JOBO MACHINERY MOLD CO. LTD

JOBO MACHINERY MOLD CO. LTD. was established in 1988 and Jobo focuses on the plastic cap manufacturing industry. Jobo people define ‘profession’ as ‘focusing on doing one thing for a long time. We believe that ‘less is more’.

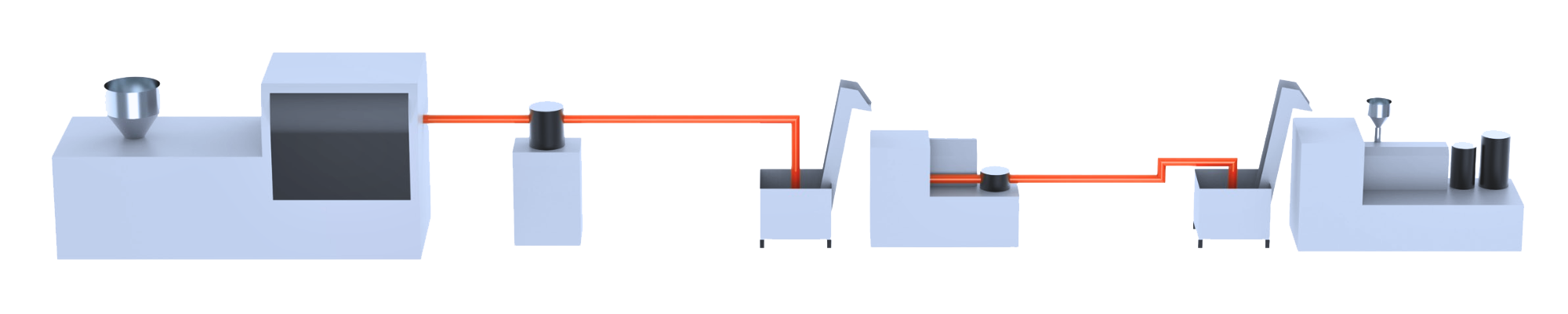

In 2007, the company successfully developed different specifications for hydraulic cap compression molding machines, dependent cap folding machines, automatic cap slitting machines, automatic cap lining machines, and bottle cap making machines.

The type of JF-30 BY hydraulic cap compression molding machine has applied for a national patent. In the year 2016, the company developed the second generation super speed cap compression molding machine (24 cavities), the speed of which can reach 40000 pieces per hour, it’s a significant development of this whole industry. HiTech Plastics can now fulfill all of your unique requirements.

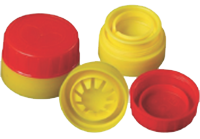

A plastic cap compression molding machine is a method used to manufacture caps that involves placing a preform of plastic into a mold and applying heat and pressure to shape the material. The finished plastic cap compression is then ejected from the mold. This method is often used to produce caps with complex shapes and designs and is suitable for medium volume production.

Plastic cap manufacturing is a process for producing caps and plastic products. Plastic material is heated, and molded under high pressure into the desired shape, creating a consistent and high-quality molded plastic bottle cap manufacturing machine with the desired shape, size, and structure.

The process of shaping plastic product material into a specific form using heat and pressure from a folding machine to create a plastic cap with a desired design. The cap manufacturing machine speed is synchronized to the cap compression molding machine it attached, effectively solving the problem of the cap anti-theft ring enfolding.

Jobo slitting cap manufacturing machine, combined with gas system, PlC auto control to tidy cap and output cap, also adjusts the depth of kerf and guard against theft ring height, is used to cut bottle caps and anti-theft rings making caps more tidy.

Plastic Bottle Cap Lining is the process of adding a liner to prevent contamination & leakage. Made of polyethylene/polypropylene. Fits inside the cap & provides a barrier between the contents & lid. Used for bottled products like beverages, pharma & cosmetics to maintain quality & prevent spoilage.

