Injection molding machine applications spread across multiple industries. With specialized injection machine types and series, nearly every plastic product can be manufactured with precision.

Segments:

- Lighting

- Interior parts

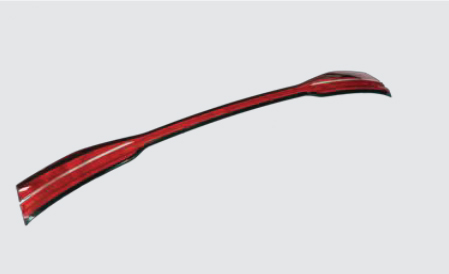

- Exterior parts

- Structural parts

- Glass decorative parts

Related technologies:

| PUR technology |

| In-Mold Decoration |

| Mucell technology |

| Injection molding compression |

| Multi-color technology |

| Electric sub-injection unit |

Main products:

| Two-platen IMM |

| Electric IMM |

| Horizontal turntable multi-component IMM |

| Vertical turntable multi-component IMM |

| |

|

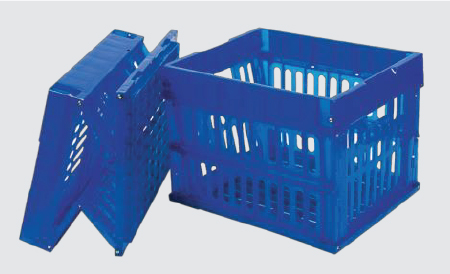

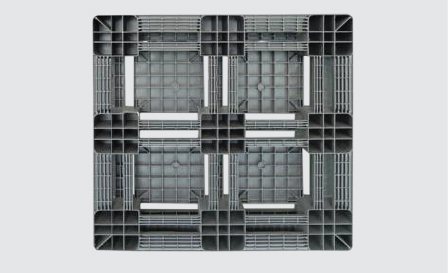

Segments:

- Pallets

- Crates

- Trash cans

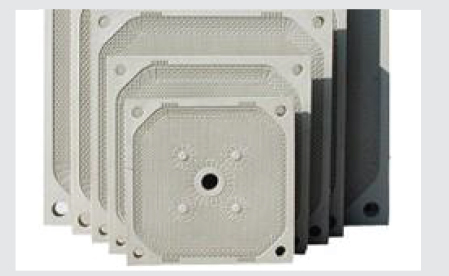

- Filter press plates

- Septic tank

Related technologies:

| Mucell technology |

| Tie bar retraction technology |

| Electric preplasticizing technology |

| Multi-color technology |

Main products:

| Toggle system IMM |

| Two-platen IMM |

Segments:

- Diagnostics

- Health care

- Pharmaceuticals

- Large medical equipment

Related technologies:

| Multi-color technology |

| Electric sub-injection unit |

Main products:

| Two-platen IMM |

| Electric IMM |

| Vertical turntable multi-component IMM |

Segments:

- Thin wall container

- Thick wall container & PET

- EDisposable tableware

Related technologies:

| PMulti-color technology |

| In-Mold Labeling |

Main products:

| Toggle system IMM |

| Electric IMM |

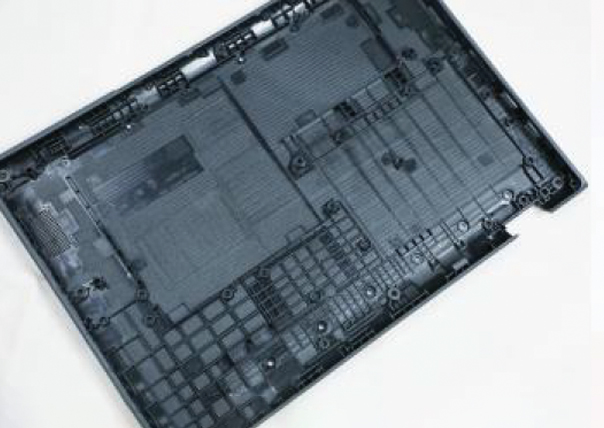

Segments:

