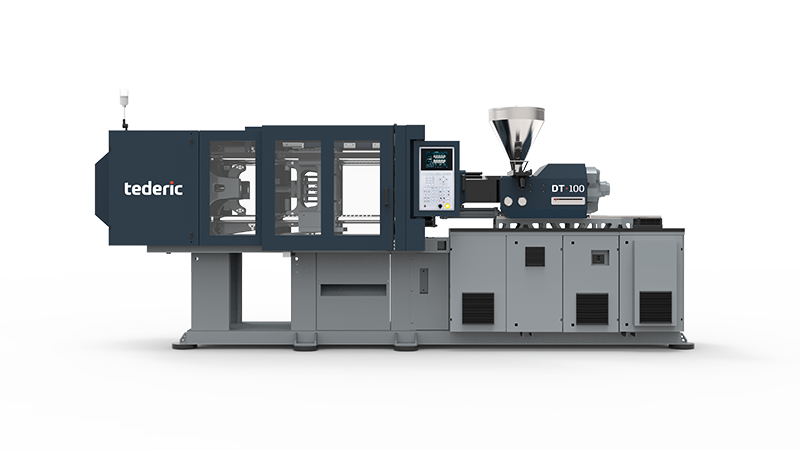

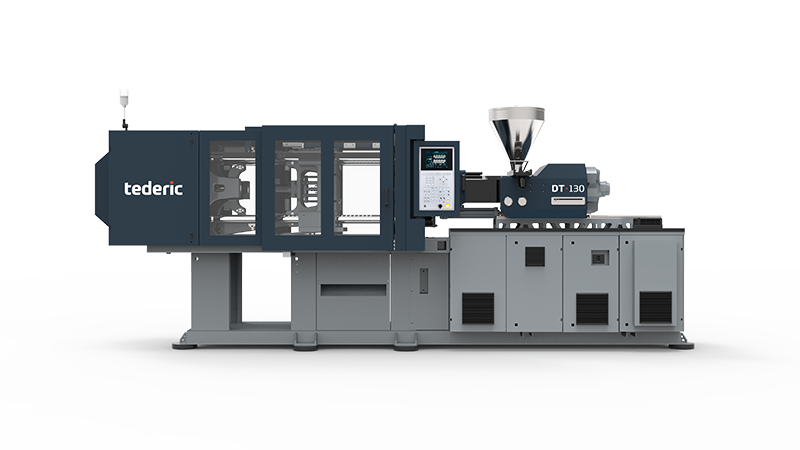

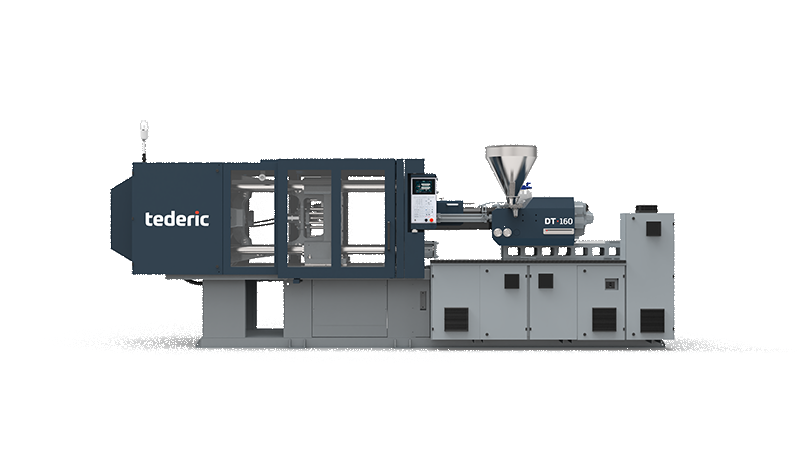

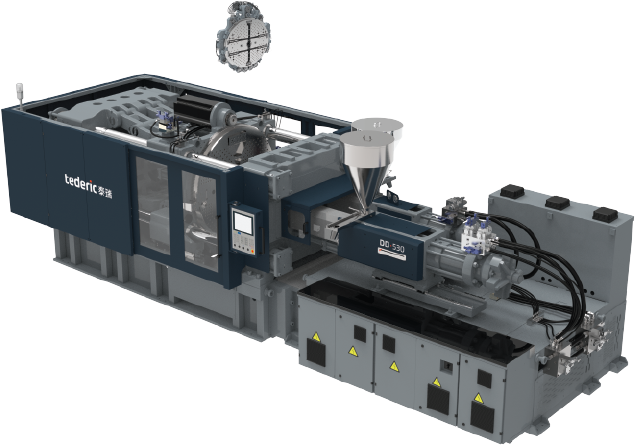

The Tederic PVC Injection Molding Machine is engineered for high-performance production of PVC components, offering exceptional precision and reliability for a wide range of applications. This machine combines advanced hydraulic and electric technology to provide high-efficiency production with reduced energy consumption. Its optimized design ensures fast cycle times, making it perfect for industries such as automotive, construction, electrical, and packaging. With the ability to