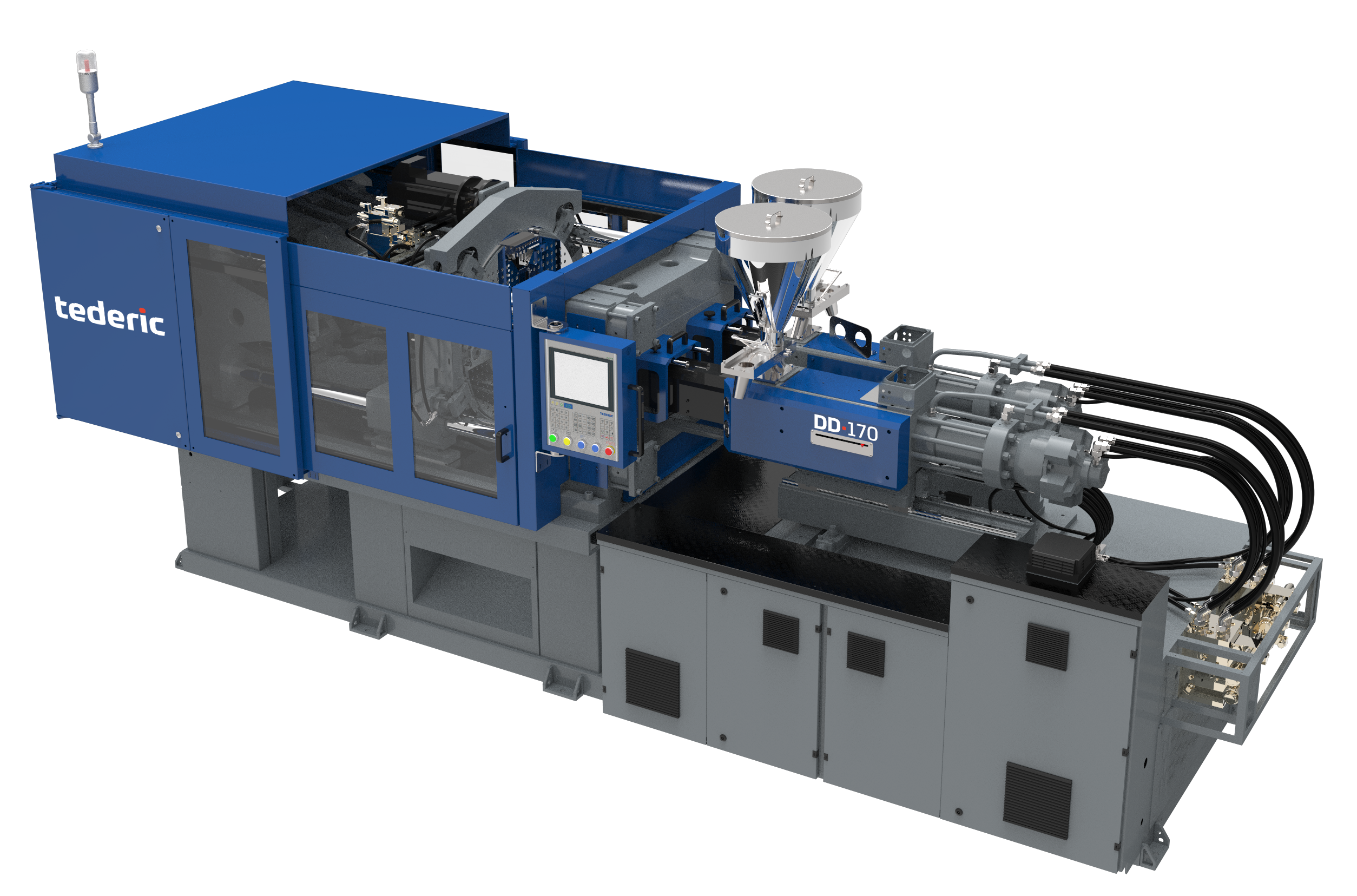

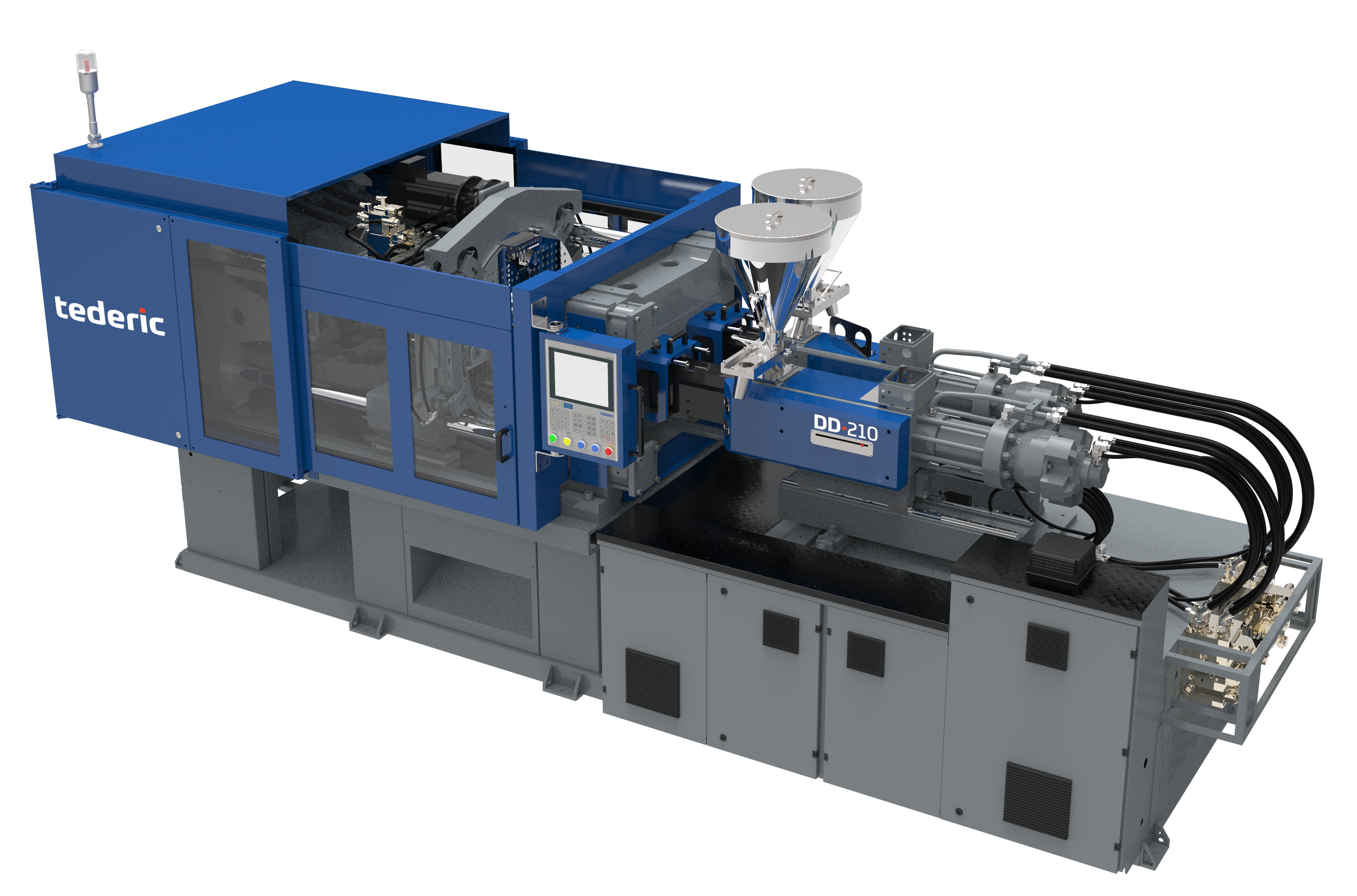

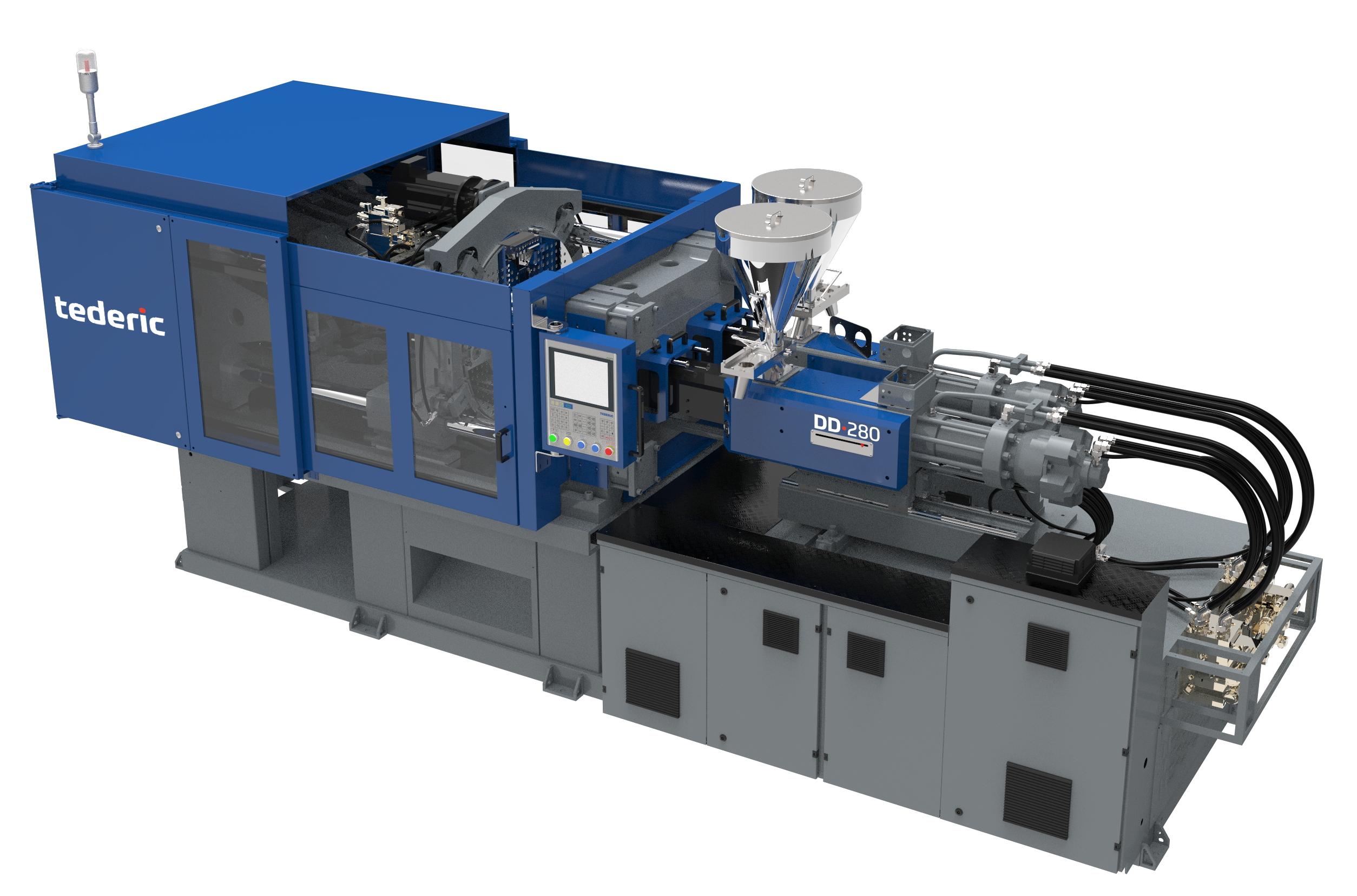

