We feel proud to announce that, in recognition of our excellent quality and high equipment standards, Hitech Plastics Engineering engaged in distributing production plant for variety of plastic items with round-the-clock emergency response 365 days-a-year.

Why Only Hi-tech Plastics Engineering?:

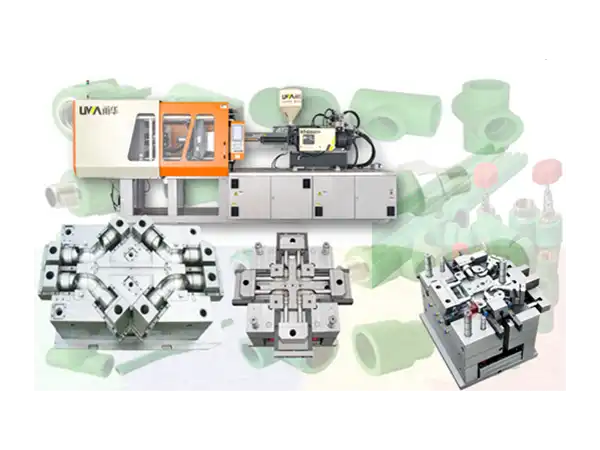

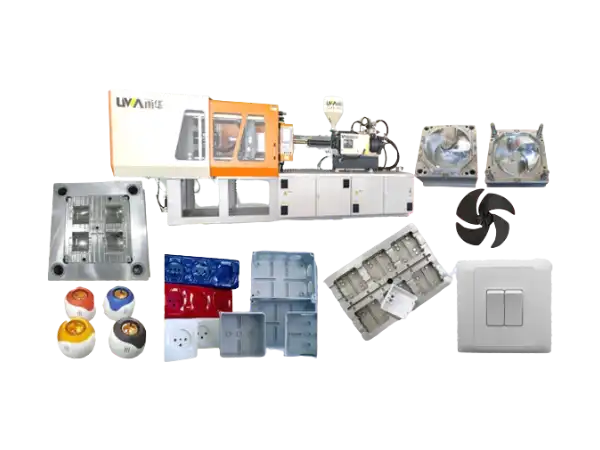

- Single Source Provider: You can get a range of options and can select best one.

- Consulting Specialists: They can help you determine the most effective equipment to increase your production throughput.

- Technical Assistance & Support: Hitech Plastics Engineering’s dedication to your project does not stop after installation. Our professionals are always ready to relieve burden from your shoulder and provide support even after office hours.

- Deals in World-Known Brands: As a authorized dealer of renowned brands, Hitech Plastics Engineering guarantee all equipment.

Double Color Injection Moulding Machine

Double Color Injection Molding Machine

- Servo system

- Screw platen

- Rotating platen

- 2 groups air valves & 2 groups core pulling

- Oil level alarm

- Self-lock suction oil filter

Mould Features:

- Double Color Mold 12 cavity

- Cycle Time: 20-30 seconds

- Production Capacity: 35000 – 50000 pcs per day

| D280Db/p/M370+M150 | |||

|---|---|---|---|

| Specifications | M370 | M150 | |

| Clamping Unit | |||

| Clamping Force | KN | 2800 | |

| Clamping Stroke | mm | 490 | |

| Tie Bar Distance | mm | 920*570 | |

| Max. Mould Height | mm | 520 | |

| Min. Mould Height | mm | 200 | |

| Eject Stroke | mm | 130 | |

| Eject Force | KN | 34 | |

| No. of Ejector Pins | Pcs | 3+3 | |

| Rotation Platen Diameter | mm | 1000 | |

| Injection Unit | |||

| Screw Diameter | mm | 38 | 25 |

| Screw L/D ratio | 20 | 22 | |

| Shot Size(Theoretical) | cm3 | 198 | 62 |

| Injection Weight (PS) | g | 181 | 56 |

| Injection Pressure | MPa | 189 | 309 |

| Injection Rate into Air | g/s | 114 | 70 |

| Injection Stroke | mm | 175 | 143 |

| Injection Speed | mm/s | 101 | 126 |

| Screw Rotation Speed | rpm | 218 | 304 |

| Others | |||

| Max. pump pressure | MPa | 17.5 | 17.5 |

| Pump Power Motor | KW | 13+13 | 13+13 |

| Heater Power | KW | 6.6 | 4.5 |

| Hopper capacity | kg | 25 | 25 |

| Oil tank capacity | L | 350 | 350 |

Double Color Tufting Machine

High Speed Double Color Tufting Machine

- Operating Speed 850 r/min

- Taiwan linear guide rail system

- Fuji, Japan electronic control system

- Stuffing holes diameter: 1.2-3.1 mm (special Diameter can be customized) | Distance of Holes Jumping is 8 mm.

- Control computer can store more than 500 kinds of toothbrush variety data.

- Unique mechanical motion parts with precise positioning

| Tufting Machine | |||

|---|---|---|---|

| Specifications | |||

| Power Input | AC single Phase 220V 3KW | ||

| Air Consumption | 0.6 ~ 0.8 Mpa | ||

| Machine Size (mm) | 1220 * 880 * 1340 | ||

| Packing Size (mm) | 1400 * 1200 * 1600 | ||

| Gross Weight | 750 KG | ||

| Channels | Double | ||

| Position Accuracy | 0.02mm/100mm | ||

| Tufting Speed | 850 holes per minute | ||

| Tufting Length | 10-15 mm | ||

| Dia of Tufting Holes | φ 1.2 ~ 3.0 mm | ||