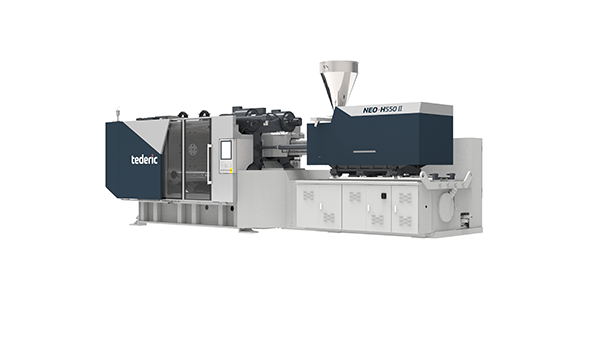

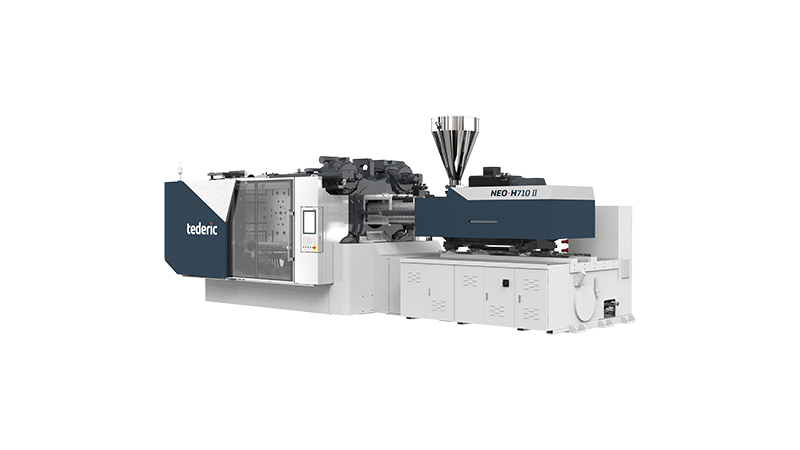

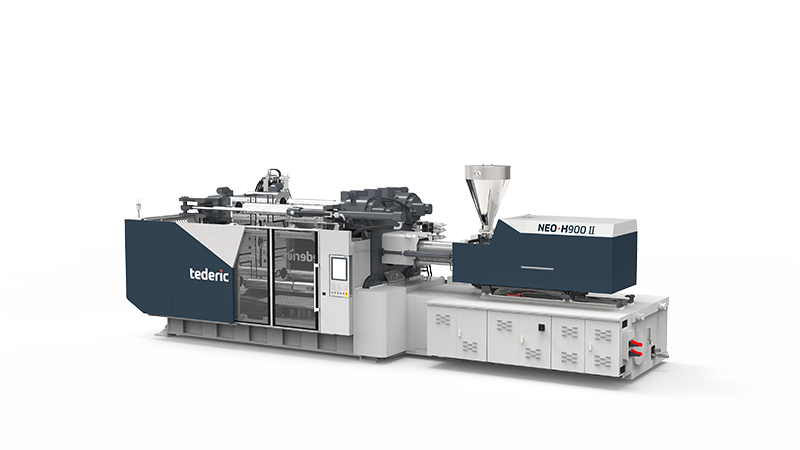

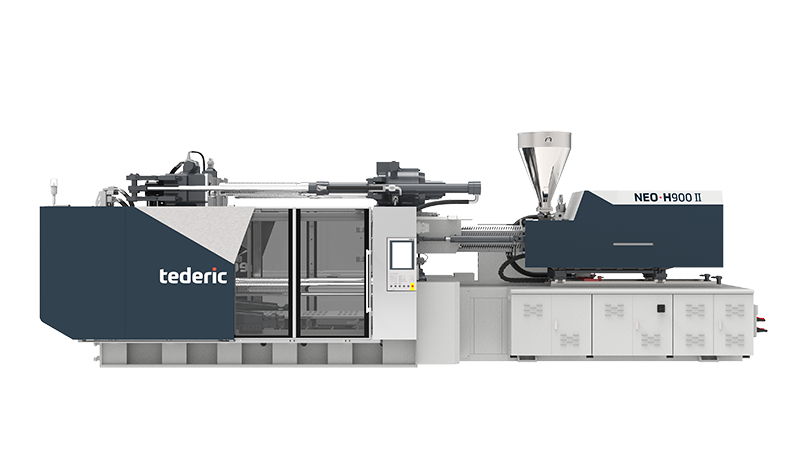

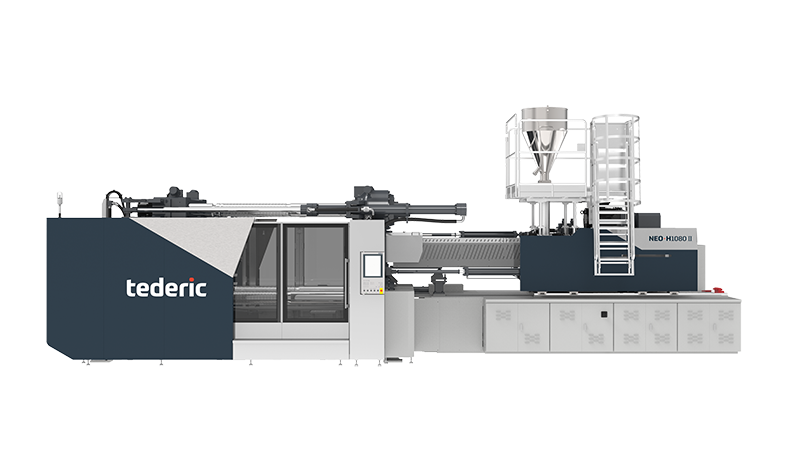

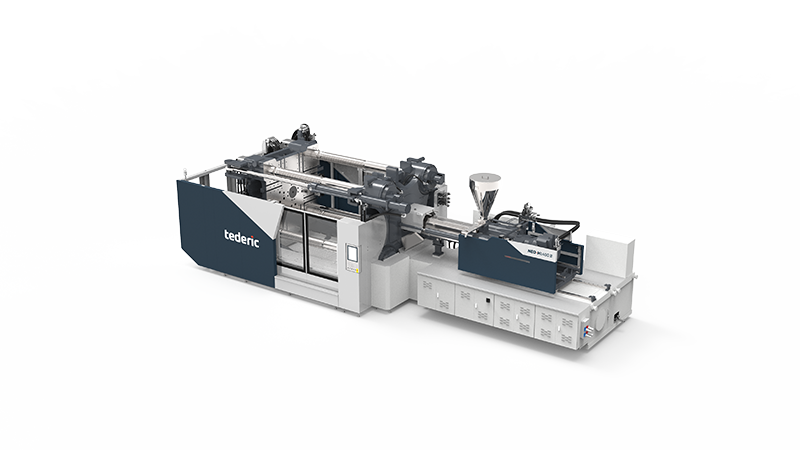

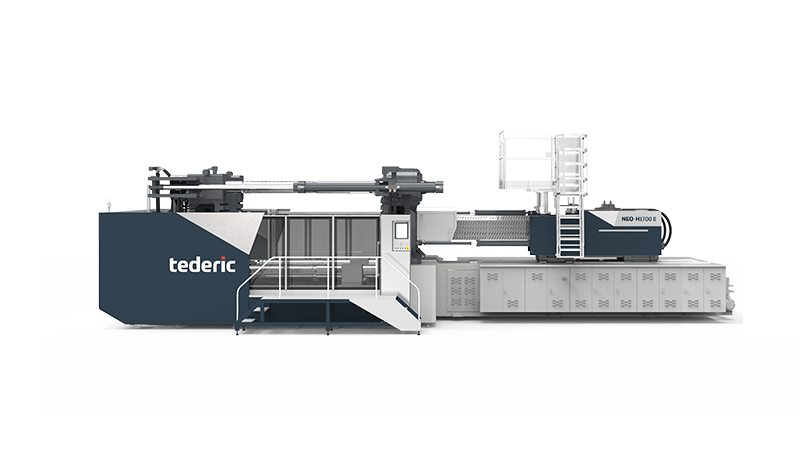

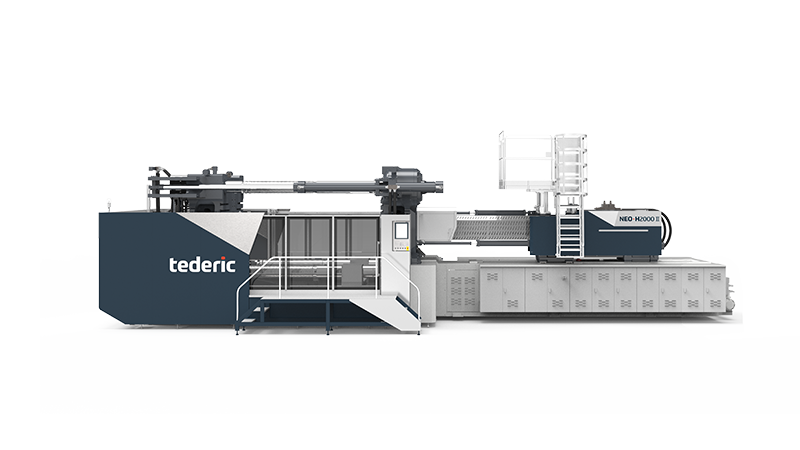

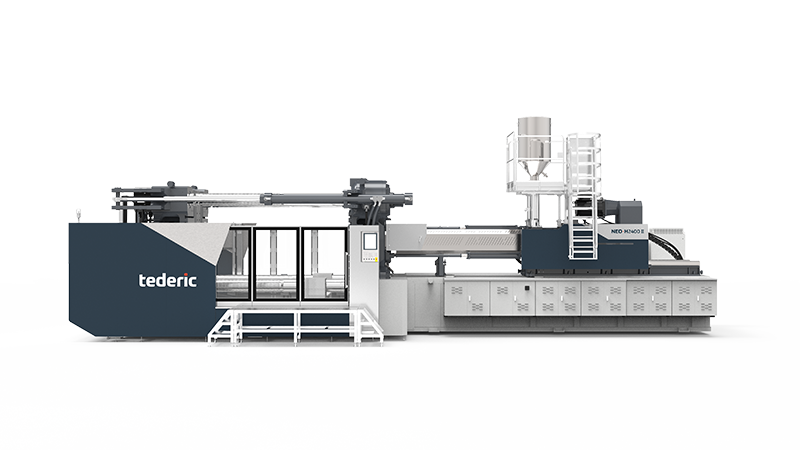

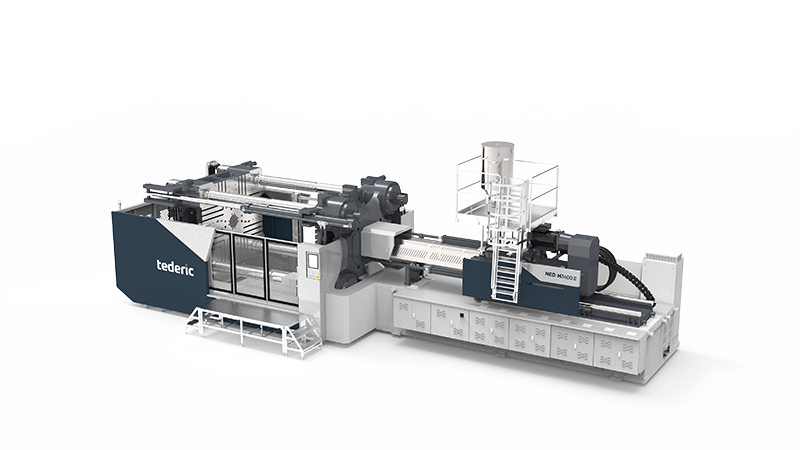

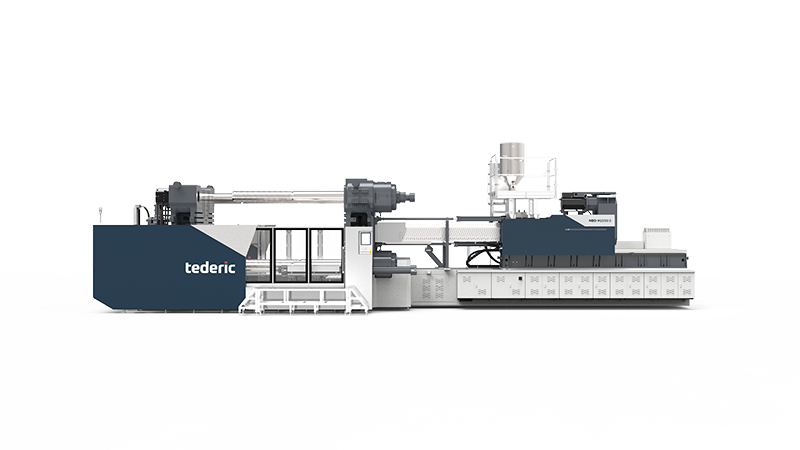

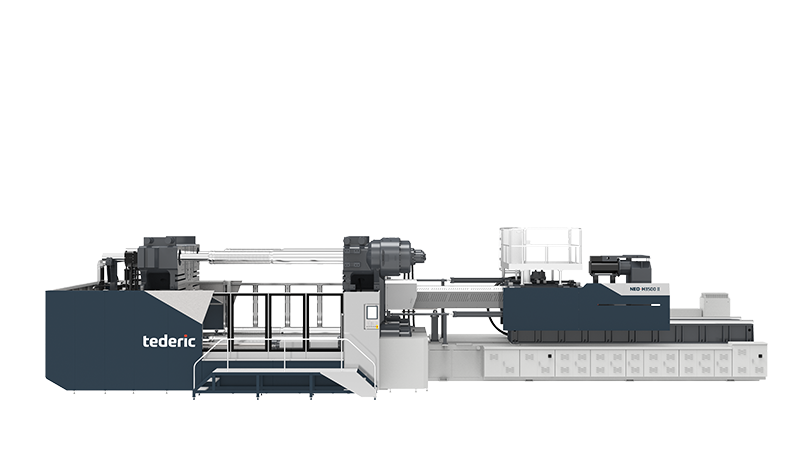

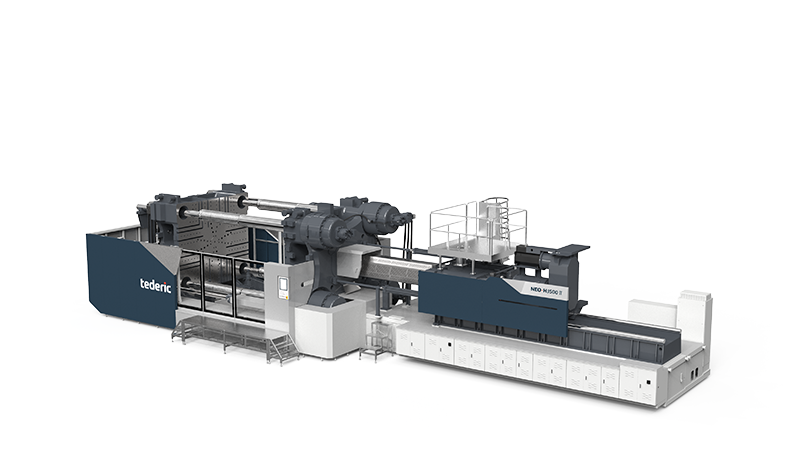