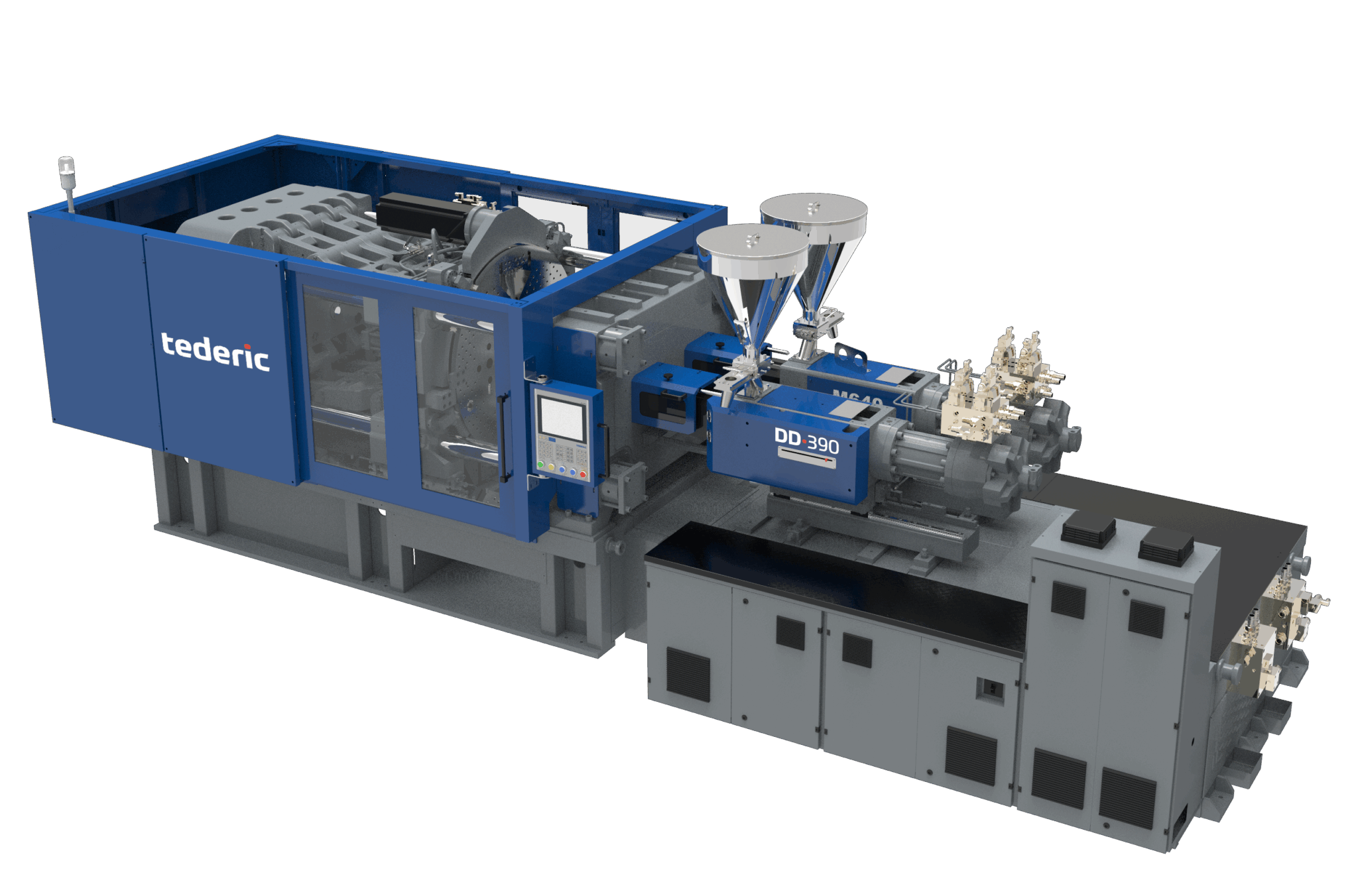

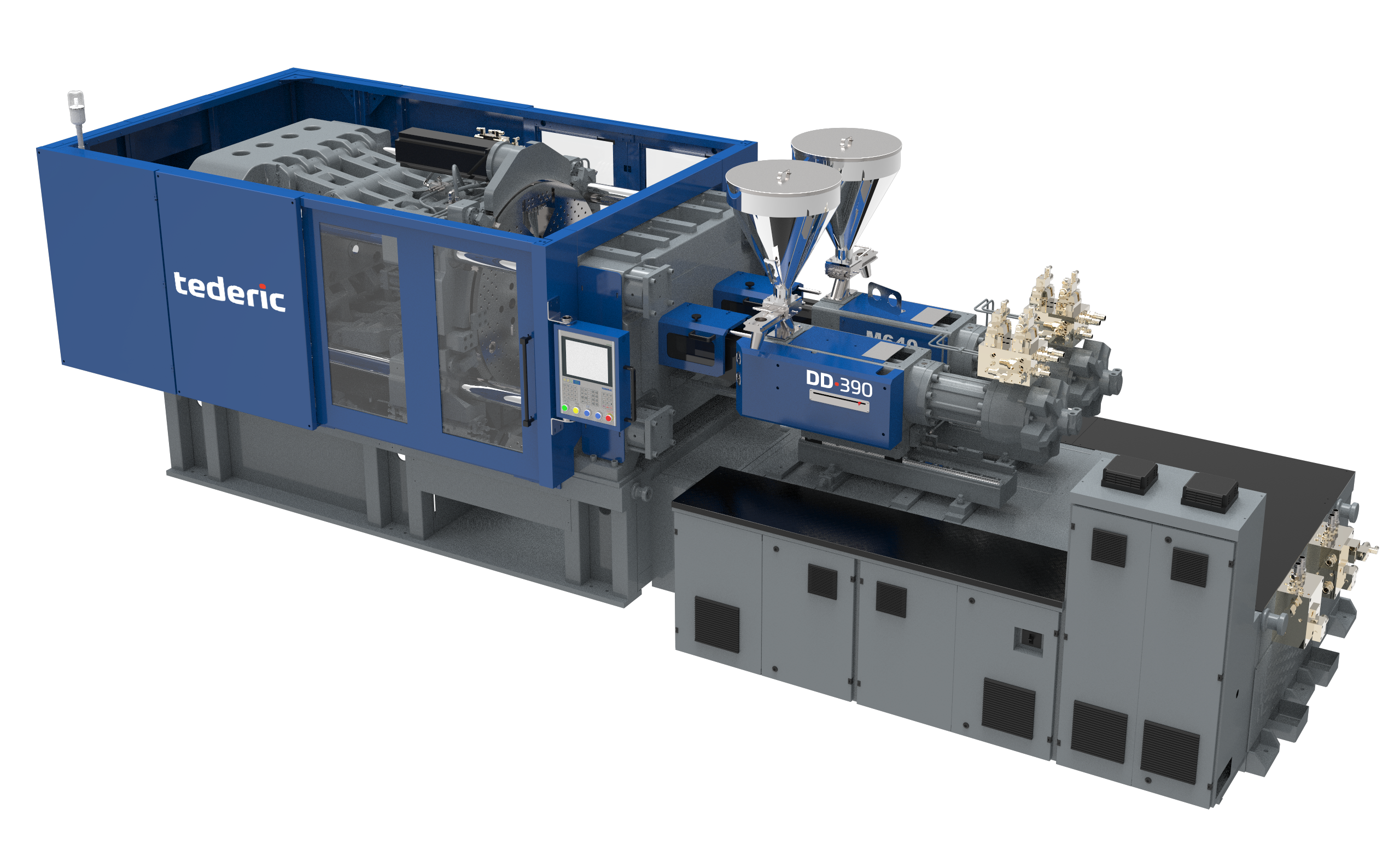

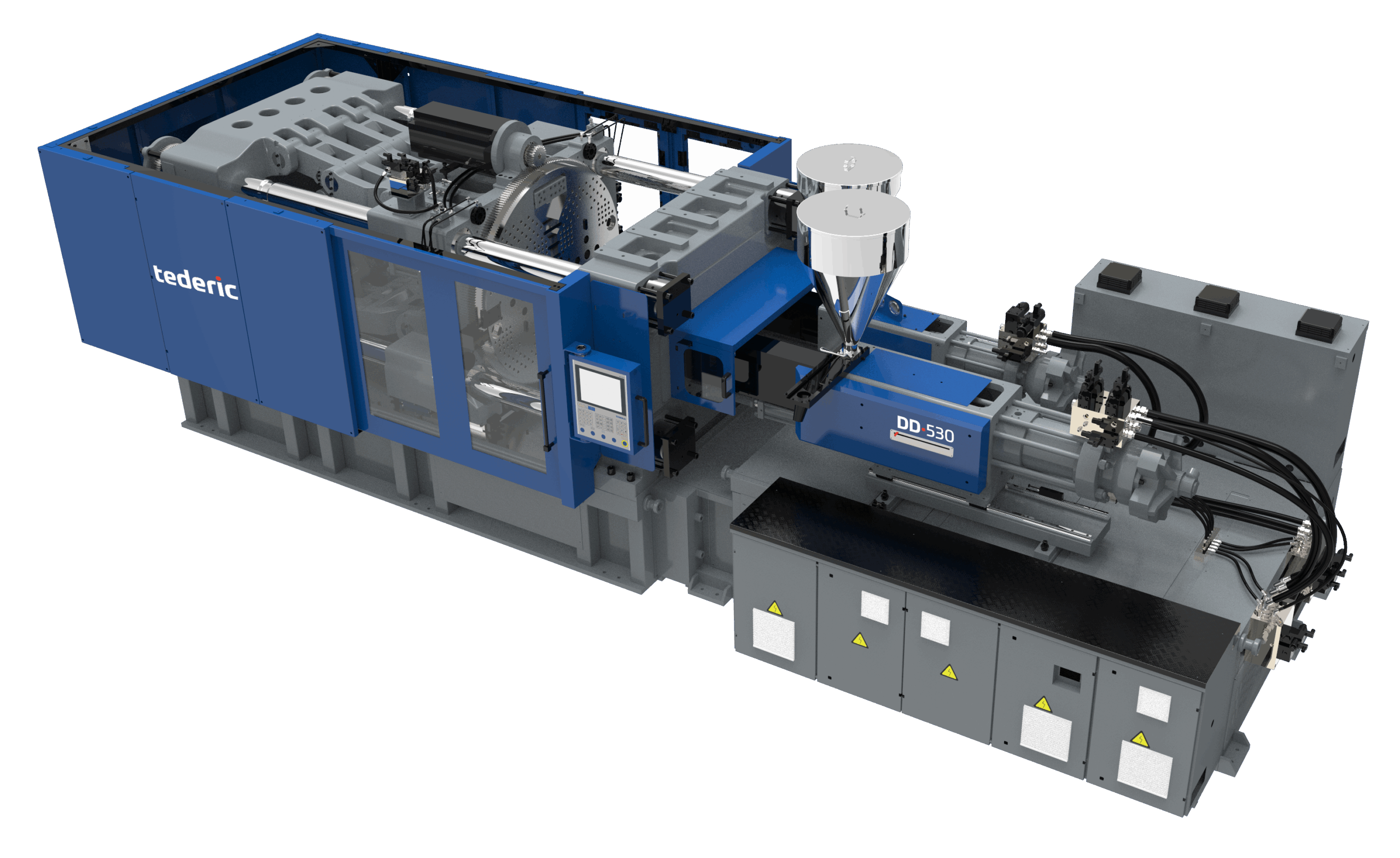

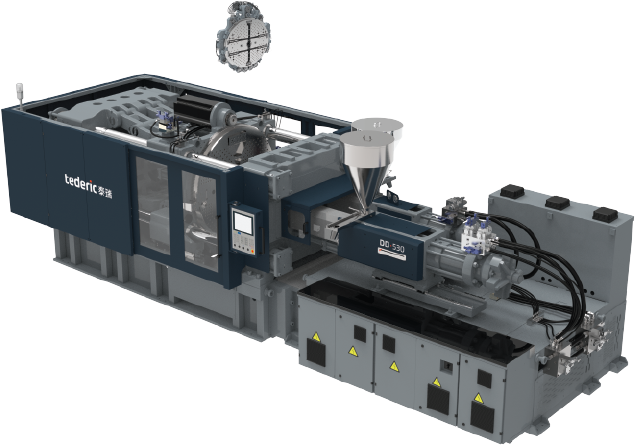

The DD Machine is a high-performance Multi-Component Injection Molding Machine, designed for the simultaneous molding of multiple components. Ideal for producing complex, multi-material parts, it is widely used in industries such as packaging, automotive, electronics, medical devices, construction, and consumer goods. This machine offers exceptional flexibility in material choice, enabling the creation of intricate parts in a shorter cycle time. Its ability to combine various materials into one part without compromising quality enhances overall productivity.

