MACHINERY SOLUTION

HiTech Machinery is a professional OEM manufacturer of injection stretch blow molding equipment based in China that serves the Middle East. Over the years, we have effectively integrated advanced technology and theories from domestic and international sources.

Our primary focus is designing, manufacturing, and selling a diverse range of fully automatic bottle-making machines and fully stretched blow molding machines. We offer a comprehensive selection with 4 wide series and over 40 different models.

HiTech Plastics’ high-quality, reliable stretch blowing machines are top sellers in over twenty provinces and are exported to Southeast Asia, the Middle East, Middle Asia, and South Africa. Clients consistently praise our machines and services.

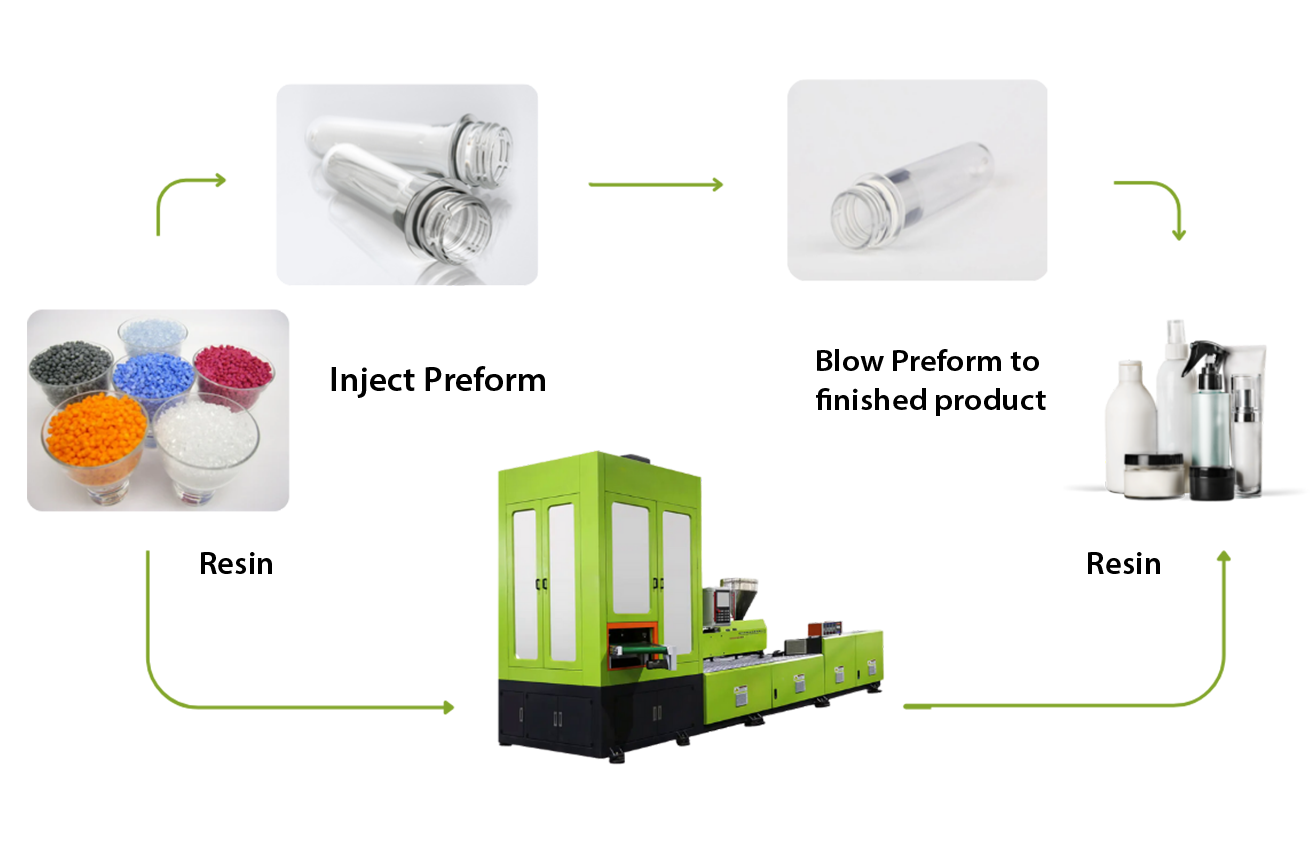

Injection Stretch Blow Molding Machine is a specially designed machine with a rotary three-station index, after performing an injection the performer will be sent to the below station, then stripped for the next processing like washing or filling needed by the conveyor. It is suitable for PE, PP, PS, SAN, EVA, COC, PEEK, TPU PETG, PET, etc material, with bottle volumes varying from LML-I000ml. The I.B.M. bottle has a perfect neck finish and strict body thickness and weight, it is good for high-quality packing like pharmaceutical, cosmetic, householding, and food products packing industries. HiTech has all of the necessary machinery for producing plastic products that you require.

This versatile stretch blowing machine is adept at processing a spectrum of materials, including PE, PP, PS, SAN, EVA, COC, PEEK, TPU, PETG, and PET, accommodating bottle volumes ranging from 1 ml to 1000 ml.rom pharmaceuticals and cosmetics to household and food products, the applications are limitless, delivering excellence in diverse packaging needs.

Experience the pinnacle of technological innovation with injection stretch blow molding state-of-the-art machines. Harnessing the latest advancements in artificial intelligence, our systems deliver unparalleled processing power, driving productivity and efficiency to new heights.

Injection stretch blow molding Machine is a specially designed machine with a rotary three-station index, after performing an injection stretch blow the performer will be sent to the below station, then stripped for the next processing like washing or filling needed by the conveyor. It is suitable for PE, PP, PS, SAN, EVA, COC, PEEK, TPU PETG, PET, etc material, with bottle volumes varying from LML-I000ml. The I.B.M. bottle has a perfect neck finish and strict body thickness and weight, it is good for high-quality packing like pharmaceutical, cosmetic, householding, and food products packing industries.

This versatile stretch blow molding machine is adept at processing a spectrum of materials, including PE, PP, PS, SAN, EVA, COC, PEEK, TPU, PETG, and PET, accommodating bottle volumes ranging from 1 ml to 1000 ml.rom pharmaceuticals and cosmetics to household and food products, the applications are limitless, delivering excellence in diverse packaging needs.

Our fully automatic stretch blowing machine, a one stop solution seamlessly manages the entire production process, from raw materials to final product, ensuring efficiency and ease of operation. Experience streamlined manufacturing with minimal human intervention.