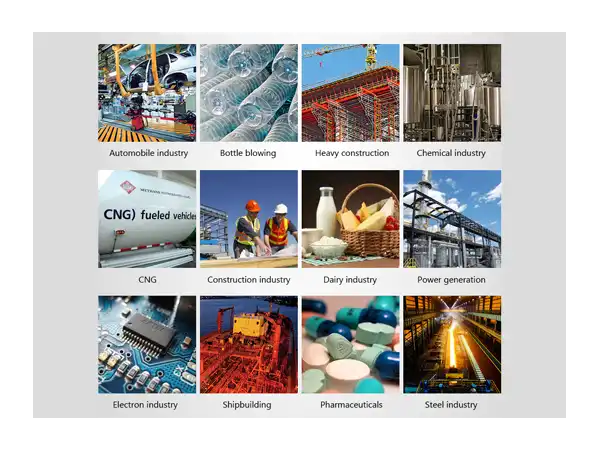

Uses for Air Compressors ” Application of Air Compressor”

Many places utilize air compressors. Gas stations employ pressurized air to inflate and deflate tyres. You may have seen gas-powered air compressors on trailers operating jackhammers and concrete compactors.

You’ve undoubtedly seen air compressors. They’re in your fridge and arena’s HVAC system.

Air compressors improve home and business upkeep, pleasure, and efficiency. We’ll miss certain compressed air usage. We’ve listed many uses for air compressors.

Compressor uses vary. Most air compressors are reciprocating piston or rotary screw.

Major Applications

-

Household Compressed Air

-

Powerful Air Compressor for the Garage

-

Compressed Air Use in Business

-

The Benefits of Compressed Air

-

New applications for air compressors

-

the advantages of compressed air

-

Heat recovery, which improves productivity,

-

Alternatives

1-Household Air Compressors

Compressed air has various personal uses. Having a home air compressor makes numerous maintenance duties easier and allows for creative hobbies and professional art. Sizes and power of reciprocating pistons cover any residential purpose.

Most small shops and homes utilise reciprocating piston air compressors. These increase air pressure by decreasing airspace.

If you’re familiar with an internal combustion engine, you’ll understand a piston air compressor. The cylinder, valve head, crankshaft, connecting rod, and piston compress air for the storage tank. This air compressor may be driven by an electric motor or gas engine, allowing for distant usage and mobility.

Most household air compressors may be wheeled or transported. A larger fixed tank is preferable for a home shop with pneumatic equipment. In the reciprocating piston design, there are single-stage and two-stage variants. Two-stage models give a more powerful air supply with a higher PSIG rating.

2-Powerful Air Compressors for the Garage

Any home workshop will need an air compressor. An air compressor helps with wood, outdoor power equipment, precise painting, and your own automobile.

Home air compressors

People utilise compressed air for fun and domestic tasks. Compressed air is used for hobbies, maintenance, and repairs.

Simple air pumps increase airflow for tasks like:

Air compressors inflate car and bike tyres, pool toys, airbeds, and athletic equipment. Cleaning siding, brick, and paths Milder cleansers Experts and beginners would struggle without compressed air. Sanding helps wood contract. Portable, lightweight household compressed air nailguns for wood and metal. Compressed air airbrushing for motorcycles, automobiles, and RVs DIY pneumatics Air-blow gun cleaning Yard work using air compressors Directed air pressure cleans tight equipment cracks. Drain puddles Weed widely