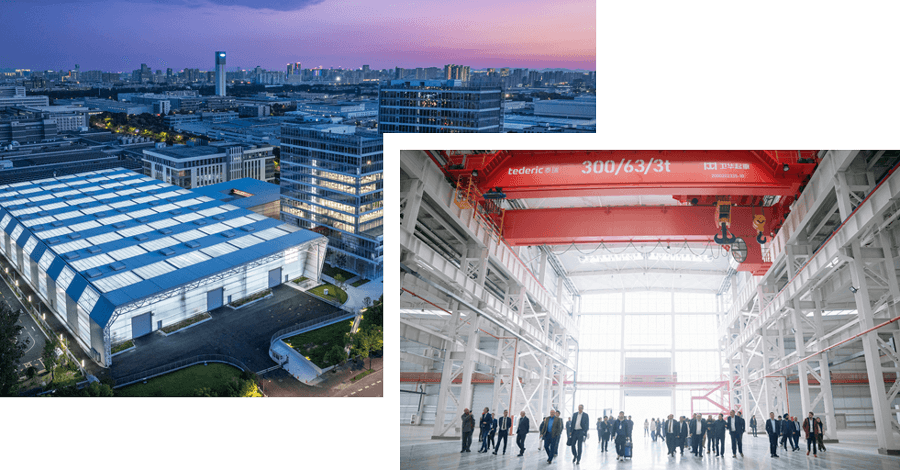

HiTECH MACHINERY is proud to present the Tederic brand, synonymous with precision, durability, and cutting-edge technology. With the DD Machine, businesses benefit from enhanced operational efficiency and superior product quality in a fraction of the time.

HiTECH MACHINERY offers the complete range of DD Machine models, starting from the entry-level D170Db-M150 to the high-performance D850Db-M2500. This series is engineered for the production of multi-material, multi-component parts, addressing diverse requirements. Whether you need a reliable, cost-effective solution or a high-end machine with advanced features, our Multi-Component Injection Molding Machines provide exceptional flexibility. They can efficiently mold multiple materials and designs simultaneously, ensuring superior quality, faster production times, and innovative solutions in every mold.

Tederic’s DD Series Injection Molding Machine offers a modular, multifunctional solution designed specifically for multi-component production. Equipped with Tederic’s exclusive Multi-Mold™ technology, it provides flexible, customizable options to meet a wide range of industrial demands. The two-platen clamping unit ensures precise mold alignment, and customers can choose between toggle or hydraulic systems depending on their specific needs. The injection unit, consisting of a hopper, barrel, screw, nozzle, and control system, efficiently melts and injects plastic for seamless multi-material production. Its hydraulic unit uses pressurized oil for smooth and high-efficiency operation, particularly excelling in large-scale, multi-color molding applications. This machine is ideal for industries requiring complex, multi-material parts with advanced molding capabilities.