produce complex parts with tight tolerances, the PVC Pipe Making Machine is a trusted solution for large-scale manufacturing needs.

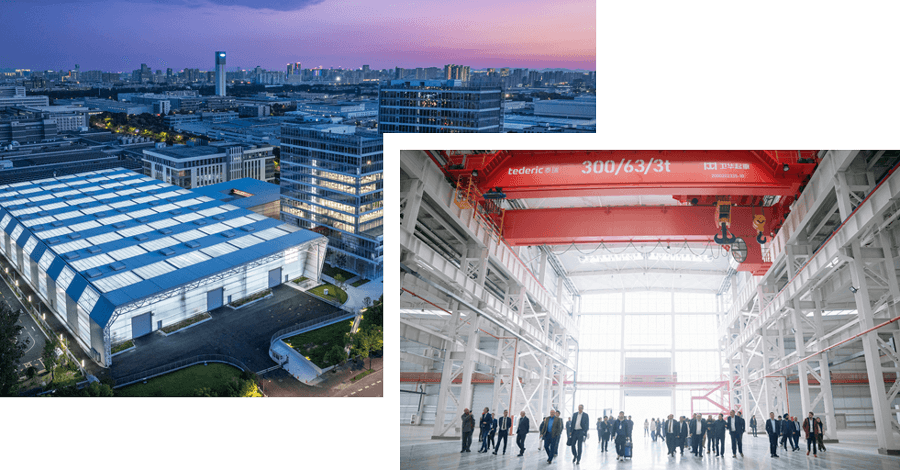

Hi-TECH MACHINERY, we offer the Tederic PVC Extrusion Machine, designed to deliver superior quality and enhanced productivity. With state-of-the-art control systems and a robust design, it ensures smooth, stable operations, minimizing downtime and enhancing the production of PVC-based products. Ideal for businesses aiming to improve operational efficiency and reduce manufacturing costs, this machine provides an energy-efficient solution while maintaining optimal product quality.