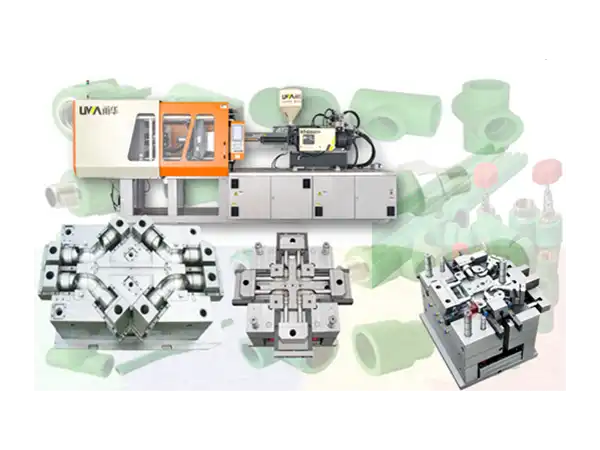

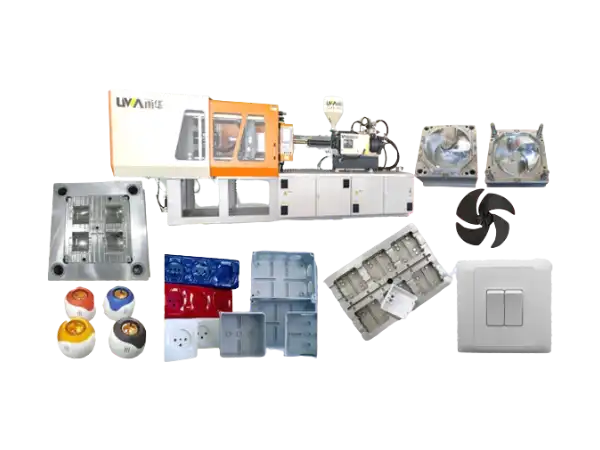

3-Compressed Air Use in Business

Compressed air is needed for a small companies and industrial applications. Compressed air is a stable and efficient power source for many organizations’ equipment and products. Smaller businesses may provide better, faster services with an air compressor, from inflating tires to manufacturing.

Compressed air needs of small and medium-sized businesses

In smaller firms, reciprocating air compressors power pneumatic tools. These tools are lighter and safer than electric ones. Continuous usage of electric tools might cause overheating or shorting.

Air-powered equipment are becoming more widespread in small firms, notably in the construction industry. Nearly every electric power tool uses compressed air.

Small engine repair, vehicle servicing, entertainment, and dentistry treatments can all use compressed air. Producing compressed air may be expensive, so you should know how to get the proper volume at the optimum pressure for the least expense. It takes 7 or 8 hp of electrical energy to create 1 hp of compressed air energy.

Quincy Compressor builds its products with energy efficiency and the environment in mind. Our models provide significant savings over standard air compressor designs.

SMBs use air compressors for the following:

Auto body painting

Auto body or woodworking sanding

pneumatic roofing nail guns

Dentistry and medicine

Construction using pneumatic drills and hammers

Automotive shop air tools

Cleaning with a blowgun

Machine shop and factory sandblasting

4-The Benefits of Air Compressors

The Benefits of Compressed Air

Some industries require a consistent, heat-free power supply. Since the first mechanical air compressor was constructed in the early 1800s, compressed air systems have been essential. After electric, water, and gas.

This need has a superior air compressor and vacuum technology. Quincy Compressor manufactured high-quality air compressors 100 years ago.

As industrial compressed air demand grew around 1970, we utilized rotary screw technology. Energy exploration, food processing, and manufacturing need efficient performance. Compressors increase pressure and volume. Each model is specialized for manufacture.

Both of our air compressors are industry-best. Industrial air compressors have various applications.

- AGRICULTURE/FARMING

Compressed air delivers long-lasting performance and minimal ownership costs for profitable farming. Used for:

Conveyors move feed and grain between silos.

Greenhouse ventilation

Crop-spraying

Dairy machine power

Pneumatic material handling

- MANUFACTURING

Manufacturing

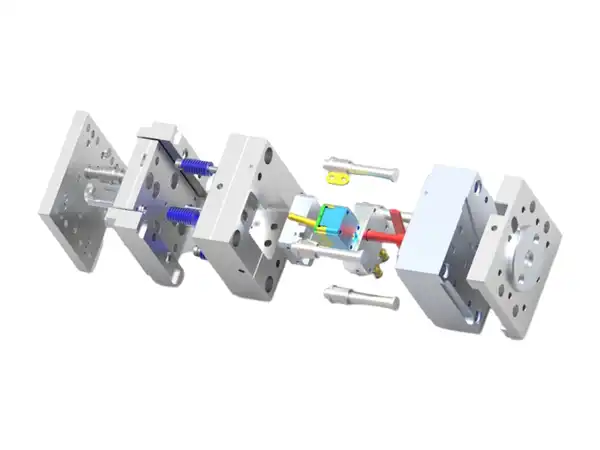

Refineries, plastics, assembly, and metal fabrication use air compression. Manufacturers use air compressors to:

Airline tools

Cutter-welders

Mold-ejection

Monitoring production

Roller/feed adjustments

Gas or bottle explosion

Screw and nut-turn

Air cylinders increase production efficiency by powering positioners, clamps, air chucks, and air knives.

