HiTECH PARTNER

Focusing on continuous innovation and excellent customer experience.

Founded in 1985, Ningbo Yonghua Plastic Machinery Manufacturing Co., Ltd. specializes in plastic injection molding machines. The company employs over 400 professionals, manages assets worth 500 million yuan, and operates a modern manufacturing facility spread across 100,000 square meters.

Built on a modern management concept, UWA earned ISO 9001:2015 Quality System Certification and adopted lean production lines and 6S management practices to ensure consistent and high-quality output.

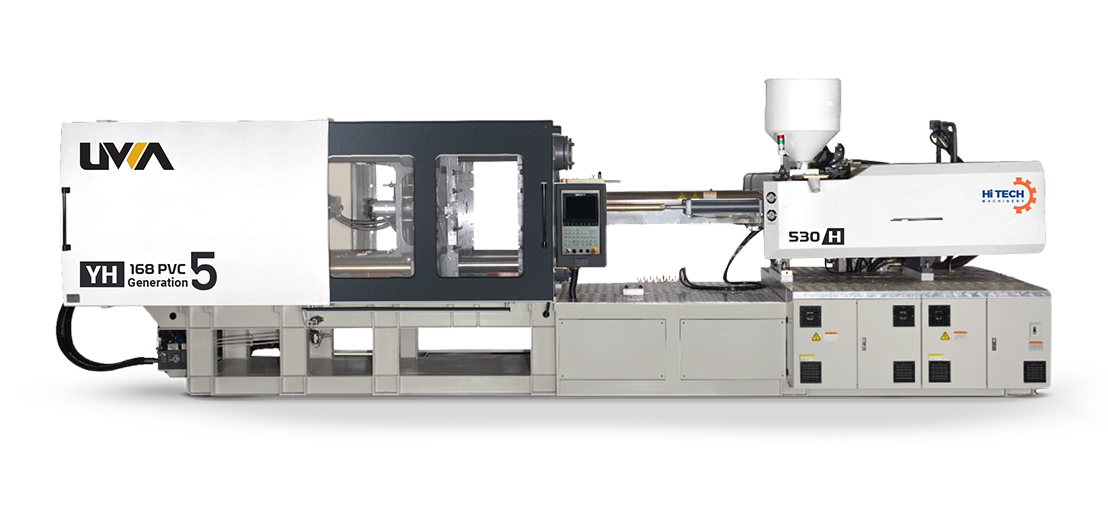

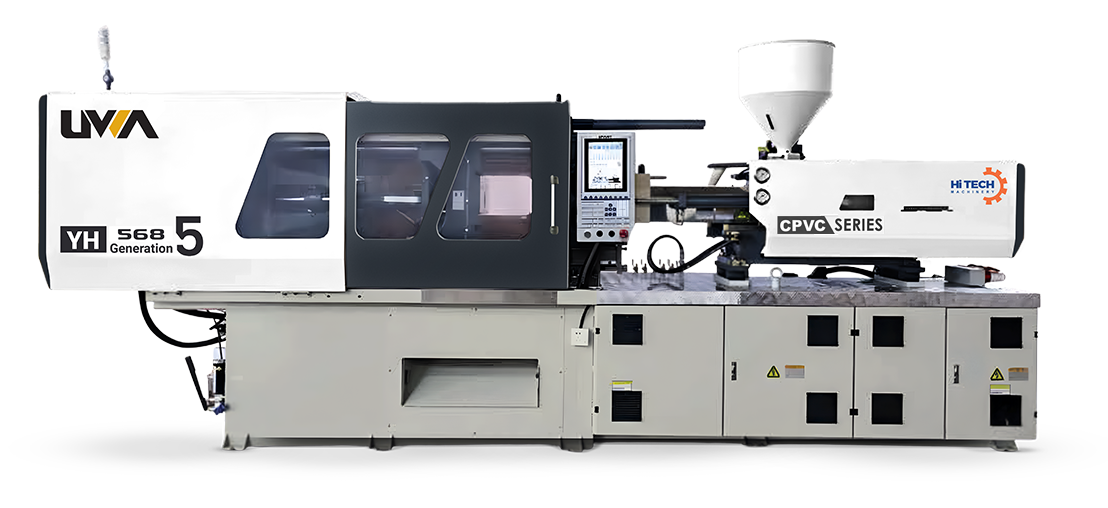

HiTech Machinery supplies a range of UWA injection molding machines. Our lineup features the YH-5 Generation, YH Series, YH PVC Series, YH-5 CPVC, YH-5 PET, YH/SP Thin Wall Series, YH Basket Series, YE All-Electric, YE Medical, and YU Two-Platen Series. Along with UWA machines, HiTech Machinery also supplies injection molding machines from Tederic, another global brand in injection molding.