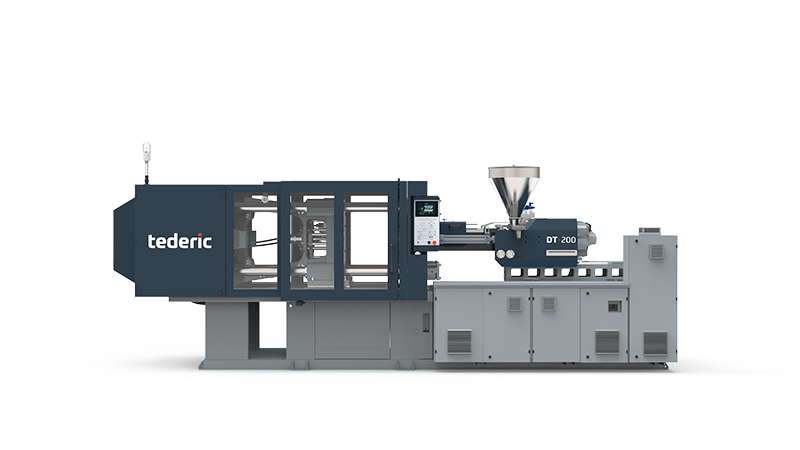

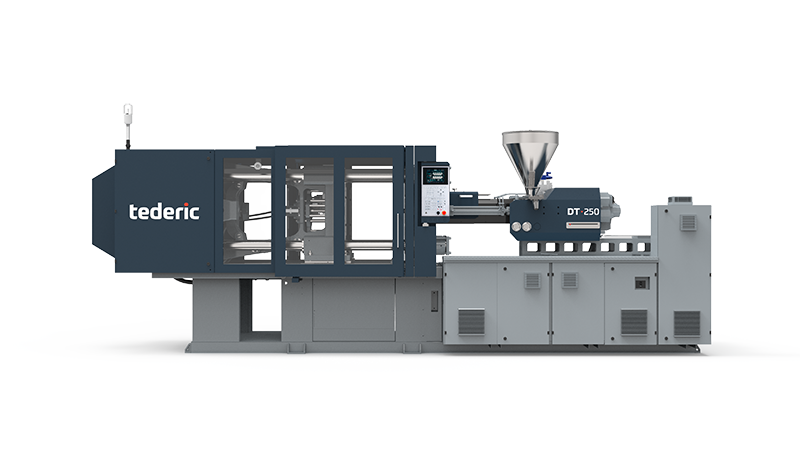

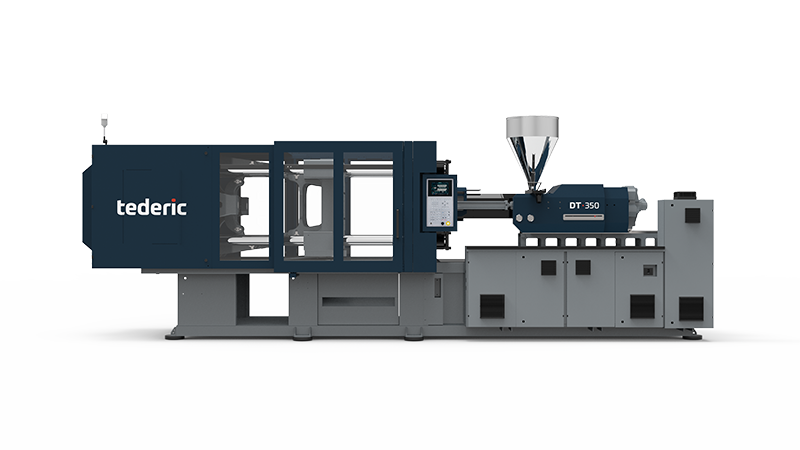

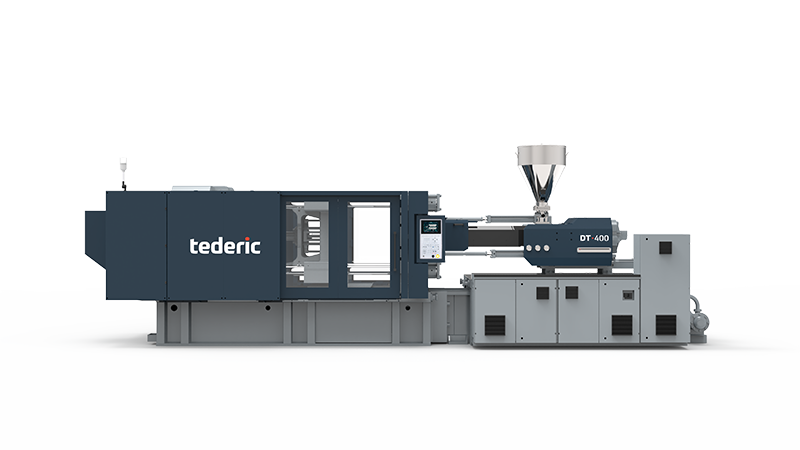

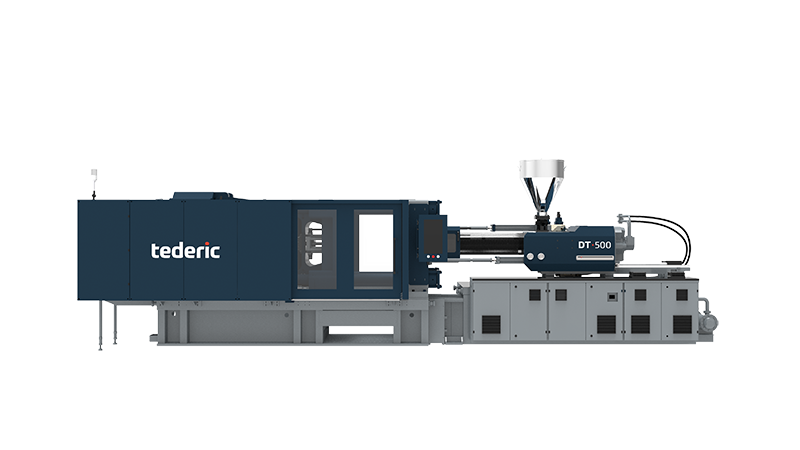

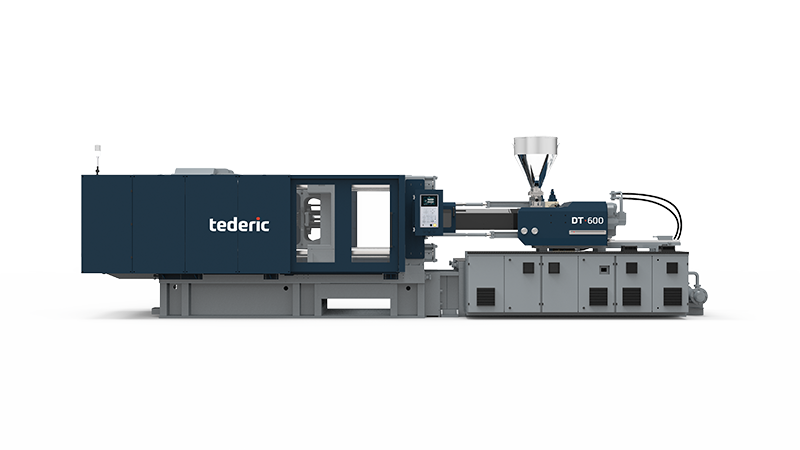

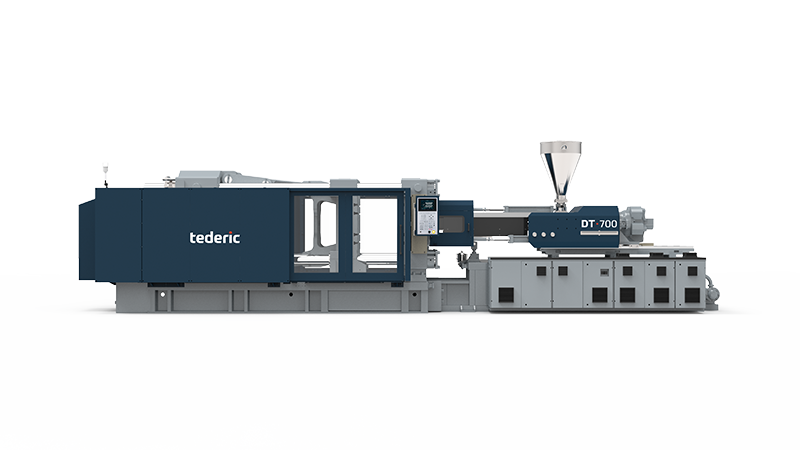

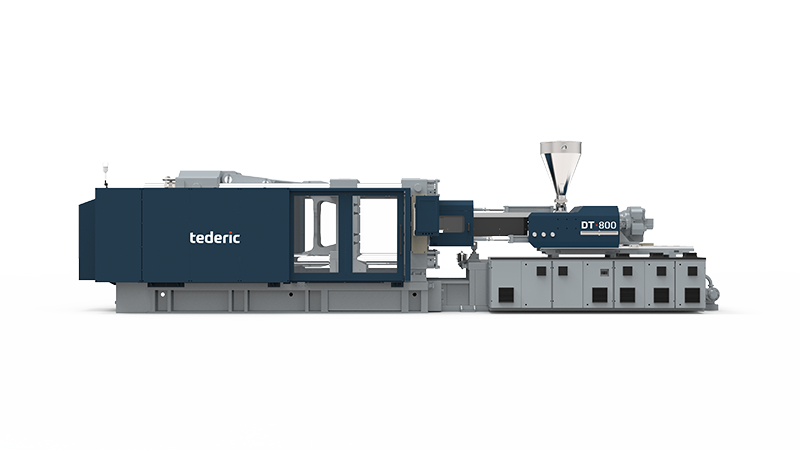

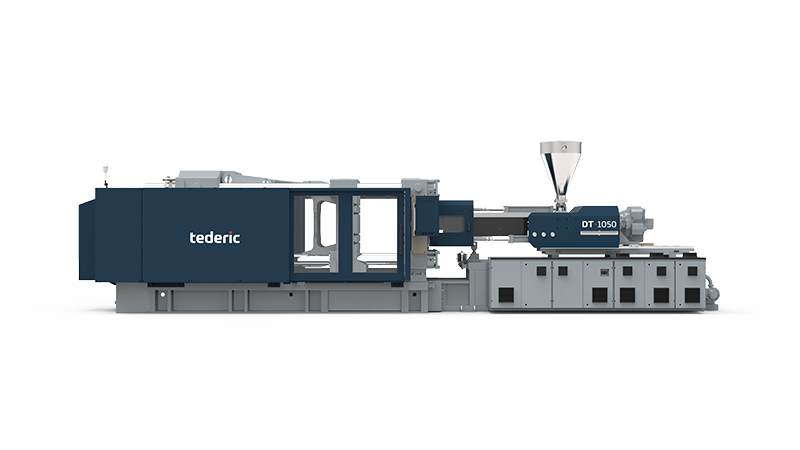

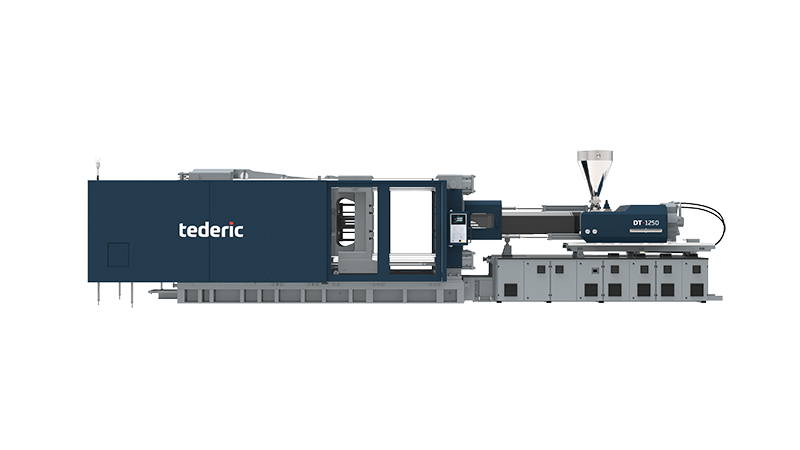

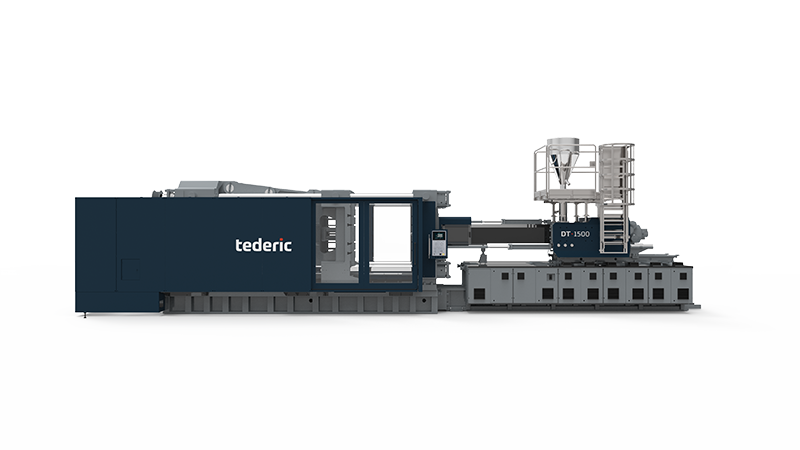