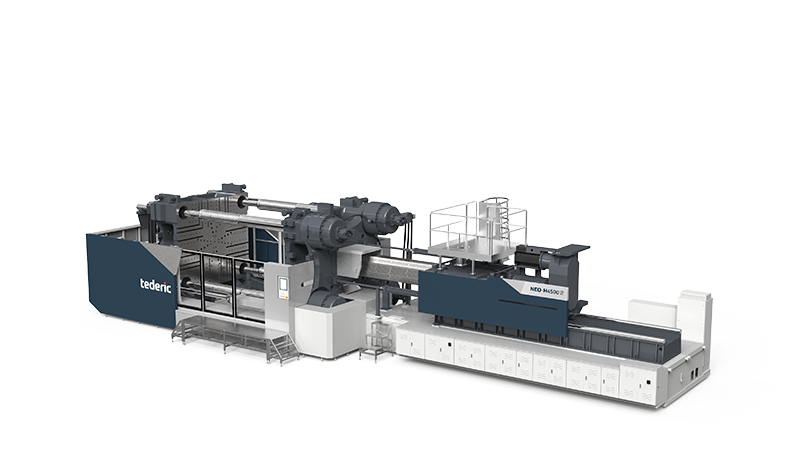

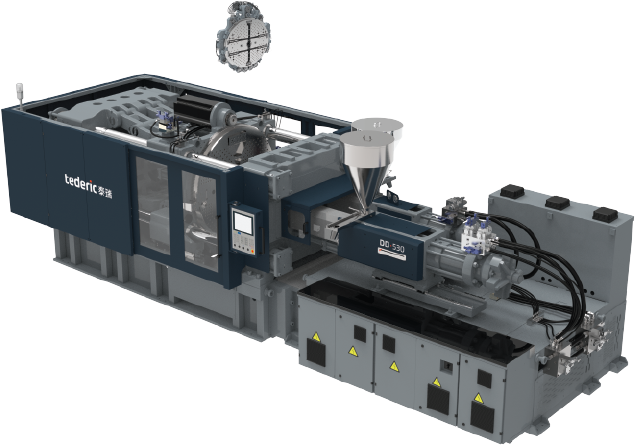

The Tederic NEO H2 Two-Platen Injection Molding Machine combines the strength of hydraulic technology with the precision of electric control, designed specifically for high-performance molding. This machine is optimized for demanding industries like automotive, packaging, consumer goods, and industrial applications. It stands out in large-scale production and complex mold applications, offering fast cycle times, enhanced stability, and exceptional part quality. The NEO