Hitech Machinery’s UWA injection molding machines are suitable for a wide range of product applications. Our UWA machines are widely used for manufacturing plastic parts across automotive, food, medical, packaging, logistics, electronics, and household industries.

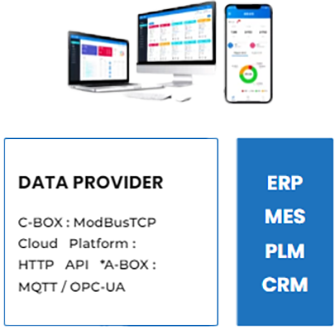

UWA machines employ the I LINK Technology feature, with integrated systems that connect equipment to a centralized network for automation, data analytics, and real-time monitoring of plastic molding machine operations. With internet-based remote access, this system helps manufacturers track performance, gain insights, and improve operational efficiency.

UWA is an industry leader in injection molding solutions with a global support network and advanced production capabilities. Their strategic alliances and comprehensive understanding of market trends keep them at the forefront of the industry.

UWA Injection Molding Machines feature robust clamping and plasticizing units, paired with an energy-efficient E-charge system, available in either hydraulic or electric configurations, depending on the machine type.

What is the UWA brand, and is it reliable?

Founded in 1985, Ningbo Yonghua Plastic Machinery Manufacturing Co., Ltd. (UWA) specializes in plastic injection molding machines. UWA is one of the top 10 manufacturers of injection molding machines in China and has been partnering with HiTech for a decade, bringing the latest Generation 5 hydraulic and all-electric injection molding machines to Pakistan and the GCC.

What are the top series of UWA, and how do they differ?

At HiTech Machinery, we offer different UWA series based on application, material type, and working mechanism. We have the YH and YHS series for general-purpose applications, YHSP high-speed series for products like thin-wall containers, all-electric YE series for medical and food-grade manufacturing, YU two-platen machines for large crates and baskets, and some material-specific, PET, PVC, and CPVC series.

What is the price of UWA Injection Molding Machine?

Pricing depends on machine tonnage, specific series, and add-ons like E-Charge. As the tonnage increases, the cost rises sharply. Similarly, all-electric and two-platen machines are priced higher than standard hydraulic models. As an estimate, a 100-ton machine starts at around 6.5 million PKR (approximately USD 17,000) without auxiliaries.

What is the standard warranty period for UWA machines?

We offer a one-year warranty on hydraulic and mechanical parts. The screw and barrel may be excluded if non-virgin material is used in manufacturing.

How does UWA compare to Haitian injection molding machines?

Like Haitian, UWA is also one of the top injection molding machine manufacturers in China. Both brands offer complete model ranges designed for different applications, and UWA remains a cost-effective option compared to many other brands.

How energy efficient are UWA all-electric machines?

UWA all-electric YE machines use the latest servo-based systems, which can save 20 to 40% energy compared to traditional hydraulic counterparts.

Are UWA injection molding machines suitable for high-precision medical parts?

Yes. At HiTech Machinery, we offer a dedicated YE Medical Series designed specifically for high-precision medical parts. The available tonnage range in this series is from 60 to 300 tons.

What is the best UWA machine for packaging applications?

It depends on what you want to package. For preforms, we offer the dedicated YH PET series. For thin-wall containers, there’s YHSP series. For other general packaging applications, the YH and YHS series are recommended.

What products can be made with UWA IMM?

With a wide tonnage range and multiple machine options, nearly all types and sizes of plastic parts can be produced using our hydraulic, all-electric, and two-platen machine series.

What is the average delivery time for a new UWA machine?

Usually, we have standard machines in stock. However, for a customized machine, you can expect the following timeline: machine manufacturing takes around 90 to 110 working days, mould manufacturing takes around 80 to 90 working days, and transit time is about 35 to 40 working days after receipt of the 50% down payment.