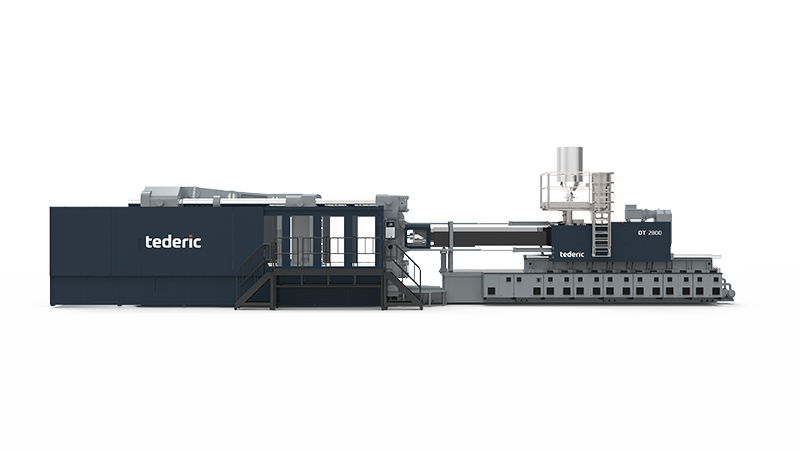

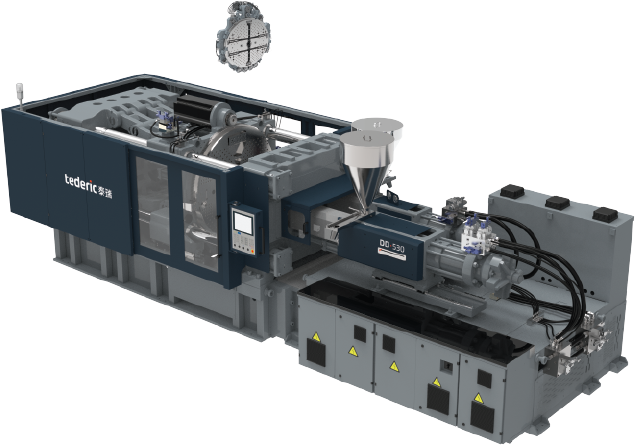

The DT Machine, featuring a Toggle Clamp Injection Molding system, is engineered for precise, high-quality production of molded parts across a wide variety of industries, including automotive, electronics, packaging, medical, construction, medical, construction, and consumer goods. Its toggle clamping mechanism ensures accurate mold alignment, delivering consistent and precise results. The machine excels in applications that require reliable performance, fast cycle times, and high dimensional accuracy for superior surface finishes.

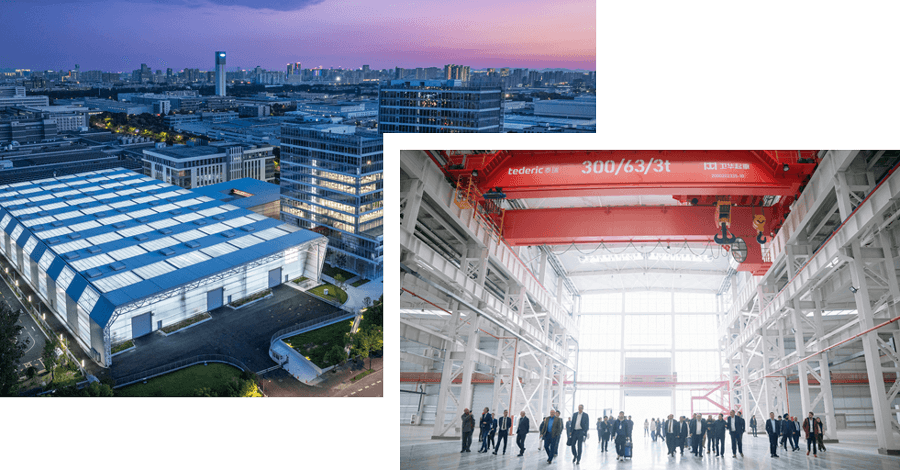

HiTECH MACHINERY proudly offers the Tederic brand, renowned for its unwavering commitment to precision and reliability. The DT Machine empowers businesses with faster production, excellent part quality, and enhanced operational performance, all while maintaining top-tier precision.

HiTECH MACHINERY proudly offers a comprehensive range of DT Machine models, from the entry-level D100i-380 to the high-performance D4000i-108000. Optimized for precise, single-material molding, the DT Machine series provides the perfect solution, whether you need a cost-efficient option or a top-tier machine with cutting-edge technology. These machines deliver exceptional dimensional accuracy, consistent performance, and superior quality, ensuring reliability and innovation in every mold.

Tederic’s DT Series Injection Molding Machine is designed for high-precision, single-material production. The toggle system ensures accurate mold alignment, which is crucial for achieving dimensional accuracy in each molded part. The injection unit, consisting of the hopper, barrel, screw, and nozzle, delivers consistent, high-precision material injection, making it ideal for single-color molding and high-tolerance applications. The hydraulic system supports reliable, cost-effective operation, ensuring efficient performance even in large-scale production environments. This machine is particularly well-suited for industries such as home appliances, logistics, and construction, where precision, speed, and efficiency are key to maintaining high-quality production.