The Tederic Pallet Injection Molding Machine is specifically engineered for high-volume production of pallets and large, complex parts. It incorporates the latest in hydraulic and electric technology, offering a perfect combination of speed, energy efficiency, and consistent performance. Designed to meet the demanding needs of industries such as packaging, logistics, and automotive, the Plastic Pallet Making Machine excels at manufacturing large, durable parts with outstanding precision and accuracy. Its advanced control system ensures stable performance, reduces energy consumption, and lowers overall production costs.

At Hi-TECH MACHINERY, we offer the Tederic Pallet Molding Machine to optimize your business’s output with minimal waste. This machine is ideal for large-scale operations looking to enhance quality and efficiency in pallet production, featuring fast cycle times, energy savings, and improved durability.

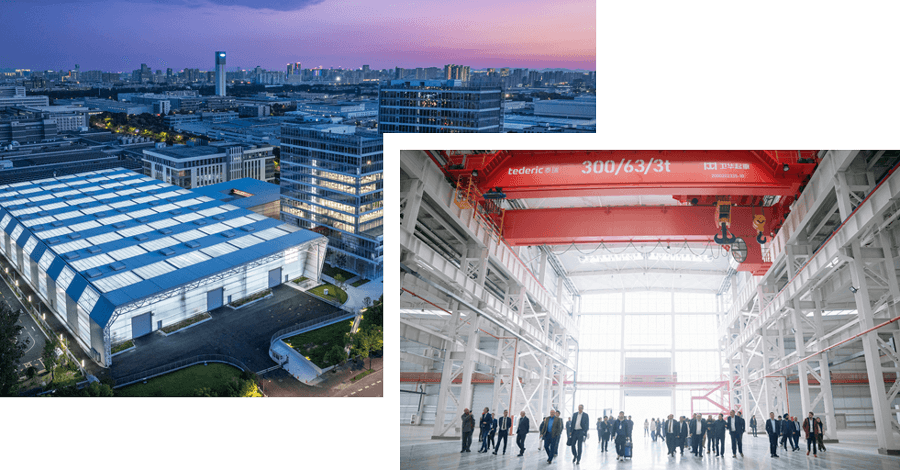

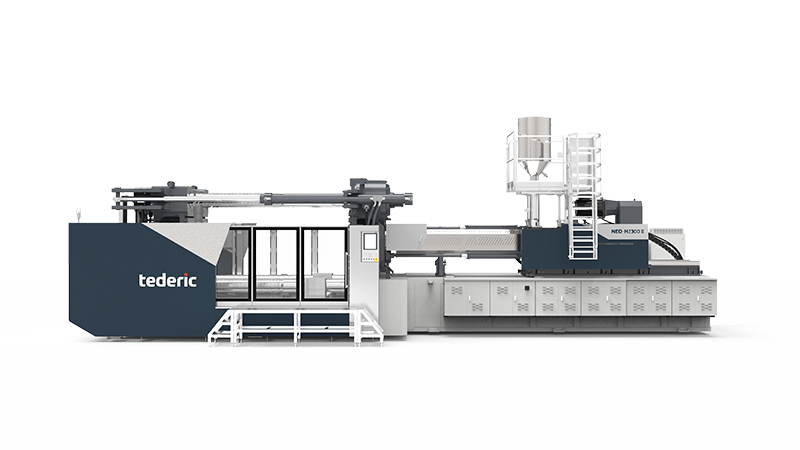

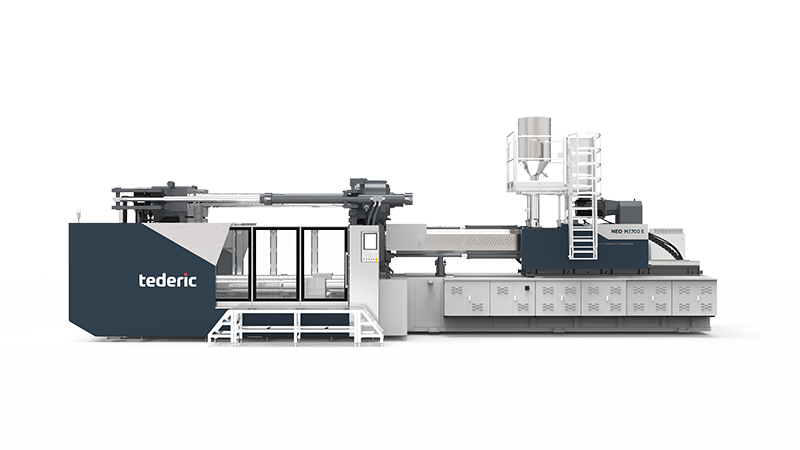

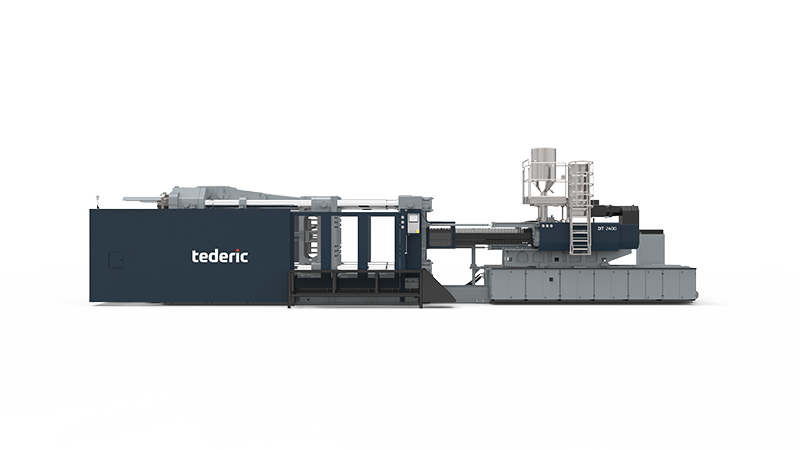

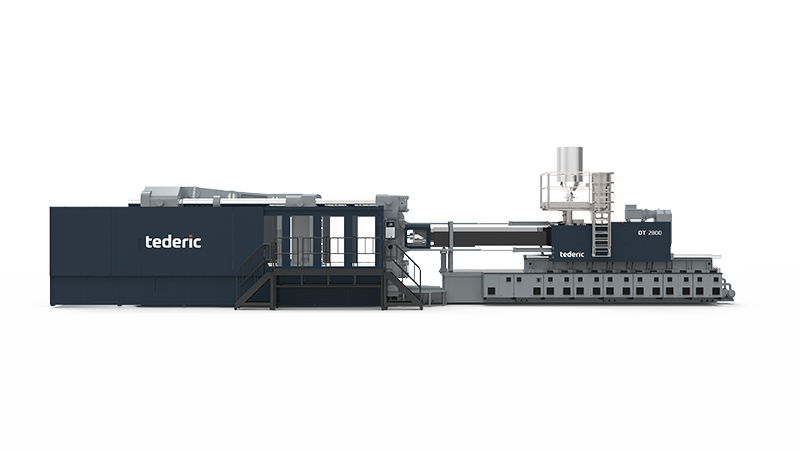

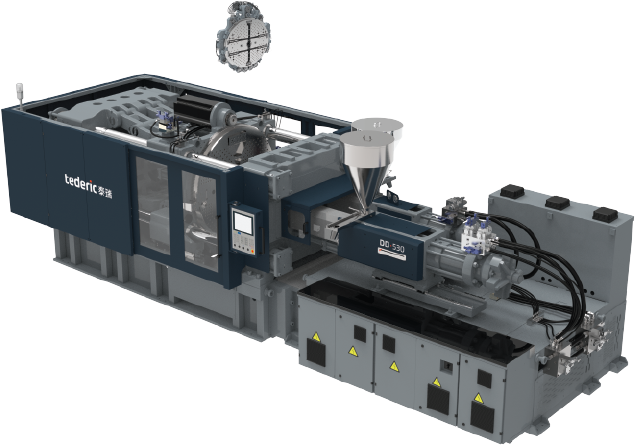

Hi-TECH MACHINERY offers a complete range of Tederic Pallet Injection Molding Machines, from the versatile Pallet H2300II-i38000 to the high-performance DT.2800-i80000 models. This series is engineered to meet the rigorous demands of industries such as packaging, logistics, and automotive, where large-scale production of pallets and bulk parts is essential. Whether you’re looking for an economical solution for mid-range production or a high-output, industrial-grade machine for large-volume applications, the Pallet series offers superior reliability and efficiency. With its advanced energy-saving features and precise molding capabilities, the series ensures consistent product quality and operational cost reduction, making it the optimal choice for businesses that require durability and high-volume output.

The Tederic Injection Molding Machine for Pallets is built for high-volume pallet production, featuring an advanced plasticizing system that increases speed by 20-30%, ideal for creating heavy-duty pallets. The machine’s robust mechanical structure, paired with the Keba controller, guarantees easy operation and consistent performance. With the inclusion of a servo power system for quick mold opening and synchronized movements, it significantly reduces cycle times. Additionally, its energy-saving features, such as oil-cooled electric charging, decrease energy consumption by over 30%, making it an ideal solution.