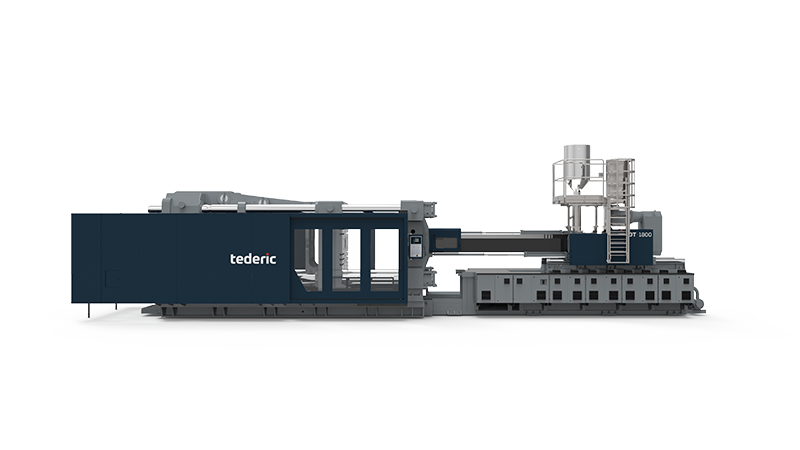

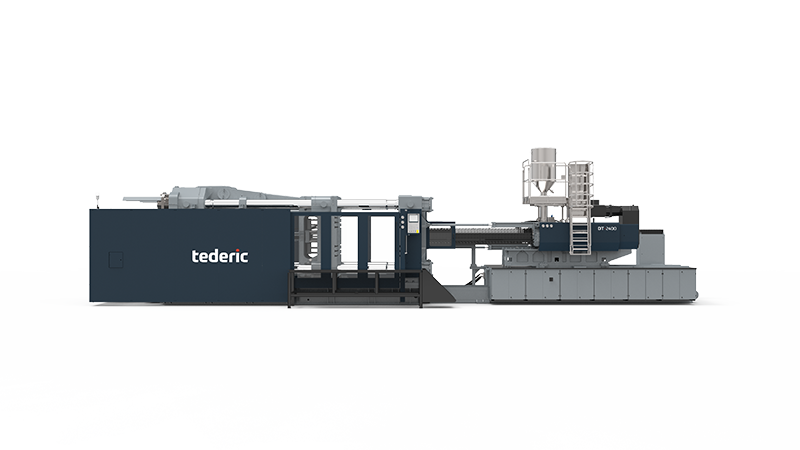

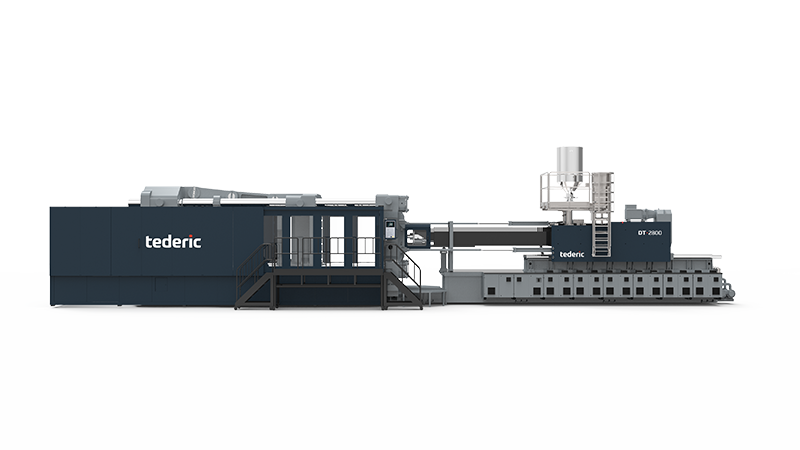

Hi-TECH MACHINERY offers a full range of Tederic PVC Injection Molding Machines, from the D100-i380 to the D2800-i66600 models. Whether you need a compact solution for medium-scale production or a high-output machine for large-volume PVC manufacturing, this series delivers outstanding performance. With energy-efficient operations, precise molding, and fast cycle times, the PVC Machine series ensures consistent product quality and cost-effective production, making it an ideal choice for businesses aiming to optimize their PVC component manufacturing.

The Tederic PVC Pipe Extrusion Line is specialized for high-speed, high-precision production of PVC components. It features a specialized plasticizing system designed for PVC, ensuring optimal material flow and product quality. The machine is built with an energy-efficient platform and an integrated cooling system to reduce cycle times and enhance operational efficiency. A powerful, high-torque pre-plasticizing motor ensures consistent and durable plasticization, even for complex PVC parts. With customizable settings and a full range of auxiliary equipment, the PVC Machine offers flexible solutions for diverse manufacturing needs, enabling businesses to improve productivity and maintain top-quality standards in PVC production.