Finishing and packing using pneumatic liquid cushioning, carton stapling, appliance sanding, dry powder transportation, and fluidizing.

Finishing/sandblasting metal

Controlled automation

- Dry-cleaning

Dry cleaning requires a reliable air supply and system for quality garment cleaning. Used for:

Cleaning guns deliver chemicals

Laundry presses, steam cleaners

- PHARMACEUTICAL

Remaining clean, dry and oil-free are important requirements for this highly regulated business that demands accurate equipment and high-performance systems. A pharmaceutical air compressor system operates by:

Moving goods on conveyor systems

Pharmaceutical coatings

Maintaining tank pressure

Packaging products

- ENERGY EXPLORATION

Energy exploration requires reliable electricity to reduce repair and maintenance expenses. A compressor:

Energy exploration requires reliable electricity to reduce repair and maintenance expenses. A compressor:

Onshore and offshore pneumatic equipment power

Adjusting for swells

Reactor rod insertion/removal

Remoting steam and coolant valves

Boiler house ventilation

- NUTRITION

All food and beverage facilities require air compressors. They need contaminant-free compressed air. Purpose:

Food palletization Check bottle filling End-users have more control over use and air quality with on-site compressed air. 9/10 makers use pressurized air.

5-New applications for air compressors

Due to the large list of air compressor uses above, you can imagine that this tool has many characteristics that make it appropriate for a wide range of uses.

Here are several benefits of compressed air with examples:

Pressurized air doesn’t interfere with electrical monitoring devices in operating rooms.

Smaller tanks can contain compressed air for scuba divers.

Pressurized air tools can be used to maintain furnaces and industrial freezers.

In isolated places, compressed air can be stored in application-specific tanks to power snow-making devices.

Air compressor uses

We’ve covered many household and commercial uses for air compressors, but there are a few others you should know about. Some non-traditional air compressor uses are mentioned below.

- DIVING

- HOSPITALS

- AUTOMOBILES

- RAILWAYS

- PLAYGROUNDS

6-The Advantages Of Compressed Air

People don’t realize how common compressed air is.

Air compression generates power for homes, businesses, and industries. Compressed air is costly to produce, but it reduces production costs in other ways, therefore it’s required in almost every manufacturing and industrial context.

What makes a “expensive” utility popular?

Air tools are useful. Lighter and more durable in dirty, regular usage. Reduced user strain boosts productivity and efficiency.

Electric equipment struggles in steel mills and foundries. High heat and grime overwhelm and break electrical devices. Air tools are indestructible and low-maintenance.

Compressed air may be stored. Power spikes may burst fuses and harm industrial equipment. Install a variable-use air compressor. Correct system offers pressure and storage tank for reliable energy.

7-Heat recovery, which improves productivity

Compressor systems may recover heat from compression to reduce the cost of compressed air. This heat can be utilized for space heating, heating process water, lubricants, or other manufacturing fluids, or supplying hot water for plant locker room showers.

Space heating may recover up to 94% of a compressor system’s input power. Many enterprises might use the high expense of creating on-site electricity via air compression to save money elsewhere.

8-Alternatives

In certain dangerous places, only compressed air provides power. Platforms, mines, and tunneling equipment are flammable. Electricity’s heat and spark potential don’t mix well with these circumstances, but compressed air offers a cost-effective alternative.

Compressed air solves industrial issues. Compressed air makes activities simpler, cheaper, and safer in mining, manufacturing, and construction.

As a 100-year-old air compressor manufacturer, we’ve kept up with technology to tackle manufacturing challenges. Through innovations, breakthroughs, and opportunities to help other industries grow, we’re dedicated to delivering legendary performance and reliability for another century. Learn more about our excellent items by contacting us or a local sales and service specialist.