- White goods

- Black goods

- Small household

Related technologies:

| Electric preplasticizing technology |

| Injection-blowing molding |

| Mucell technology |

| High-gloss processing technology |

| Multi-color technology |

| In-Mold Labeling |

Main products:

| Two-platen IMM |

| Electric IMM |

| Toggle system IMM |

| Two-platen IMM |

Segments:

• Consumer electronics

• Mobile communication

Related technologies:

| Electric preplasticizing |

| Injection-blowing molding |

Main products:

| Two-platen IMM |

| Electric IMM |

| Two-platen IMM |

| Vertical turntable multi-component IMM |

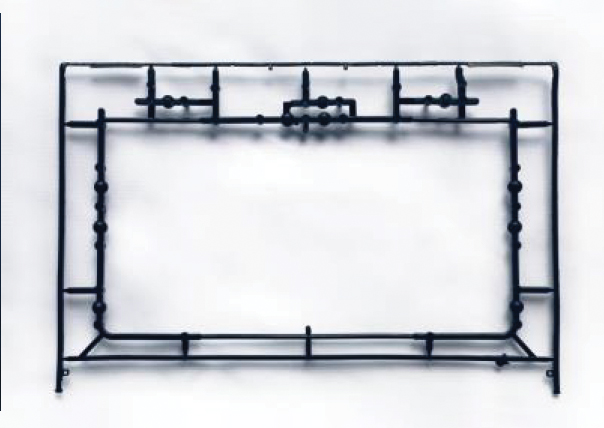

Segments:

- Rainwater collector

- Inspection wells

- PE fittings

- PVC&PPR fittings

Related technologies:

| Tie bar retraction technology |

| Electric preplasticizing technology |

| Mucell technology |

| Extra-large injection |

|

Main products:

| Toggle system IMM |

| Two-platen IMM |

Segments:

- Rainwater collector

- Inspection wells

- PE fittings

- PVC&PPR fittings

Related technologies:

| Tie bar retraction technology |

| Electric preplasticizing technology |

| Extra-large injection |

|

Main products:

| Toggle system IMM |

| Two-platen IMM |

Auxiliary Machinery

HiTech Machinery also supplies a complete range of auxiliary equipment to support injection molding machines, including hopper dryers, auto loaders, crushers, granulators, air compressors, chillers, color mixers, and mold temperature controllers.

What is the injection molding machine?

An injection molding machine (IMM), commonly known as plastic injection molding machine, takes in plastic/polymer pellets, melts them, and injects the molten material into a mold under high pressure. Once the plastic cools and solidifies, the part is ejected. This is the process behind almost all the rigid plastic parts and enclosures you see and use every day

What is a cost of an Injection Molding Machine?

The price of an injection molding machine varies widely depending on tonnage and type. Hydraulic machines are generally more cost-effective than all-electric ones. For example, a 100-ton hydraulic machine starts around 65 million PKR (~$20,000), while all-electric machines start at about $100,000.

What are the main components of an Injection Molding Machine?

An injection molding machine has three to four major parts. First is the injection and plastizing unit, where the plastic pellets are melted and pushed forward into the mold. Second is the clamping unit, which holds the mold. Third is the mold itself, customized for the required part. And the fourth is the hydraulic unit, which supplies the pressure and lubrication needed to move the machine’s running components

What is an injection molding machine used for?

Injection molding is used to make rigid plastic parts. For example, preforms for bottles, toys, enclosures, chairs, auto parts, and almost any other plastic part you use every day.

What is the cycle time for Injection Molding machine?

Cycle time is the time it takes to complete one molding cycle, from the mold closing to the part being ejected. Our machines have lower cycle times thanks to modern technology. However, cycle time is variable and depends on the mold design, cavity count, part geometry, and size. It could range from a few seconds to several minutes.

