We are pleased to offer state-of-the-art machinery for the production of PET stretch blow molding machine bottles for a variety of industries, including water, juice, carbonated drinks, cooking oil, detergent, cosmetics, and medication. Our advanced auto PET stretch blow molding machines are designed with energy efficiency in mind and have been shown to save over 40% of energy compared to traditional methods.

This results in significant cost savings for our clients, as well as a reduced environmental impact. Our stretch blow molding machines are built to the highest standards of quality and performance and are backed by our commitment to superior customer service and support.

If you are looking to improve the efficiency and profitability of your PET bottle production, look no further than HiTech plastics.

This series is widely used to produce containers for carbonated drinks, mineral water, edible oil, pesticides, and cosmetics, and also for making jars and hot filling containers. That container ranges from a 5-gallon bucket, lampshade to an eyes drop bottle.

Our high-quality, reliable stretch blow molding machines are top sellers in over twenty provinces and are exported to Southeast Asia, the Middle East, Middle Asia, and South Africa. Clients consistently praise our machines and services.

Semi Automatic Series

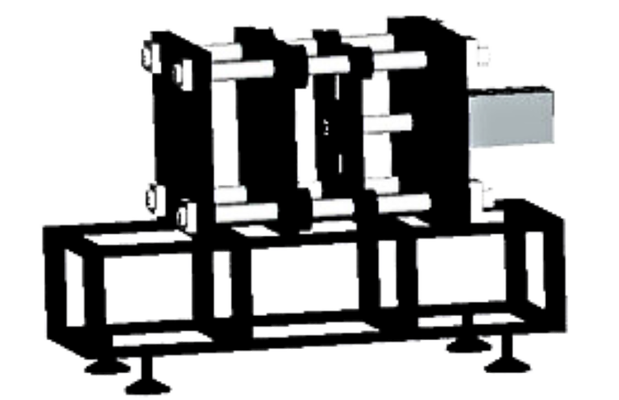

The HT-880 is a semi auto pet blow molding machine designed to meet CE standards, it has a microcomputer control system for precise and steady control of technical parameters and is easy to operate. It’s suitable for producing bottles for carbonated drinks, mineral water, cosmetics, hot-filling, and oil bottles with handles.

This semi auto pet blow molding machine can produce a wide range of bottle sizes and shapes and is commonly used in the beverage industry for bottling water, soda, and other drinks.

Features

- Bottle Production Range: 0.1L to 6L (1 cavity).

- High Output Capacity: Up to 850 for 0.1L with a two-cavity blow mold.

Welcome to our top-notch plastic molding machine production company. Our cutting-edge machinery can be customized to match your specific requirements, whether you’re looking to create mineral water containers, fizzy drink bottles, or other plastic products. Use our dependable and cutting-edge technologies to precisely and efficiently the plastic product you’ve always wanted. And go to our plastic products manufacturing machines page.

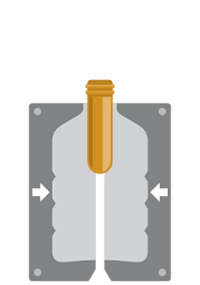

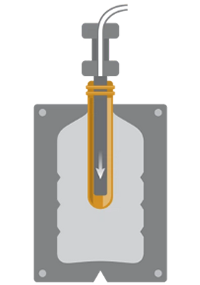

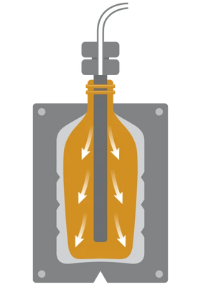

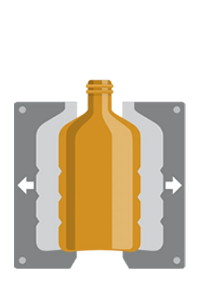

To show the final product, the preform is ultimately removed after being stretched with a core rod and inflated to precisely fit the mold. Your items will always be prepared for the following phase of production thanks to this flawless process.

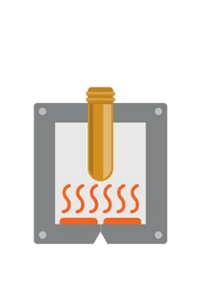

Greetings from the cutting-edge plastic molding innovation! Your items will be perfectly shaped to your specifications by our HT-880 equipment. To ensure excellent and reliable results every time, each device has a blow unit for precise bottle blowing and a preform heater for ideal preform heating.

Explore our range of Stretch Blow Molding for the production of bottles and jars. We offer precise, effective, and adaptable packaging solutions, and our lineup includes the HT 900 Semi Automatic, HT 700 Jar Semi Automatic, and HT 600 Semi Automatic machines. Maximize your output with our cutting-edge technologies.

HUARE is a well-known company with exclusive rights to its intellectual property that specializes in Hitech plastics and stretch blow molding. Our areas of expertise include material loading and mixing, central feeding systems, central cooling systems, dehumidification and drying, granulating and shredding, and mold temperature control. With more than a dozen series and hundreds of product parameters, we offer expert, bespoke system configurations made to fit each customer’s particular requirements.