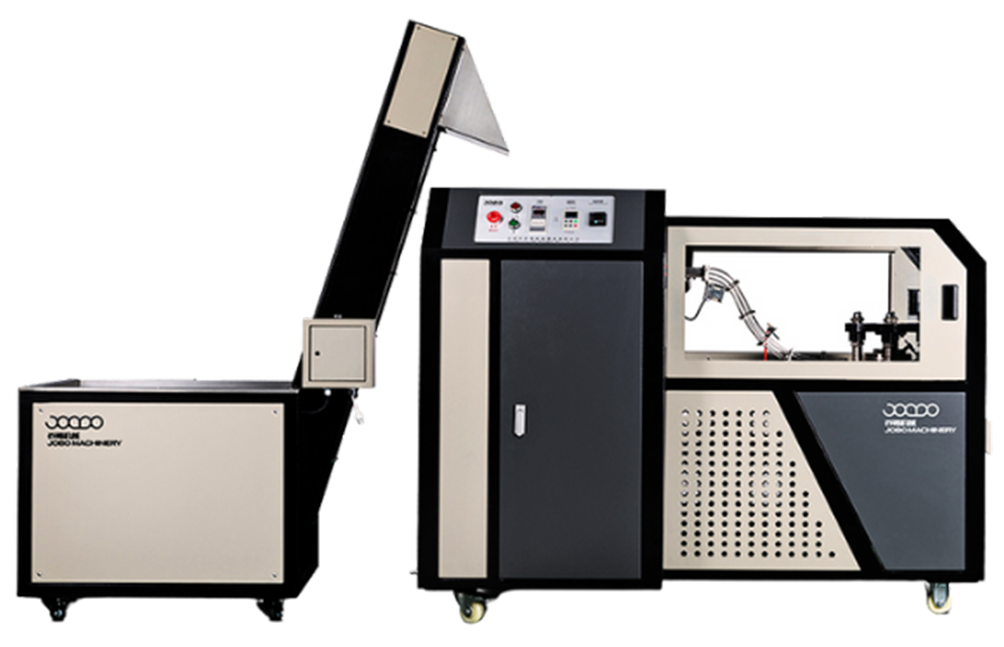

A cap compression molding machine is used to make bottle caps, soda caps, and water caps by high-temperature plasticizing. This machine is easy to operate, saving electricity, water, and labor costs. Compared with the same energy-consumption injection machine, the production can be grown three or four times. Besides, there is no wasted material. So it decreases the cost of bottle cap making greatly. All kinds of plastic manufacturing machines are available.

The HIGH Speed CMM JOBO-16C-24c-36c cap compression molding machine is now available. It is perfect for producing water and soda caps. It is simple to use, consumes less energy, water, and manpower than conventional injection machines, increases output three to four times faster, and produces no waste material, which lowers the cost of producing plastic bottle cap making machines.

Under the premise of the bottle cap making machine stability, we improved the cooling system and developed a new oil allocation system, which are the keys to improving the machine’s speed. In 2016 Jobo developed the second generation super speed plastic cap compression molding machine (24 cavities), the speed of which can reach 42000 pieces per hour, it’s a significant development of this whole bottle cap making machine industrial.

Specifications:

Capacity: 35000-42000 PCS/HR Maximum

Cap Diameter: 18-60 MM

Cap Height: 12-50 MM

Our plastic cap manufacturing machines, ranging from 7800 to 10200 pieces per hour up to 42000 pieces, offer tailored solutions from plastic cap compression to lining to meet diverse production needs.

The dependent cap folding machine was first invented by Jobo machinery, it is used to make the extension part of the plastic cap manufacturing anti-theft ring fold inward. The machine speed is synced with the plastic cap compression molding machine it attached, it effectively solved the problem of the cap anti-theft ring enfolding.

Specifications:

Capacity: 12000-42000 PCS/HR Maximum

Cap Height: 12-50 MM

Product Application

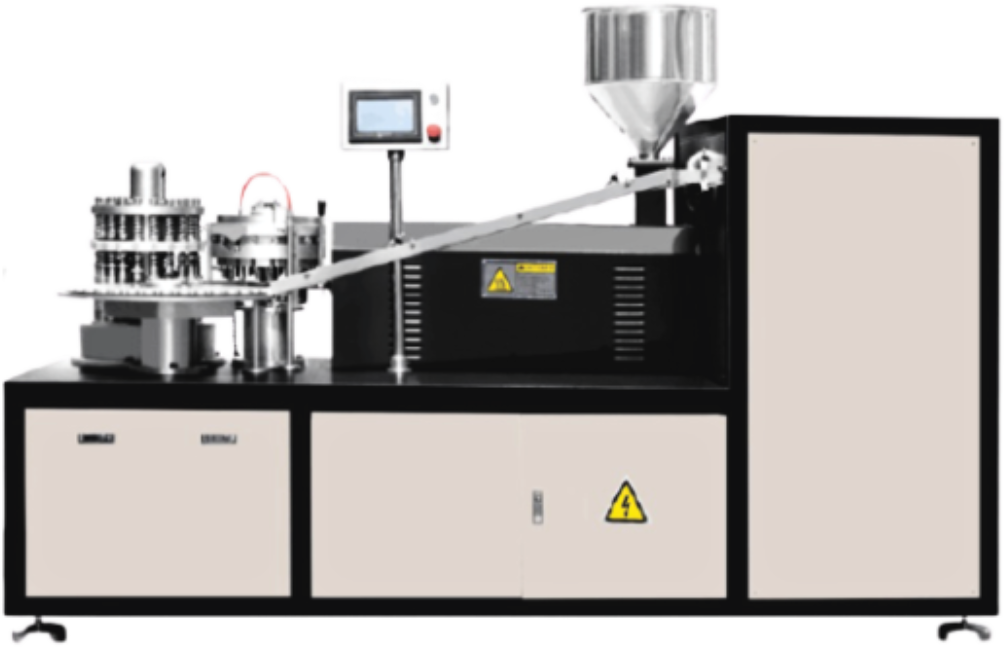

The JOBO slitting machine, combined with a gas system, PlC auto control to tidy cap and output cap slitting machine, also adjusts the depth of kerf and guard against theft ring height, is used to cut bottle caps and anti-theft rings making plastic caps more tidy and neat.

Capacity: 25000-40000 PCS/HR Maximum

Cap Diameter: 18-60 MM

Cap Height: 12-50 MM

Machine Size: L 1970 * W 860 * H 1270 MM

Machine Weight: 280KG

Product Application

The JOBO cap compression lining machine is used to produce cap liners by TPE plastic pellet, effectively solving the inner pad health and leakage problem. This machine is controlled by a PLC system, according to food hygiene standards of food leak and pressure resistance.

Cap Height: 12-50 MM

Machine Weight: 1200 KG

Product Application

What is a cap compression molding machine?

A cap compression molding machine uses the thermoplastic shaping process, continuous compression molding, wherein a precise dose of molten plastic is placed into an open mold cavity and compressed into shape as the mold closes. The material is formed under pressure, cooled, and released as a finished cap in a high-speed cycle.

What is the difference between compression molding and injection molding for bottle caps?

Plastic caps can be made via both injection and compression molding; the difference is in the production, output, and final characteristics. For standard bottle caps, compression molding is generally faster, more precise, and more resource-efficient. Injection molding is suitable for all types of caps, including standard, complex closures, flip-top caps, sports caps, and specialty designs. However, injection molding may leave a gate mark on the cap surface.

What is the cost of a new cap compression machine?

A cap compression molding machine often accompanies a complete setup of machines, including cap-slitting, -lining, and -folding machines, all synced together in one assembly. The actual price depends on the output and the number of mold cavities in the machine. Typically, a base setup starts at around $230,000. You can contact us for a customized quote.

What raw material is used in the compression molding of bottle caps?

HDPE (High-Density Polyethylene) is the most commonly used raw material for compression-molded bottle caps. It’s durable, food-safe, and works perfectly under heat and pressure. In some cases, Polypropylene (PP) is also used, depending on the cap type and application requirement.

What types of bottle caps can be produced on this machine?

HiTech Machinery’s compression molding machine can produce a wide range of caps, including mineral water, carbonated drinks, juice, edible oil, dairy, and pharmaceutical bottles. Our machines can produce caps with heights from 12 mm to 50 mm and diameters from 18 mm to 46 mm.

Does HiTech Machinery provide advanced bottle cap compression molding machines with local warranty?

Yes, one of the reasons businesses trust HiTech Machinery is the local support and warranty provided with our machines. Not only do we offer warranty coverage, but we also have a dedicated technical support team to resolve any issues that may arise promptly.

What is the production capacity (output) of a bottle cap compression molding machine?

It depends on the mold cavities and model. Currently, JOBO has introduced 16, 24, and 32 cavities, and a 48-cavity machine is also under development. The current production capability is around 42,000 caps per hour. However, the under-development machine is expected to produce between 50,000 and 70,000 caps per hour.

What is the power consumption of these machines?

HiTech Machinery’s bottle cap compression molding machines are servo-hydraulic and designed to save energy. They consume between 33 kW and 77 kW, depending on the model and production capacity.

What are the standard cap sizes?

The most common standard cap/Pre-form sizes include PCO1810 and PCO1881 (28 mm neck finish) and GME 30.40 (26/22). PCO1810 was common in earlier beverage packaging, while PCO1881 improved the design with a lighter, more material-efficient profile. GME 30.40 (26/22) is the newer lightweight standard developed to reduce plastic usage.

What is the ROI (Return on Investment) on this machine?

Considering the high-volume cap production setups, an investment of approximately PKR 65 million (USD 230,000) on a setup can be recovered within 18 to 24 months of regular production.