What is the difference between Hydraulic, Electric, and Hybrid Injection Molding Machines?

Hydraulic machines use hydraulic (oil) pressure for clamping and injection, are cost-effective, but less energy-efficient. Electric machines use servo motors only, making them precise, clean, and ideal for medical or food applications. Hybrid machines combine hydraulics with servo pumps to save energy while maintaining hydraulic power.

Is injection molding profitable?

Injection molding is generally a profitable business. HiTech Machinery has 2,000+ success stories of businesses that got their IMMs from us and have been producing multiple products, generating millions in revenue every month.

How do I choose the right Injection Molding Machine for my needs?

It depends on the part; its size, material, precision, and energy needs. Based on part size, we choose the tonnage and shot volume. At times, the machine is picked according to the material, since some materials need specialized screws. Very large parts may need a two-platen machine, and for medical-grade or food-safe materials, an all-electric machine is usually recommended.

What maintenance is required for an Injection Molding Machine?

It depends on the machine. All-electric machines need relatively little maintenance compared to hydraulic ones. Regular checks include cleaning the mold, lubricating moving parts, and inspecting hydraulic fluid levels. HiTech machinery offers technical support for such services.

Do you provide local warranty for machines?

HiTech Machinery provides up to 2 years local warranty on mechanical parts and 1 year warranty on electrical parts and screw barrels, provided that pure virgin material is used.

Do you deal in new or used injection molding machines?

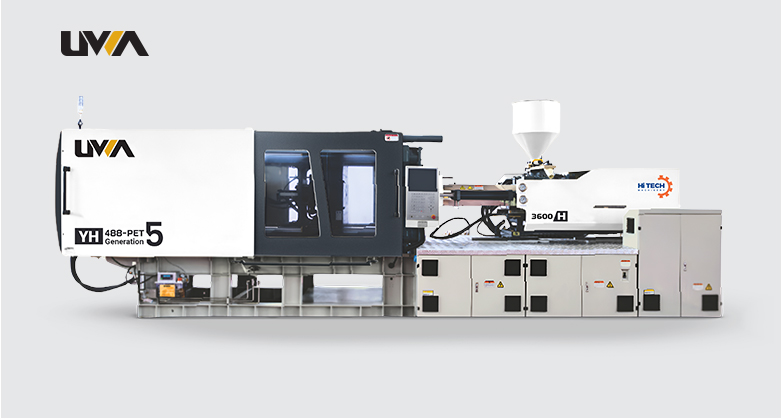

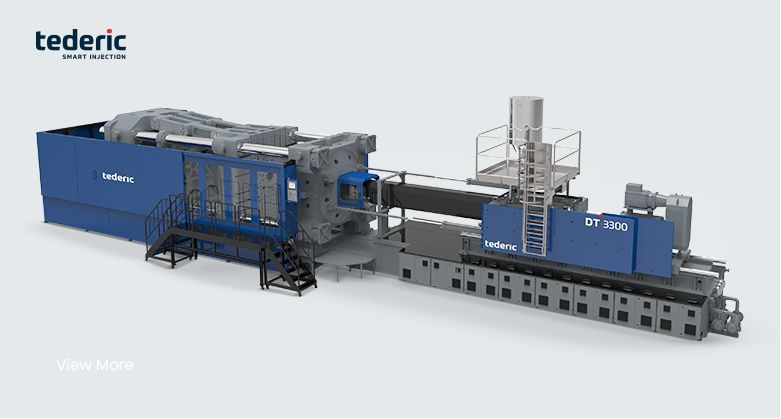

HiTech Machinery is a distributor of the latest new injection molding machines from Tederic and UWA. However, we also often have used machines available in stock.

What is delivery time of the injection molding machine?

We usually have standard models in stock, but delivery can take up to 100 days. This typically includes 50–60 working days for manufacturing and 30–35 working days for transit, after receipt of down payment and completion of all technical and commercial formalities.