Piston Air Compressor

NANJING SHANGAIR is a leading high technology enterprise specializing in research, development, manufacturing, and sales of high quality reciprocating and piston air compressors under the brand “Shanghai” With patented technologies and advanced manufacturing processes, Shangair’s products meet or exceed global standards.

They ensure quality through advanced equipment and a modern Quality Management system. HiTech Machinery is the exclusive distributor of Shangair’s piston air compressor, offering superior products, compressed air cleaning systems, and timely technical support nationwide.

Smart Energy Saving Air Compressor Energy Management and Control Internet Service platform.

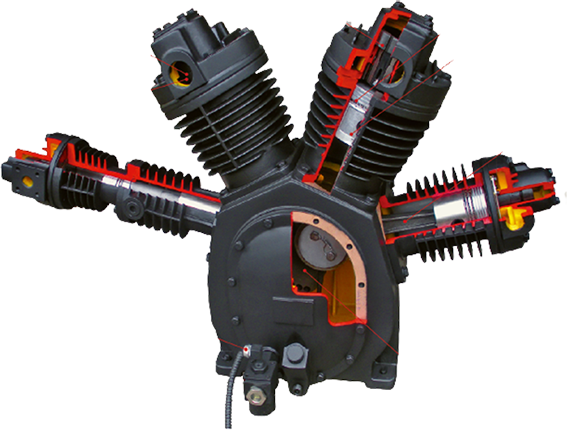

Shangairs Patented Technology

(Patent Number: 00220347.2).

The valve plate is free from fracture during its working life!

This section features the awards and certificates given out for exceptional accomplishments. A significant turning point is marked with honors, which recognize performance, dedication, and accomplishments across a range of fields. This show serves as a tribute to talent, tenacity, and the pursuit of excellence. Along with professional qualifications, it contains awards for leadership, community service, and academic accomplishment.

Piston ring compressors are used in a wide range of industries for various applications. Some of the industries where piston ring compressors are commonly used include:

The piston screw air compressor is built with a durable stainless steel belt valve and incorporates redundancy design and multi-protection measures for safe operation. It offers automatic flow rate adjustment, and periodical drainage, and maintains a low discharge temperature. With low oil consumption, it ensures high reliability and cost-effective operation.

Introducing our High-Pressure Air Compressor series, delivering 6.0mᶾ/min air discharge at 4.0Mpa pressure with a 67KW motor running at 630r/min. Weighing 1850KG and measuring 2500 x 2250 x 2000 mm, this piston compressor is powerful yet compact, perfect for industrial applications requiring high-pressure air piston compressors. Built for reliability and efficiency, our piston compressors ensure consistent performance, making them ideal for various industries.

Model: 6.0/8/40

Air Discharge: 6.0mᶾ/min

Pressure: 4.0Mpa

Motor Power: 67KW

Running Speed: 630r/min

Weight: 1850KG

Dimensions Package: 2500 x 2250 x 2000 (mm)

Introducing the SHANGAIR High-Pressure Piston Air Compressor Series, designed to meet your industrial air compression needs with exceptional performance and reliability. Model WH-1.2/30 boasts a formidable F.A.D (Free Air Delivery) of 1.2 M3/min, ensuring a steady supply of compressed air. With a pressure rating of 3.0 MPa and powered by a robust 15 kW motor, this compressor delivers power where it’s needed most. Whether you’re operating pneumatic tools, machinery, or pneumatic systems, the SHANGAIR High-Pressure Piston Air Compressor Series is your trusted companion for efficiency and productivity.

Model: (WH-1.2/30)

F.A.D: (1.2 M3/min)

Pressure: (3.0 MPa)

Power: (15 kw)

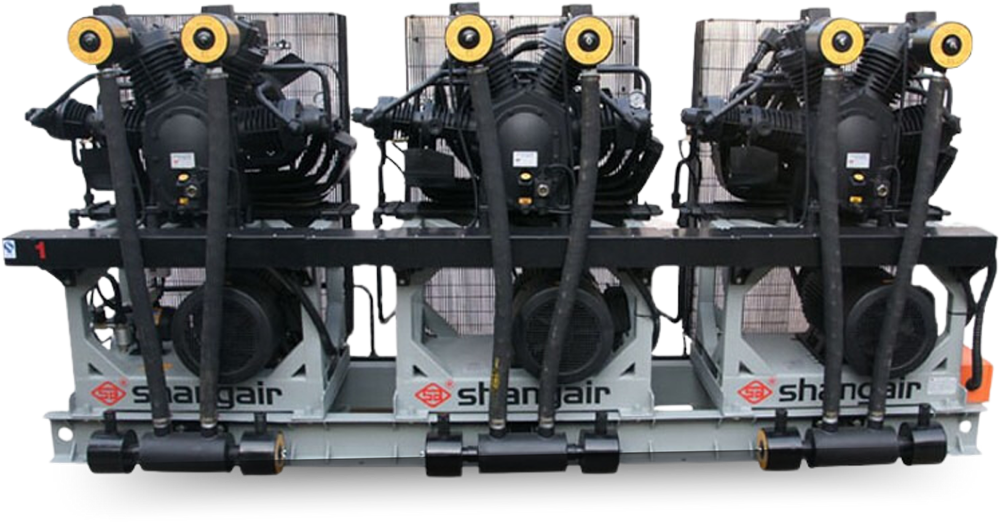

Introducing our medium-pressure piston air compressor, model 09SH, designed for efficiency and performance in industrial applications. With a robust 3-09SH-1840T model number, this piston compressor delivers a reliable 4.8 Nm3/min air discharge at 4.0 Mpa discharge pressure. Featuring three levels of compression and powered by three 18.5 KW motors, this piston compressor runs at a smooth 730 r.p.m. Despite its power, it’s compact and easy to handle, weighing just 1750 KG and measuring 3462x1100x1600 mm. Trust our medium-pressure piston air compressor for consistent and reliable performance in your operations.

Model No: 3-09SH-1840T Nm3/min

Air Discharge: 4.8 Mpa

Discharge Pressure: 4.0

Levels of Compression: 3

Motor Power (KW): 18.5×3

Running Speed: 730 r.p.m

Weight : 1750 KG

Size (LxWxH): 3462x1100x1600 mm

HiTech Machinery offers comprehensive 360° services for customer equipment throughout its lifetime. This includes implementing IoT technology, intelligent analysis, dynamic maintenance, and equipment coordination. We also provide intelligent manufacturing services aimed at helping our customers achieve higher efficiency.

Technology Services:

Plastic Machinery takes pride in assisting our customers and is committed to solving all equipment and technology-related issues within 24 hours, whether before, after, or during your purchase. Our consultation and services are provided free of charge. After a successful trial operation, our after-sales engineers will provide regular training to your operators. During the warranty period, if your equipment experiences any breakdowns, our head office will provide support 24/7.