H2 provides a unique balance of power, efficiency, and flexibility, enabling superior productivity and cost reductions in production.

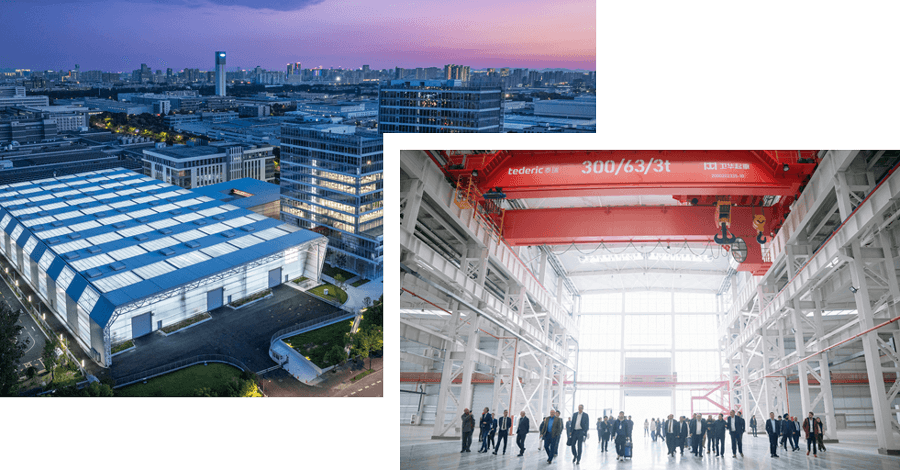

HI-TECH MACHINERY offers the Tederic brand, known for its engineering excellence and cutting-edge technology. With the NEO H2, businesses benefit from high-quality results, improved production efficiency, and greater energy savings in large-volume manufacturing settings.

HiTECH MACHINERY offers the complete range of the Tederic NEO H2 Machine Series, from the versatile NEO·H550II-i3800 to the high-performance NEO·H4500II-i22300 models. Each machine in the NEO H2 series is engineered for high-performance molding. Whether you’re looking for a reliable, cost-effective two-platen solution or a high-end machine with advanced hydraulic and electric technology, the NEO H2 series offers a perfect fit for your production needs. With its superior stability, energy efficiency, and exceptional molding precision, the NEO High-speed injection molding machine series guarantees outstanding product quality across a wide range of materials and complex applications.

The Tederic NEO H2 Two-Platen Molding Machine offers versatile, customizable solutions. Its advanced hydraulic system ensures precise, stable performance while effectively reducing energy consumption and minimizing maintenance needs. Designed for high precision and fast cycle times, the NEO H2 guarantees consistent product quality with significantly lower operational costs. The NEO H2 excels in applications where speed and reliability are crucial, delivering exceptional performance in demanding environments.