

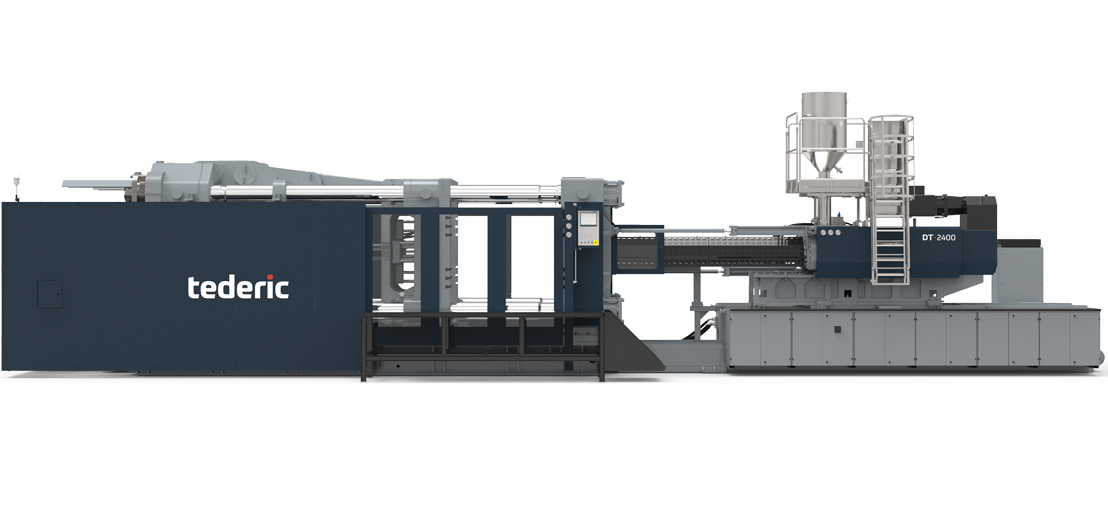

The price depends on the machine series, clamping force (tonnage), and optional add-on features. The higher the clamping force, the higher the price. For reference, a DT100 model starts at approximately USD 20,000.

What are the main Tederic machine series and how do they differ?

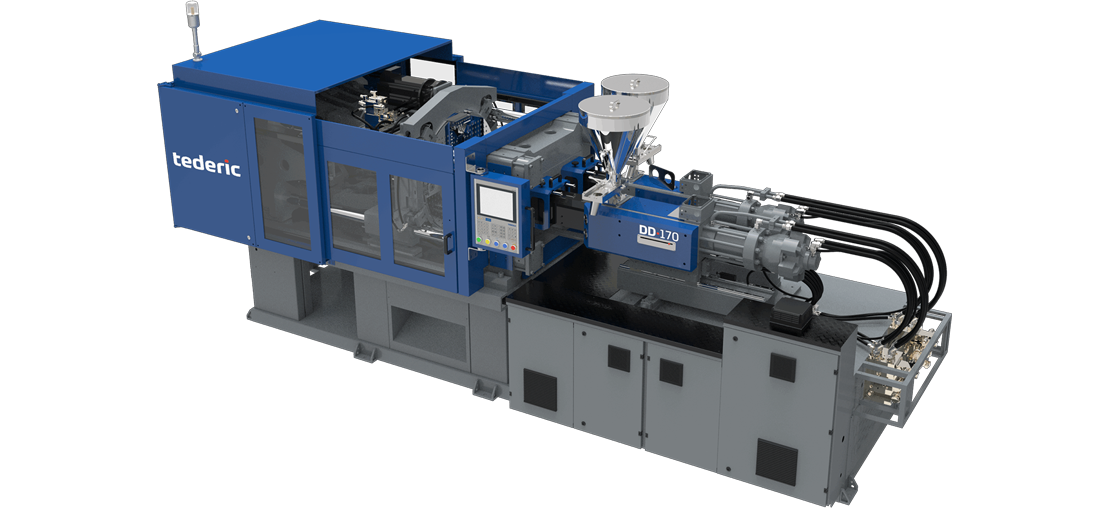

Tederic offers all types of injection molding machines, including a standard hydraulic DT series, a high-speed NEO T series, an electric NEO II series, two platen NEO HII Series, double color DD series, and multi-component NEO M series.

How does Tederic compare with brands like Haitian?

Although Haitian is one of the oldest names in injection molding, Tederic has also been in the industry for over two decades. Tederic has supplied machines to major automotive manufacturers, such as BYD, and currently sells its machines in more than 140 countries worldwide.

Can you make multi-colored parts with Tederic Machines?

Yes, Tederic offers dedicated solutions for multi-color molding. The DD series is designed for double-color or double-component parts, while the NEO M series supports multi-colored plastic parts. These machines use multiple injection units working sequentially to produce multi-colored parts in a single molding cycle.